A method for protecting and repairing the furnace skin after the cooling wall of the blast furnace is burned

A repair method and stave technology, which is applied to cooling devices and other directions, can solve problems such as difficult online replacement of staves, potential safety hazards, and harsh conditions, so as to increase the cooling effect, compensate for the thermal shock in the furnace, and reduce weld cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

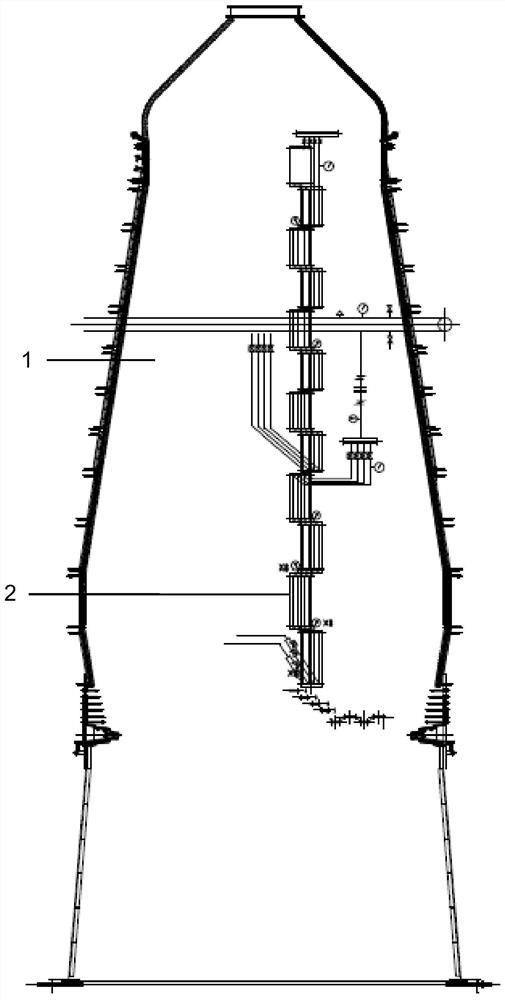

[0027] In order to allow readers to understand the present invention more comprehensively, please refer to figure 1 , figure 2 Shown, the blast furnace related to the present invention is introduced as follows:

[0028] figure 1 It is the blast furnace 1 involved in the present invention. The structure of the blast furnace 1 is from bottom to top, including the furnace hearth, bosh, furnace waist, lower part of the furnace shaft, middle part of the furnace shaft, upper part of the furnace body, and furnace throat. Refractories, cooling equipment, furnace skins. The cooling equipment 2 of the blast furnace is to form staves connected in series with each other.

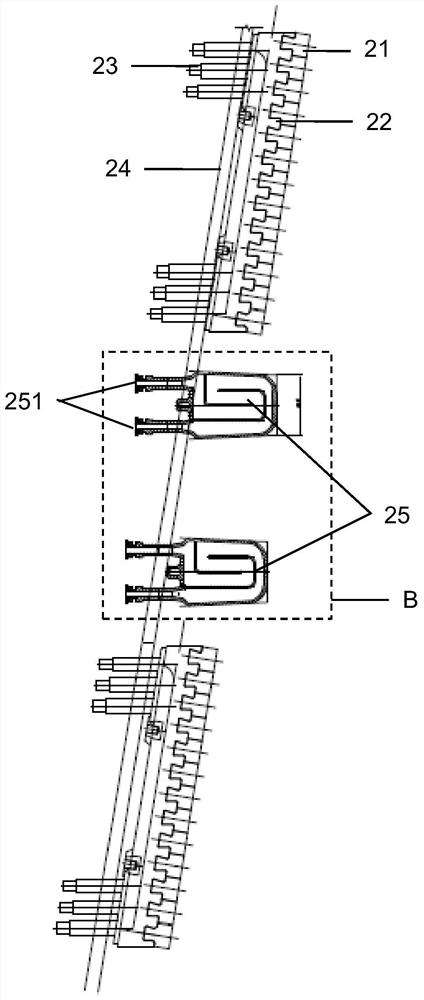

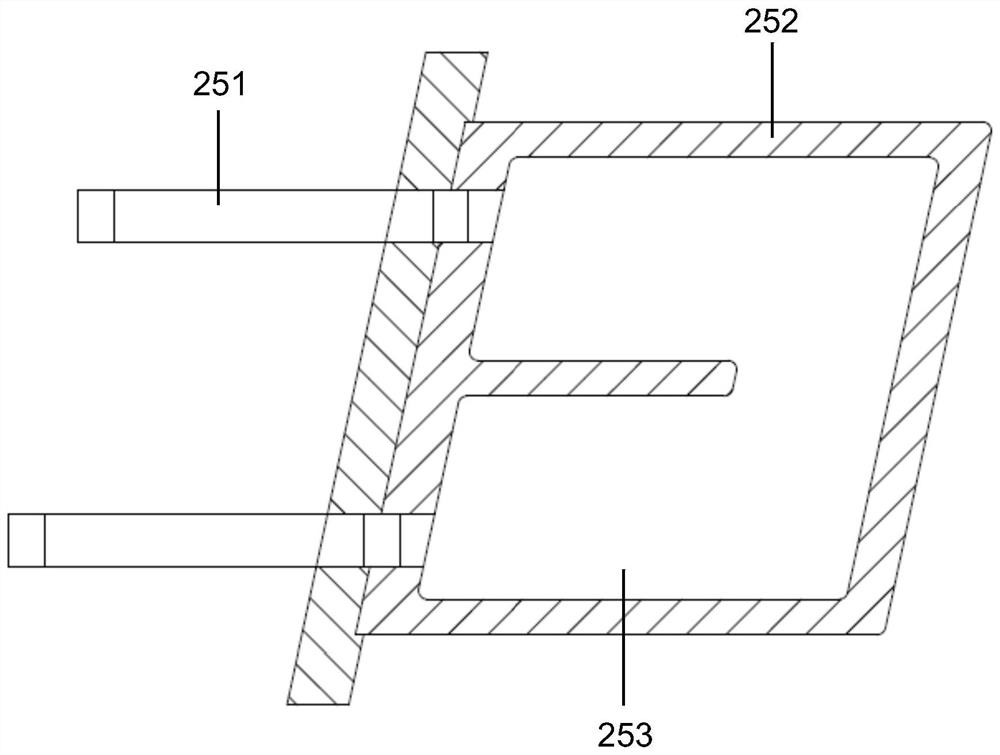

[0029] Please refer again figure 2 As shown, on the blast furnace wall, there is a refractory material 21 close to the furnace cavity. The right side of the refractory material 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com