Silicon steel sheet welding active agent and application method thereof

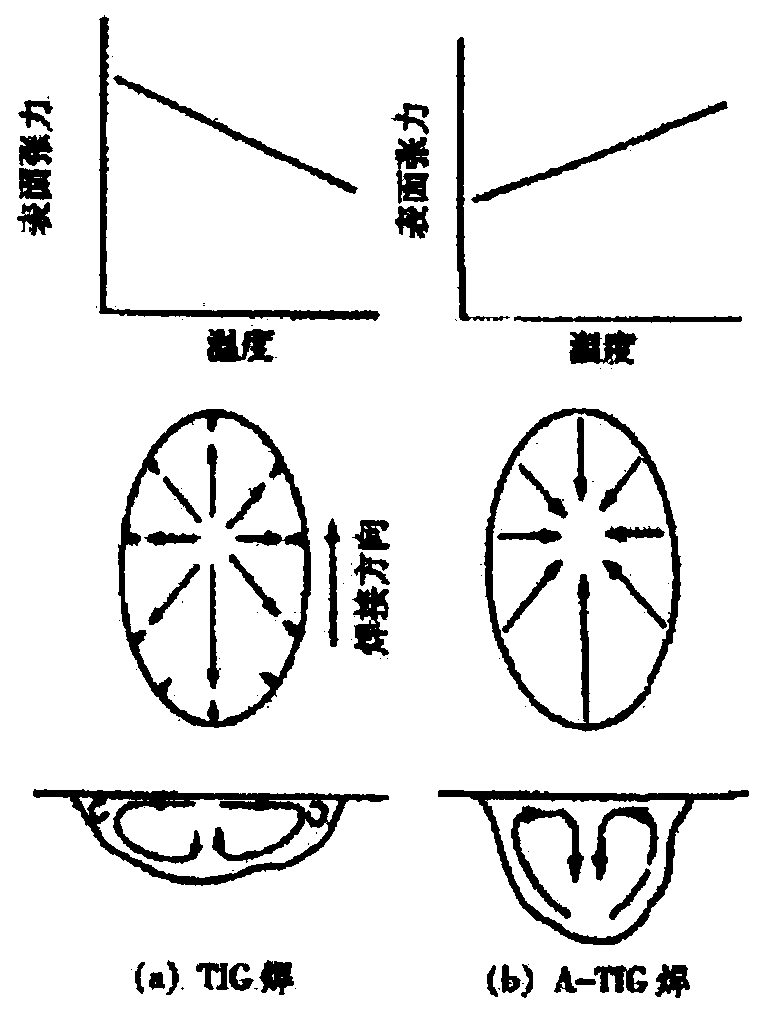

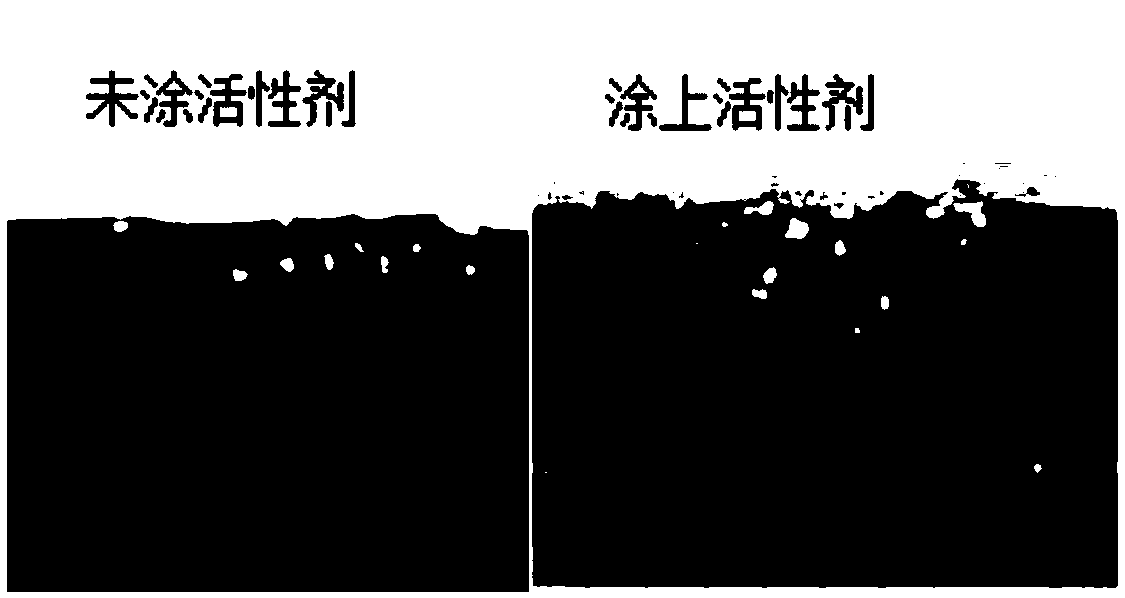

A technology of silicon steel sheets and active agents, applied in welding medium, welding equipment, welding equipment, etc., can solve the problems of easy cracks, small weld penetration, low welding efficiency, etc., to increase welding penetration and weld shape Good, easy-to-clean results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] figure 2 For the preparation process of the active auxiliary agent for silicon steel sheets of the present invention, firstly, the purchased raw materials are powdered according to the formula ratio given by the present invention, then the powder is mixed with a ball milling process and the powder particles are refined, and then the powder is screened with a sieve. to filter.

[0027] Adopting the silicon steel sheet welding active auxiliary agent of the present invention to carry out welding comprises the following steps:

[0028] (1) Prepare the silicon steel sheet welding sample; the size of the silicon steel sheet welding sample is 20cm in outer diameter and 18cm in inner diameter;

[0029] (2) Carry out derusting treatment to the prepared silicon steel sheet welding sample, at first the silicon steel sheet surface is polished with a wire brush, and then the silicon steel sheet surface is polished smooth with sandpaper;

[0030] (3) Coating the silicon steel shee...

Embodiment 1

[0034] Step 1: Prepare a silicon steel sheet welding sample, the size of which is 20cm in outer diameter and 18cm in inner diameter.

[0035] Step 2: Derusting the prepared silicon steel sheet welding sample, firstly grinding the surface of the silicon steel sheet with a wire brush, and then polishing the surface of the silicon steel sheet smooth with sandpaper.

[0036] Step 3, welding and assembling the polished silicon steel sheet welding sample. Apply silicon steel sheet welding activator on the surface of the welding part (the actual composition ratio is NaF: 10%; Fe 2 o 3 : 40%; MnO 2 : 30%; SiO 2 and TiO 2 : balance), the thickness of the active agent coating layer is 0.2-1.0mm.

[0037] Step 4. The silicon steel sheet welding sample is welded by argon tungsten arc welding, and the tip of the tungsten electrode of the welding torch is placed directly above the part to be welded at a distance of 1.5 to 2.5 mm from the coating layer of the active agent. The welding ...

Embodiment 2

[0040] Step 1: Prepare a silicon steel sheet welding sample, the size of which is 20cm in outer diameter and 18cm in inner diameter.

[0041] Step 2: Derusting the prepared silicon steel sheet welding sample, firstly grinding the surface of the silicon steel sheet with a wire brush, and then polishing the surface of the silicon steel sheet smooth with sandpaper.

[0042] Step 3, welding and assembling the polished silicon steel sheet welding sample. Apply silicon steel sheet welding activator on the surface of the welding part (the actual composition ratio is NaF: 20%; Fe 2 o 3 : 30%; MnO 2 : 30%; SiO 2 and TiO2 : balance), the thickness of the active agent coating layer is 0.2-1.0mm.

[0043] Step 4: The silicon steel sheet welding sample is welded by argon tungsten arc welding, and the tip of the tungsten electrode of the welding torch is placed directly above the part to be welded, 1.5-2.5 mm away from the coating layer of the active agent. The welding process paramete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com