Chip gold wire detector

A detection machine, gold wire technology, applied in conveyor objects, semiconductor/solid-state device testing/measurement, electrical components, etc., can solve the problems of low degree of automation and low detection efficiency, and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

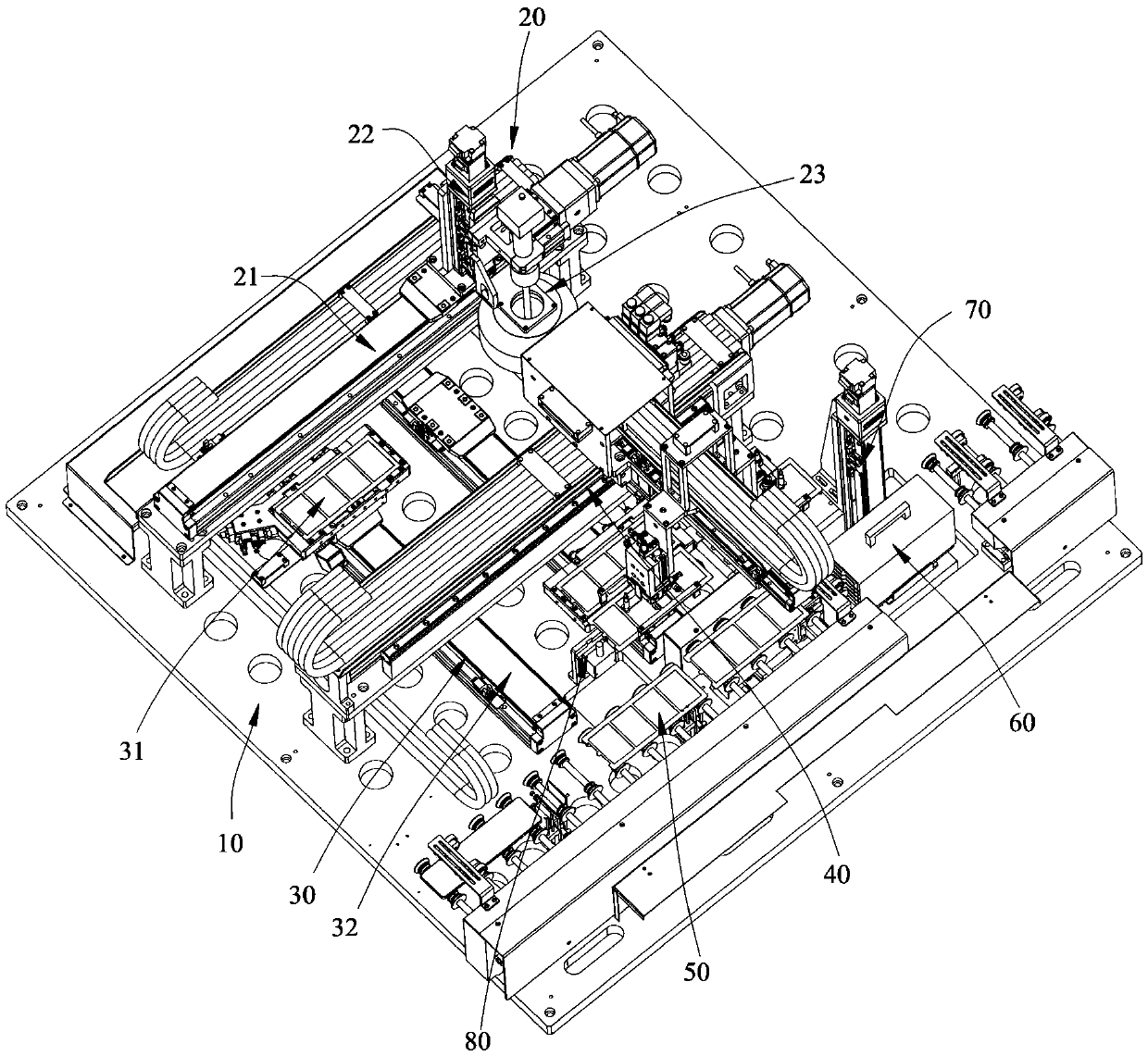

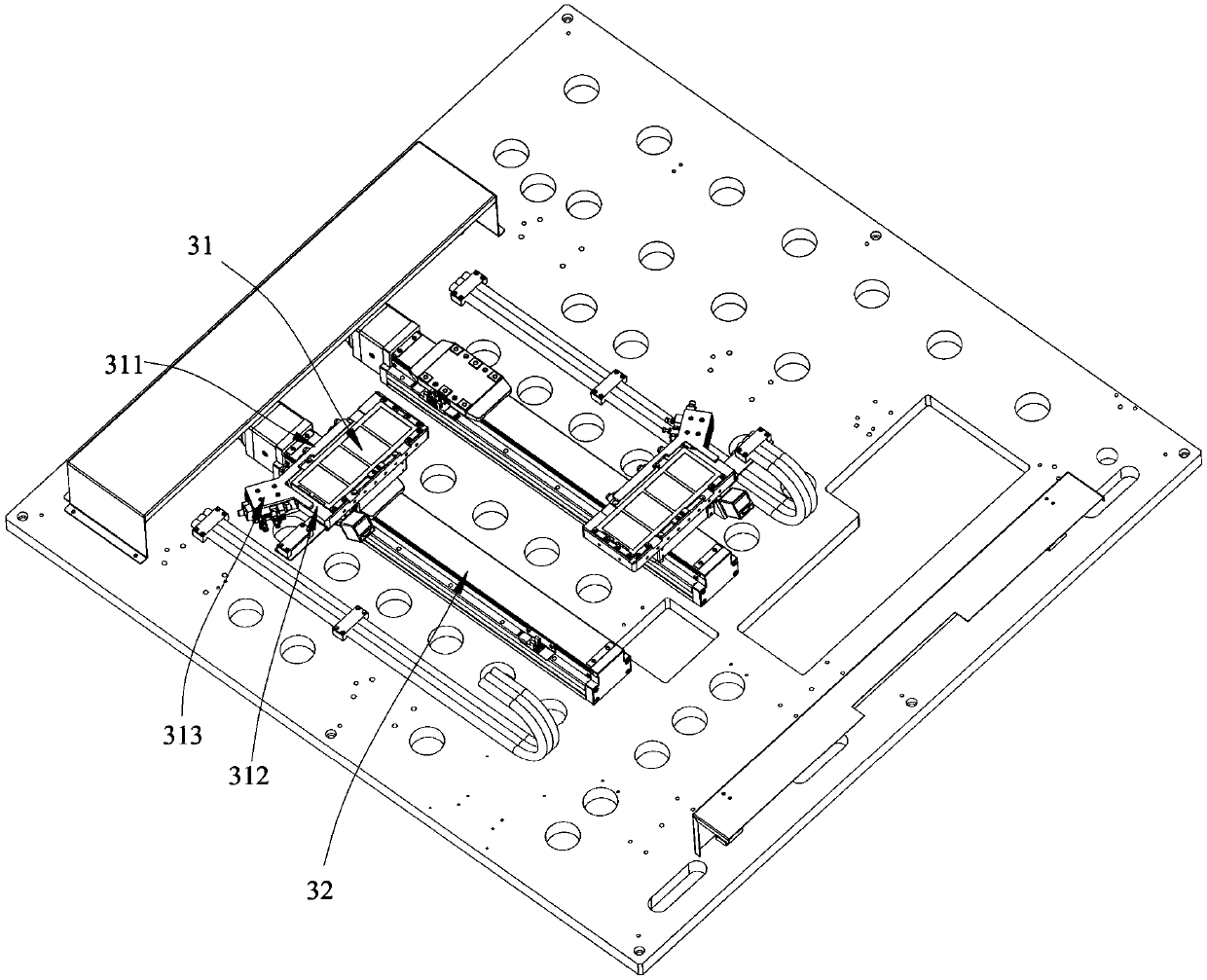

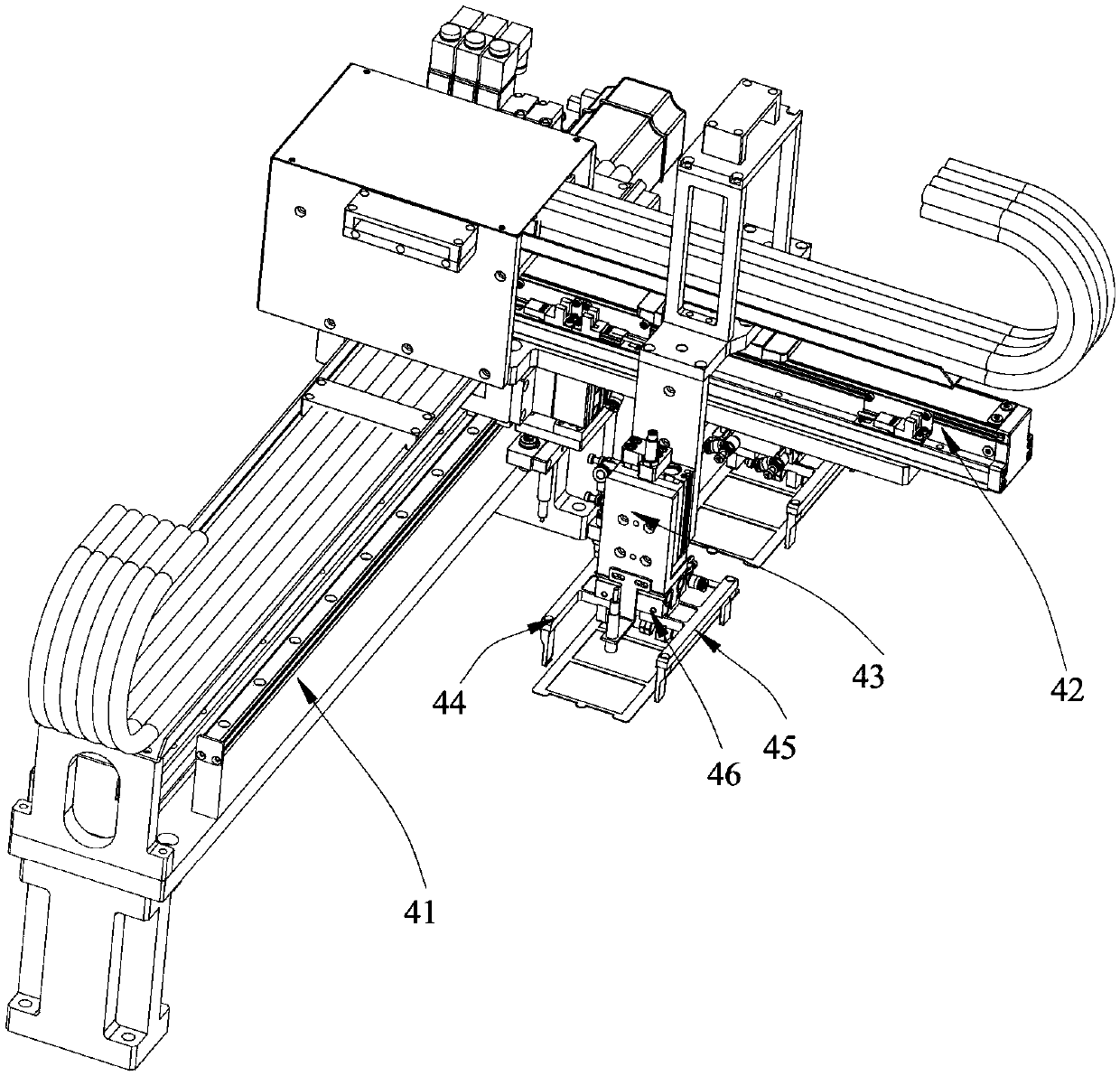

[0027] Such as Figure 1-5 A chip gold wire detection machine shown includes a body 10, a detection mechanism 20, a workpiece carrier mechanism 30, and a workpiece handling mechanism 40, and the detection mechanism 20, the workpiece carrier mechanism 30, and the workpiece handling mechanism 40 are all installed on the body 10 .

[0028] The detection mechanism 20 includes a mounting beam, a detection camera 23 , a first driving assembly 21 and a second driving assembly 22 , the mounting beam is fixed on the body 10 , and the mounting beam extends along the width direction of the body 10 . The detection camera 23 is installed on the installation beam, driven by the first drive assembly 21, the detection camera 23 moves along the extension direction of the installation beam; driven by the second drive assembly 22, the detection camera 23 moves along the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap