Welding method for S32750 super duplex stainless steel welded pipe

A duplex stainless steel and welding method technology, applied in the field of steel pipe welding, can solve the problem that the mechanical properties of welded joints are lower than those of the base metal, and achieve the effect of improving mechanical properties and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] The percentage by weight of the chemical composition of the S32750 super duplex stainless steel of the present embodiment is:

[0021] C: 0.023% Si: 0.55% Mn: 0.95% P: 0.021% S: 0.001% Cr: 25.23% Ni: 7.04% Mo: 4.11% N: 0.2547%, the rest is Fe and unavoidable impurities.

[0022] In this embodiment, steel 3 with a diameter of Φ150 mm and a thickness of 1.2 mm is welded. The material used is S32750 super duplex stainless steel strip, the operation steps are as follows:

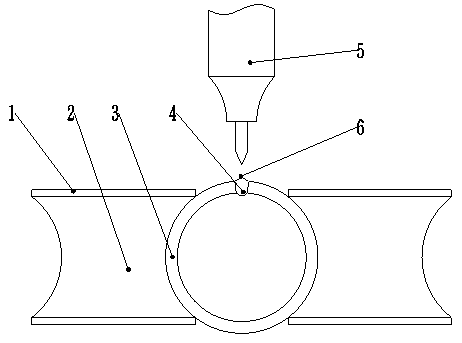

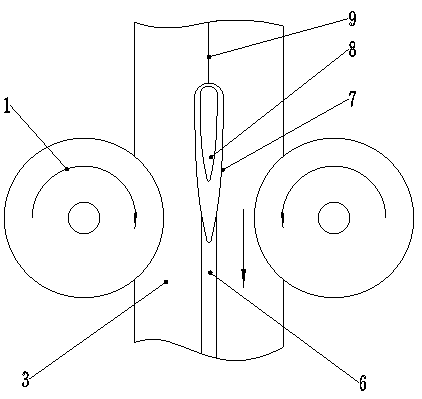

[0023] Ⅰ Install a pair of forming wheels 1 on the argon tungsten arc welding production line. The forming wheel 1 has an arc-shaped forming groove 2. The radius of the forming groove 2 is R75mm. See figure 1 and figure 2 . The forming grooves 2 of the two forming wheels 1 are clamped on both sides of the steel pipe 3; figure 2 Move in the direction of the arrow, that is, move downward, and the steel pipe 3 drives the forming wheel 1 to rotate;

[0024] II welding torch 6 welds the groove 9 to be w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com