Potato slicing mechanism applied to potato planter

A planter, potato technology, applied in the direction of application, rhizome seed cutting machine, seed and rhizome treatment, etc., can solve the problem of missing seeds, and achieve the effect of eliminating the phenomenon of missing seeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

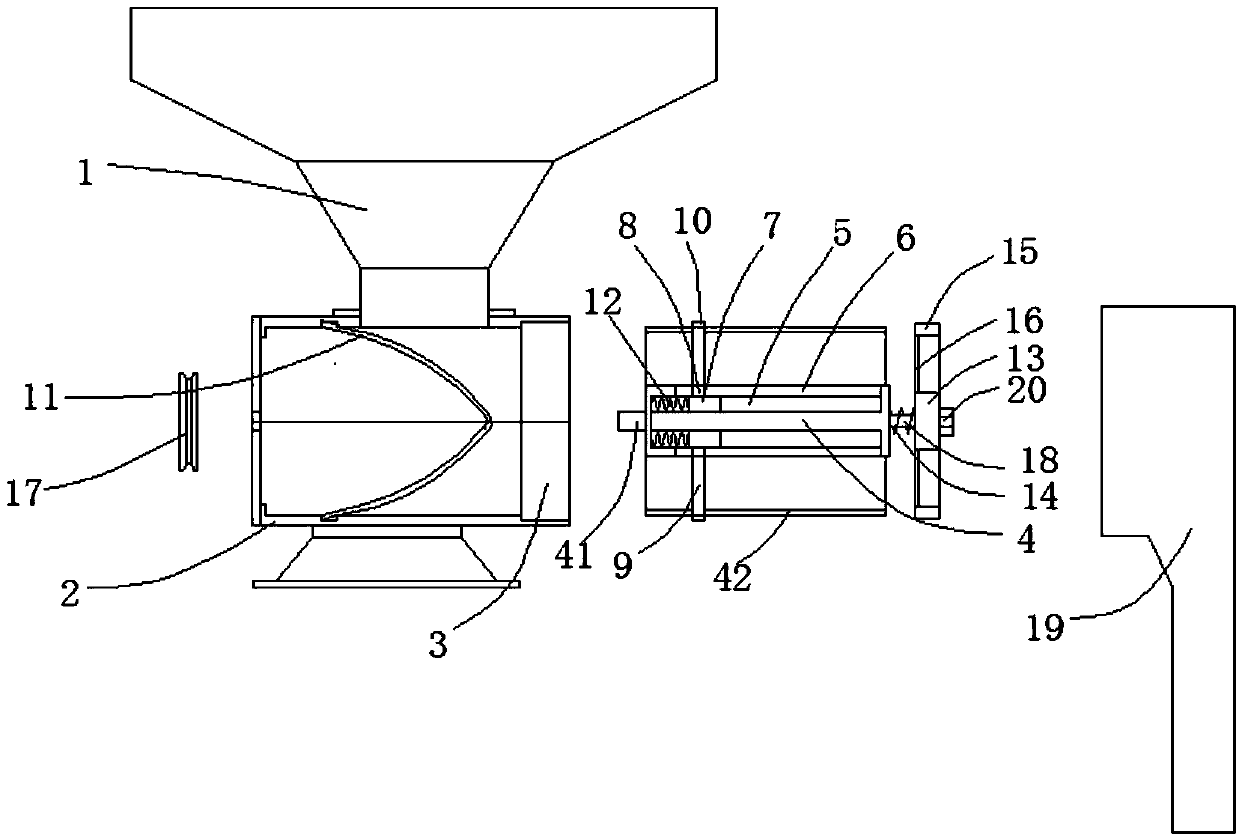

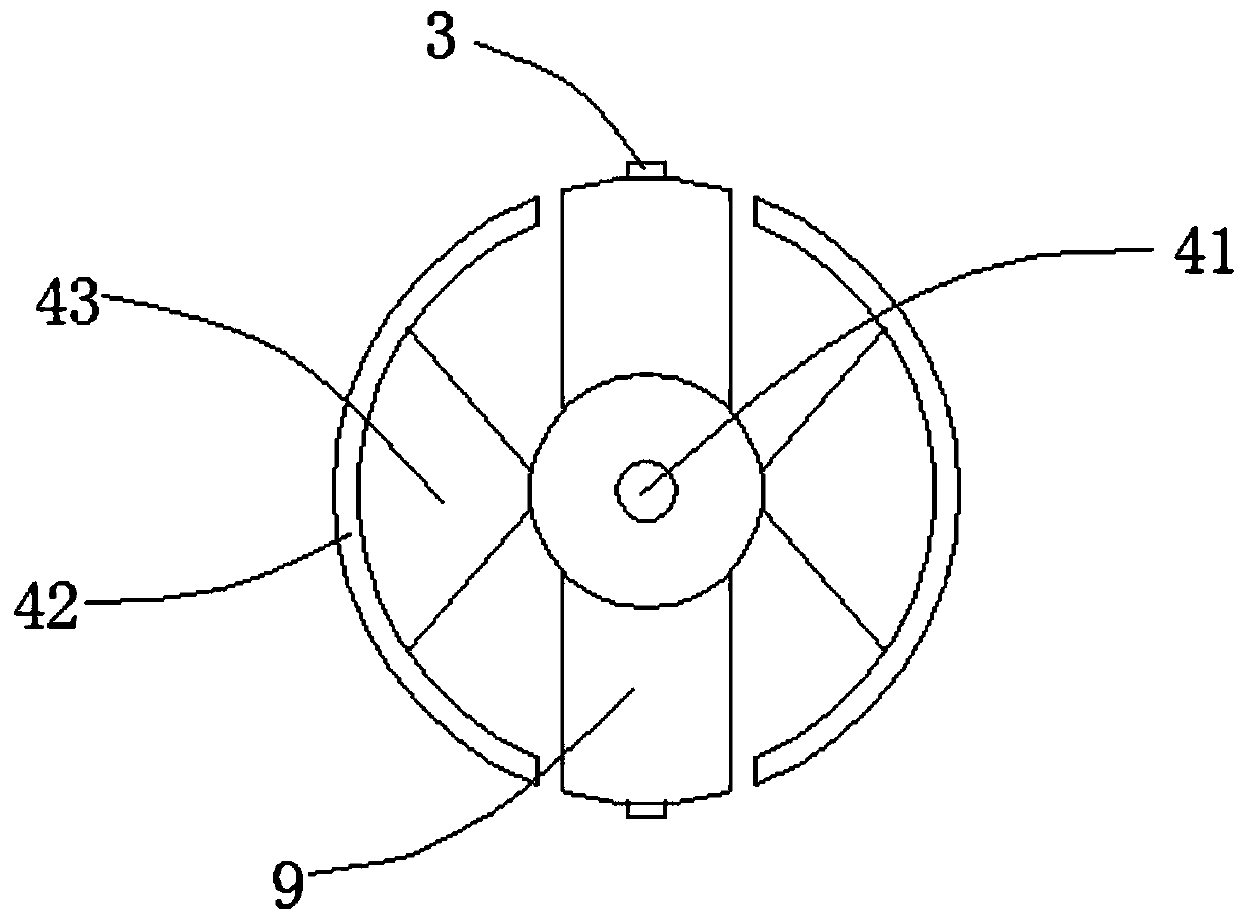

[0015] see Figure 1-2 , the present embodiment includes a casing 2, the upper top surface of the casing 2 is installed with a hopper 1 communicating with the inside, the casing 2 is a hollow cylindrical structure as a whole, and one end of the casing 2 is provided with a discharge port 3. The inside of the casing 2 is provided with a drive shaft 4 that is concentric with it, and the two sides of the drive shaft 4 are axially provided with guide chute 5, and the outer surface of the guide chute 5 is provided with a positioning slide Groove 6, the described guide chute 5 is provided with a guide slider 7 that is slidably matched with its clearance, and one side of the guide slider 7 extends outward a positioning slider 8 that can be slidably matched with the positioning chute 6, The end of the positioning slider 8 is fixed with a pressure plate 9 , and the end of the pressure plate 9 extends upwards out of the positioning column 10 . Groove 11, the arc-shaped groove 11 has a V...

Embodiment 2

[0021] First put all the seed potatoes into the hopper 1, the seed potatoes will naturally fall into the casing 2, then start the motor that cooperates with the belt drive of the pulley 17, and the drive shaft 4 will pass through and locate during the rotation process. The arc-shaped groove 11 of the column 10 slidingly fits the gap to drive the pressure plate 9 to rotate and move in the direction of the discharge port 3, and at the same time the baffle plate 42 starts to close the open end of the hopper 1 until the pressure plate 9 pushes the seed potatoes to pass through the knife holder rod 16 Just cut it;

[0022] When the cutting size of the seed potato needs to be adjusted, the purpose of adjusting the cutting size of the seed potato can be realized by only loosening the nut 20, rotating the positioning ring 15, and adjusting the straight-line distance between the knife rest bar 16 and the edge of the end of the drive shaft 4. Simultaneously, the cut potato pieces direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com