Laser-arc hybrid welding system

A composite welding and lighting system technology, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high maintenance cost, special machine only, and non-disassembly, so as to improve the mechanical properties of the weld seam and reduce the welding cost. The effect of cracks and convenient welding adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

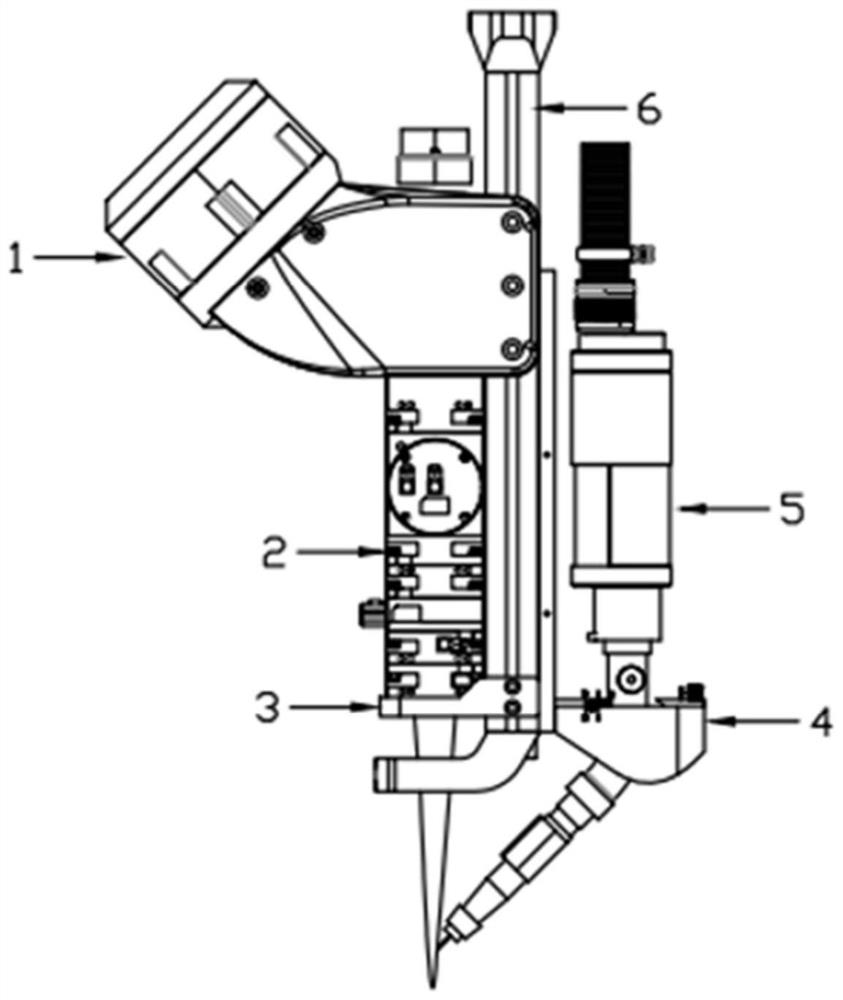

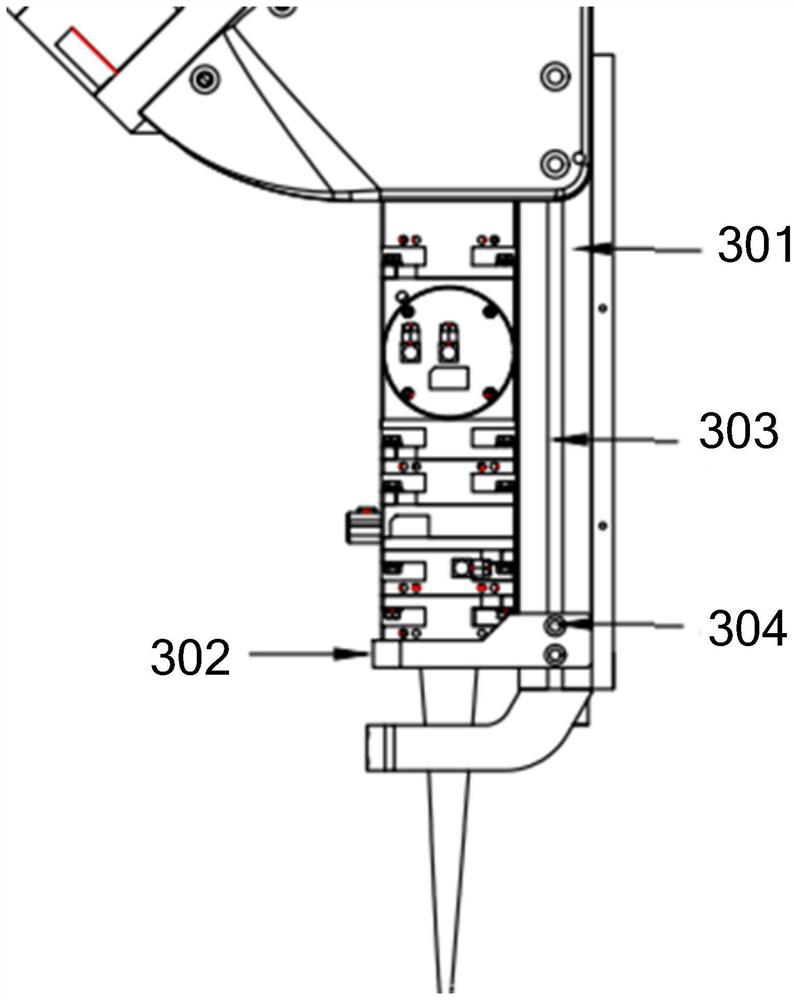

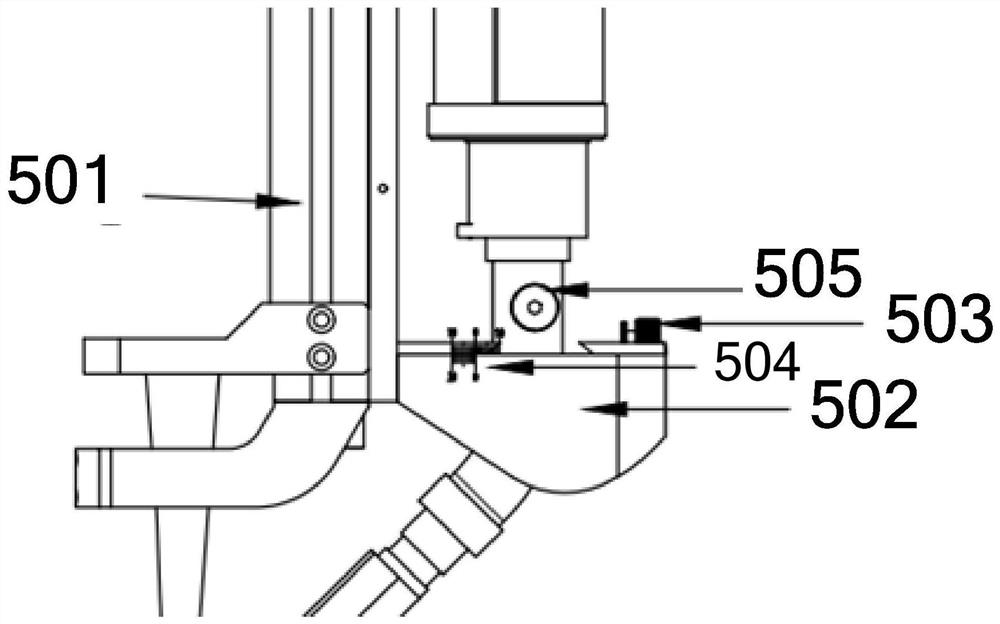

[0052] Such as Figure 1-7 As shown, the present embodiment provides a laser-arc hybrid welding system, including a laser light emitting system, a welding device and a control system. The welding device includes a main frame 6 on which a laser focusing device 2 and a first adjustment mechanism 3 are arranged. , a welding torch 4, a second adjustment mechanism 5 and a movement mechanism connection assembly 1, the laser focusing device 2 is connected and arranged on the first adjustment mechanism 3, and the first adjustment mechanism 3 is connected and arranged on the main frame 6, and the first adjustment mechanism 3 is used for Move the laser focusing device 2 and fix the laser focusing device 2. The movement mechanism connection assembly 1 is connected and arranged on the main frame 6. The movement mechanism connection assembly 1 is used to connect the external executive movement mechanism. The welding torch 4 is connected and arranged on the second adjustment mechanism 5 Abo...

Embodiment 2

[0057] Those skilled in the art can understand this embodiment as a more specific description of Embodiment 1.

[0058] This embodiment provides a hybrid welding device that combines laser-arc heat sources, which combines the respective advantages of laser and arc. The device includes a laser light emitting system, a connecting flange connected to a moving mechanism, a laser focusing device, a fixing and Z-direction adjusting mechanism of the laser focusing device, a welding torch, a fixing and three-dimensional adjusting mechanism of the welding torch, a main frame, and a control system. The fixing and Z-direction adjustment mechanism of the laser focusing device, the fixing and three-dimensional adjustment mechanism of the welding torch are assembled on the connecting mechanism of the moving mechanism through the connecting flange, which is convenient for the overall driving operation of the moving mechanism, and the laser is focused on one point through the laser focusing de...

Embodiment 3

[0064] Those skilled in the art can understand this embodiment as a more specific description of Embodiment 1.

[0065] Such as figure 2 As shown, this embodiment provides a laser-arc hybrid welding system, including a laser light emitting system, a laser focusing device, a welding power supply and a welding torch cable, a fixing of the laser focusing device and a Z-direction adjustment mechanism, a fixing and a three-dimensional adjustment mechanism of the welding torch , the mechanism connected with the motion mechanism and the control system.

[0066] The connecting flange is connected with the moving mechanism such as the robot or machine tool to realize the attitude adjustment and running track control of the whole mechanism; the fixing device of the laser focusing device, the fixing of the welding torch and the three-dimensional adjustment mechanism are assembled on the connecting mechanism of the moving mechanism, which is convenient for the moving mechanism The overa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com