Welding pipe adjustable vertical roll tool

A vertical roller and tooling technology, applied in welding accessories and other directions, can solve the problems of applied compressive stress, low mechanical properties, poor effect, etc., and achieve the effect of reducing the difficulty of mold adjustment, reducing the scrap rate, and facilitating widespread use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

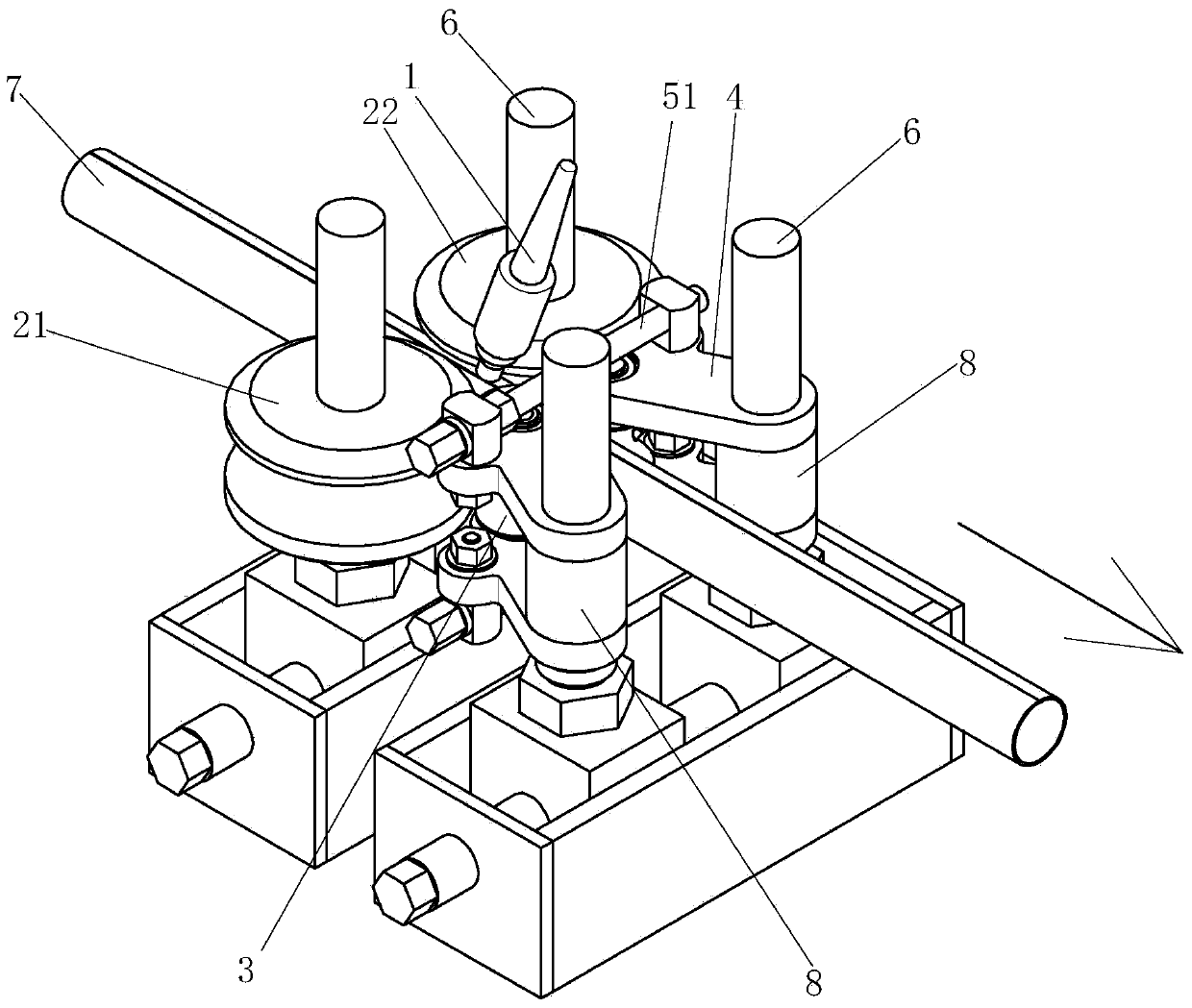

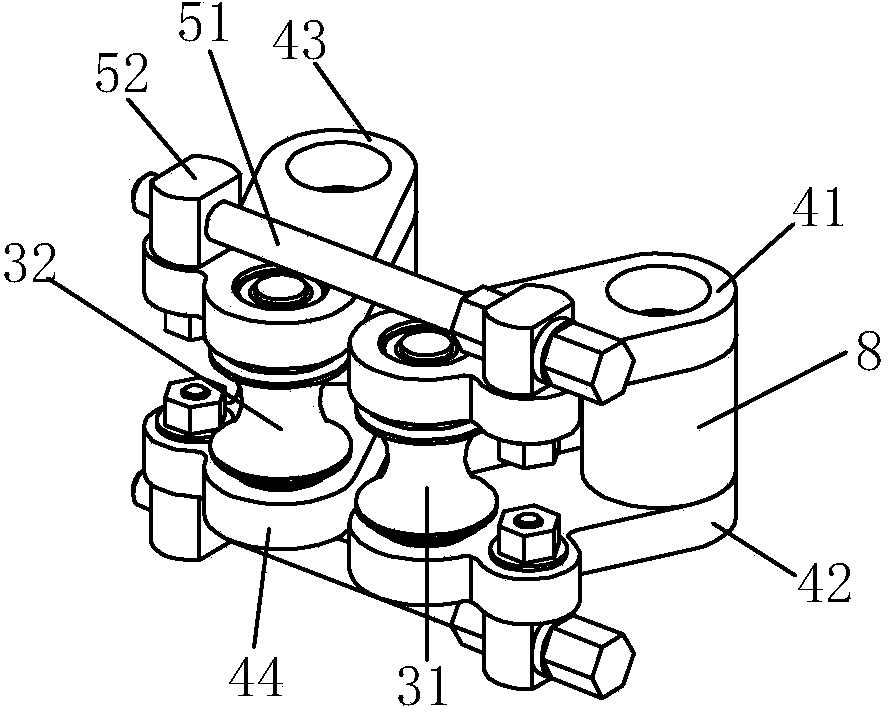

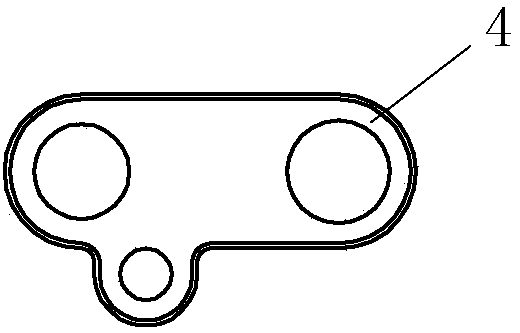

[0019] An adjustable vertical roller tooling for welded pipes, including a welding torch 1, a large vertical roller, a small vertical roller 3, a cantilever 4, a pull rod, a roller shaft I and a roller shaft II, and the large vertical roller includes a large vertical roller I21 and a large vertical roller Roller II22, the large vertical roller I21 and the large vertical roller II22 are respectively installed on the pipe welding machine through the roller shaft 6, the small vertical roller 3 includes the small vertical roller I31 and the small vertical roller II32, and the cantilever 4 includes the cantilever I41, cantilever II42, cantilever III43 and cantilever IV44, the pull rods include pull rod I and pull rod II, one end of the cantilever 4 is provided with a mounting hole for installing the small vertical roller 3, and the other end of the cantilever 4 is provided with a mounting hole for Install the mounting hole of the roller shaft 6, the two ends of the small vertical ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com