Non-preheating welding method of 750MPa-grade high-strength steel medium-thickness plate for hydraulic support

A hydraulic support and welding method technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of poor welding stability, poor welding restraint, impractical application, etc., achieve low tensile strength, reduce welding cracks, Effect of reducing defects such as welding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

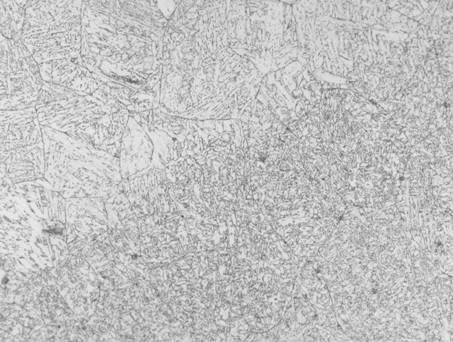

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

[0026] A method for welding without preheating a 750MPa grade high-strength steel plate for a hydraulic support, wherein the 750MPa grade high-strength steel plate refers to a low-carbon, thermomechanically rolled low-alloy high-strength steel plate with a thickness of 20-50 mm, Include the following steps:

[0027] (1) Assemble the parts into hydraulic support structural components, control the depth tolerance of the groove weld to be no more than 2mm, the angle tolerance of the groove weld to be no more than 2°, and the assembly gap of the fillet weld to be no more than 2mm;

[0028] (2) Carry out manual spot welding on each weld seam of the assembled hydraulic support structural components, using ER50-6 φ1.2mm solid core welding wire, using 80% Ar and 20% CO 2 Mixed gas protection, welding parameters: welding current 260-280A, arc vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com