Welding method for centrifugal casting ductile iron pipe

A welding method and centrifugal casting technology, which are applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of complicated welding process of ductile iron pipes, rising engineering cost, white mouth, etc., and improve the microstructure of weld seam and mechanical properties, improve the toughness of weld deposited metal, and reduce the effect of welding crack tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Material to be welded: arc-shaped plate of ferrite-based nodular cast iron pipe fittings produced by centrifugal casting process, specifications: plate thickness 8mm, arc length 25cm, width 15cm. The chemical composition (mass percentage) of the ductile iron is: C 3.5-3.7%, Si 2.1-2.3%, Mn 0.27%, P 0.061%, S 0.008-0.010%, Mg 0.050%, Fe balance. The mechanical properties are: tensile strength 460MPa, elongation 16%.

[0034] The welding process is as follows:

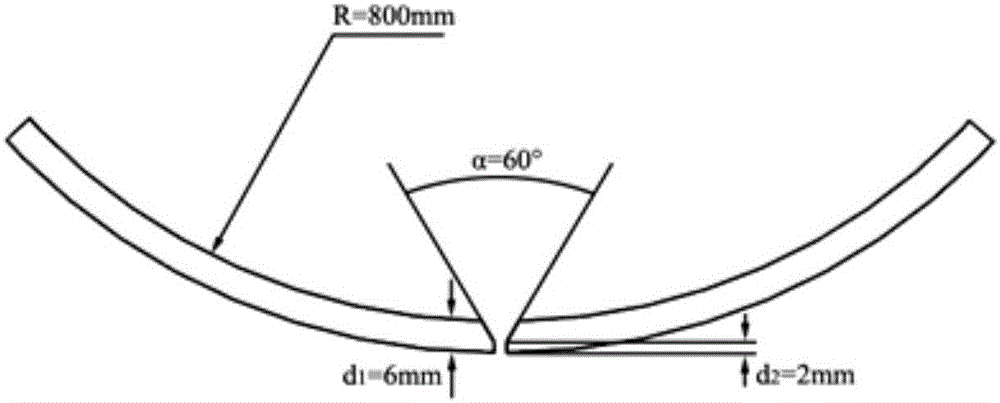

[0035] (1) Butt joints are used for welding, and a straight Y-shaped bevel is opened along the inner side of the 25cm×6mm arc-shaped plate section, with a single-sided bevel angle of 30° and a blunt edge of 2mm. Butt joints in the form of figure 1 shown.

[0036] (2) Preheat with oxygen-acetylene flame before welding, and preheat the groove of the ball iron arc plate to 100°C.

[0037] (3) Using CO 2 For gas shielded welding, the chemical composition of the welding wire is as follows (mass percentage): C 0.08...

Embodiment 2

[0044] Two pairs of ductile iron plates, the specifications are as follows: plate thickness 6mm, width 20cm, arc length 10cm. Open a straight Y-shaped groove along the inner side of the 20cm×6mm section, the groove angle is 30 degrees on one side, and the blunt side is 2mm. CO with diameter φ1.2mm solid welding wire 2 Gas shielded welding.

[0045] The mass percentage of the chemical composition of the welding wire used is as follows: C 0.08%, Mn 1.80%, Si 2.00%, P≤0.025%, S≤0.025%, Ni 3.20%, Cr≤0.015%, Mo≤0.015%, V≤0.03%, Cu ≤0.50%, Fe balance.

[0046] (1) Preheat with oxygen-acetylene flame before welding, and preheat the groove of the ball-milled cast iron plate to 100°C.

[0047] (2) The inner weld uses CO 2 Gas shielded welding is used for continuous welding, and the welding parameters are as follows: welding voltage 20V, welding current 110A, welding wire dry elongation 10mm, welding speed 16cm / min, CO 2 The gas purity is 99.9%, and the gas flow rate is 16L / min.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com