Nickel-based alloy welding wire for welding dissimilar steel of nuclear island main equipment and preparation and use method

A nickel-based alloy and main equipment technology, applied in welding medium, welding equipment, metal processing equipment, etc., can solve the problems of welding cracks in deposited metal and lack of welding consumables, and achieve high tensile strength and good sensitivity to cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments.

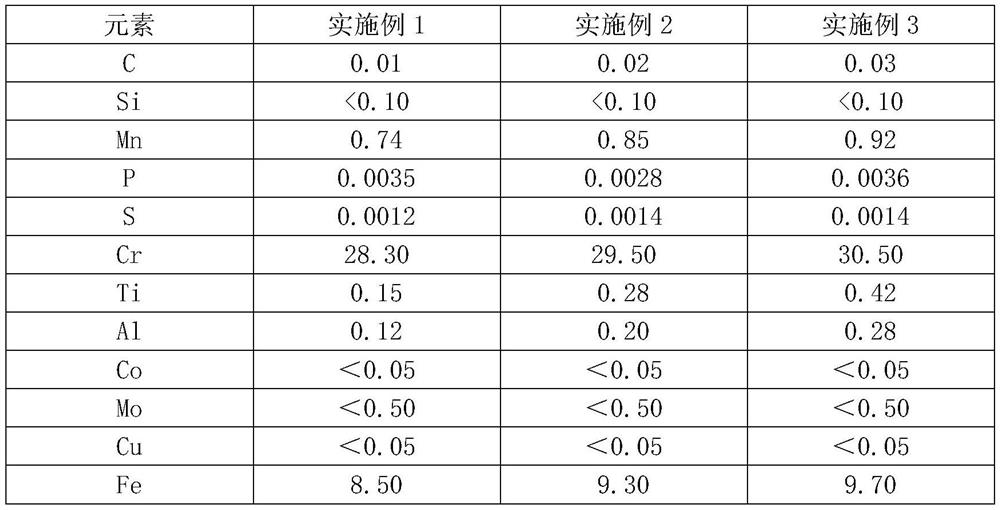

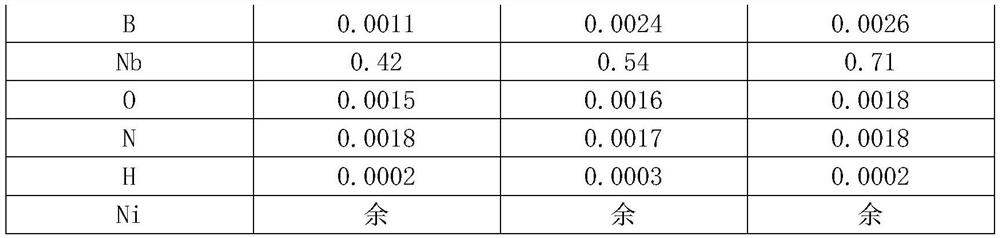

[0020] According to the composition range proposed by the present invention, the composition of the 690 nickel-based alloy welding wire manufactured by processes such as smelting, forging, hot rolling and cold drawing is shown in Table 1. The diameter of the welding wire is φ2.0mm, and the method of non-melting pole manual argon arc welding is adopted The properties of the deposited metal were tested, and the corresponding properties are shown in Table 2.

[0021] Table 1 Chemical composition wt.% of the welding wire of the embodiment

[0022]

[0023]

[0024] The performance test of the deposited metal in the embodiment of table 2

[0025]

[0026] The nickel-based alloy system adopted in the present invention not only has higher tensile strength of deposited metal, but also has better strength and toughness against crack sensitivity. The welding wire of the inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com