Titanium alloy and steel dissimilar metal tungsten electrode argon arc fusion welding process based on copper-nickel composite middle layer

A technology for compounding intermediate layers and dissimilar metals, applied in metal processing equipment, arc welding equipment, manufacturing tools, etc., can solve the problem of reducing the mechanical strength and service reliability of titanium/steel joints, differences in thermophysical properties, and low metallurgical solid solubility and other problems, to achieve the effect of no defects in weld formation, wide welding process window and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

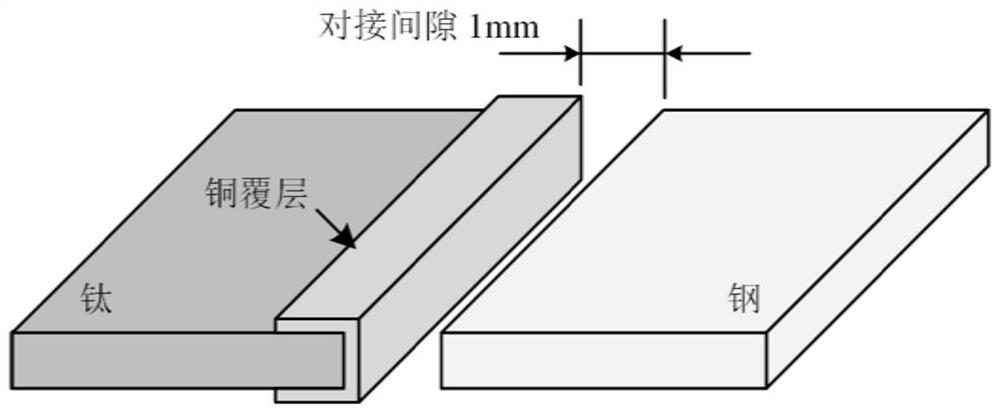

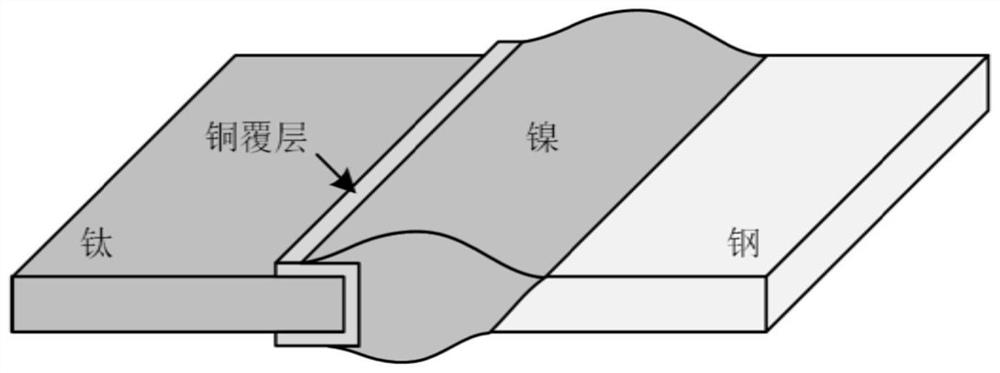

[0033]Step 1: Take TC4 titanium alloy and 304 stainless steel plates with a thickness of 1mm, length and width of 200mm and 80mm respectively, use a wire angle grinder to remove the oxide film on the surface of the base metal to be welded, and use 400# sandpaper to polish the edge of the titanium alloy to be welded and the butt end surface , use alcohol to wipe the base metal to be welded and dry it for later use.

[0034] Step 2: Use cold spray technology to spray high-purity copper powder (99.99% purity) on the part of the titanium alloy to be welded. The particle size of the copper powder is 20 μm. The cold spraying process parameters are: acceleration air pressure 2.5MPa, powder feeding air pressure 3MPa, powder feeding volume 25g / min, helium heating temperature 400-450°C, spraying distance 15mm. According to the test, the thickness of the copper coating under this process is about 0.5mm.

[0035] Step 3: Assembly positioning. Put the cold sprayed titanium alloy and stai...

Embodiment 2

[0040] Step 1: Clean up the base metal to be welded in the same manner as in Example 1.

[0041] Step 2: Use cold spray technology to spray high-purity copper powder (99.99% purity) on the part of the titanium alloy to be welded. The particle size of the copper powder is 20 μm. The cold spraying process parameters are: acceleration gas pressure 2.5MPa, powder feeding gas pressure 3MPa, powder feeding volume 15g / mi, helium heating temperature 400-450°C, spraying distance 15mm. According to the test, the thickness of the copper coating under this process is about 0.1 mm.

[0042] Step 3: The assembly and positioning method is the same as that in Embodiment 1.

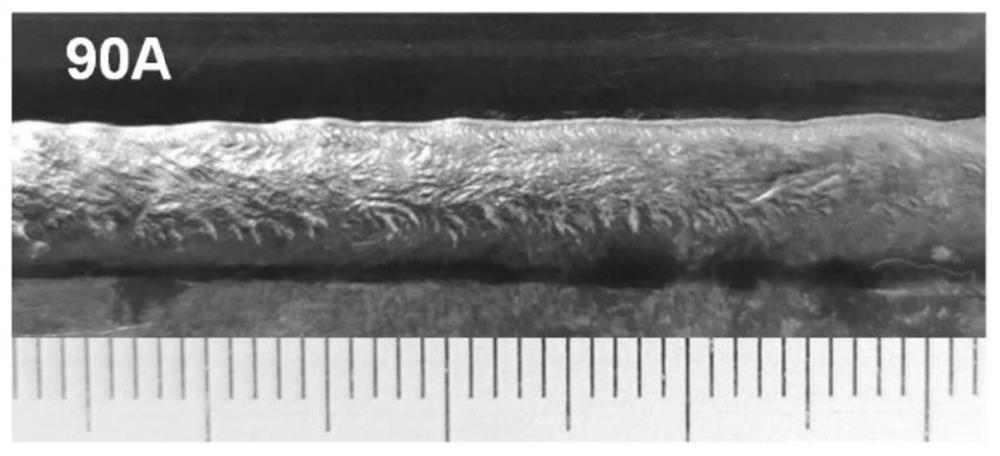

[0043] Step 4: Welding. The welding power source adopts variable polarity tungsten argon arc welding (VPTIG), the welding current is 30A, the welding speed is 120mm / min, the wire feeding speed is 360mm / min, and the shielding gas flow rate is 15L / min.

[0044] Step 5: After the welding is completed, delay the air supply...

Embodiment 3

[0047] Step 1: Clean up the base metal to be welded in the same manner as in Example 1.

[0048] Step 2: Use cold spray technology to spray high-purity copper powder (99.99% purity) on the part of the titanium alloy to be welded. The particle size of the copper powder is 20 μm. The cold spraying process parameters are: acceleration gas pressure 3.5MPa, powder feeding gas pressure 4MPa, powder feeding volume 35g / min, helium heating temperature 400-450°C, spraying distance 15mm. According to the test, the thickness of the copper coating under this process is about 0.3mm.

[0049] Step 3: The assembly and positioning method is the same as that in Embodiment 1.

[0050] Step 4: Welding. The welding power source adopts variable polarity tungsten argon arc welding (VPTIG), the welding current is 50A, the welding speed is 120mm / min, the wire feeding speed is 480mm / min, and the shielding gas flow rate is 15L / min.

[0051] Step 5: After the welding is completed, delay the air supply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com