Pedal type loach size separation machine

A separator and foot-operated technology, applied in the field of separators, can solve the problems of low work efficiency, affecting work, trouble, etc., and achieve the effects of good vibration effect, convenient collection and processing, and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

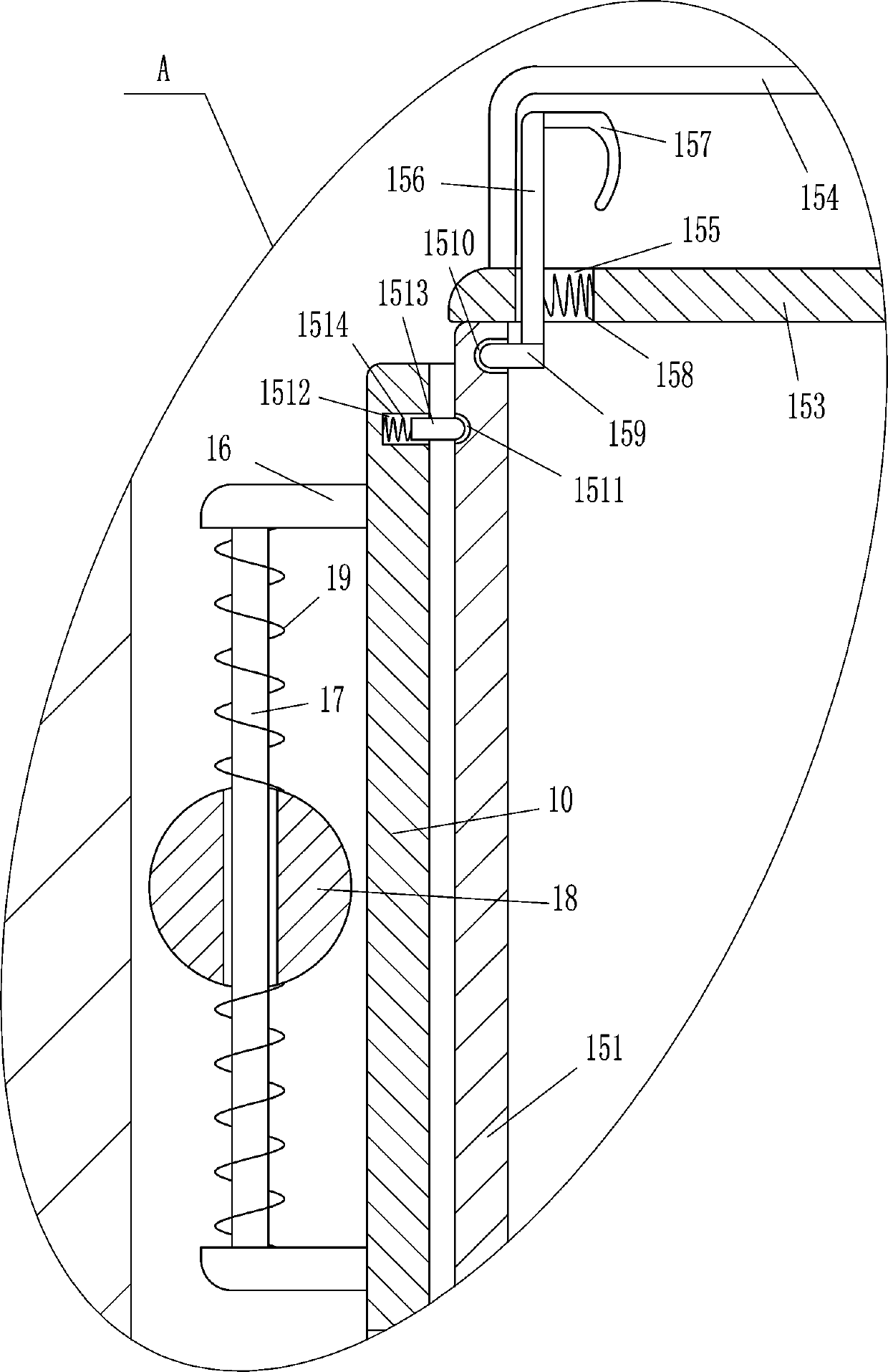

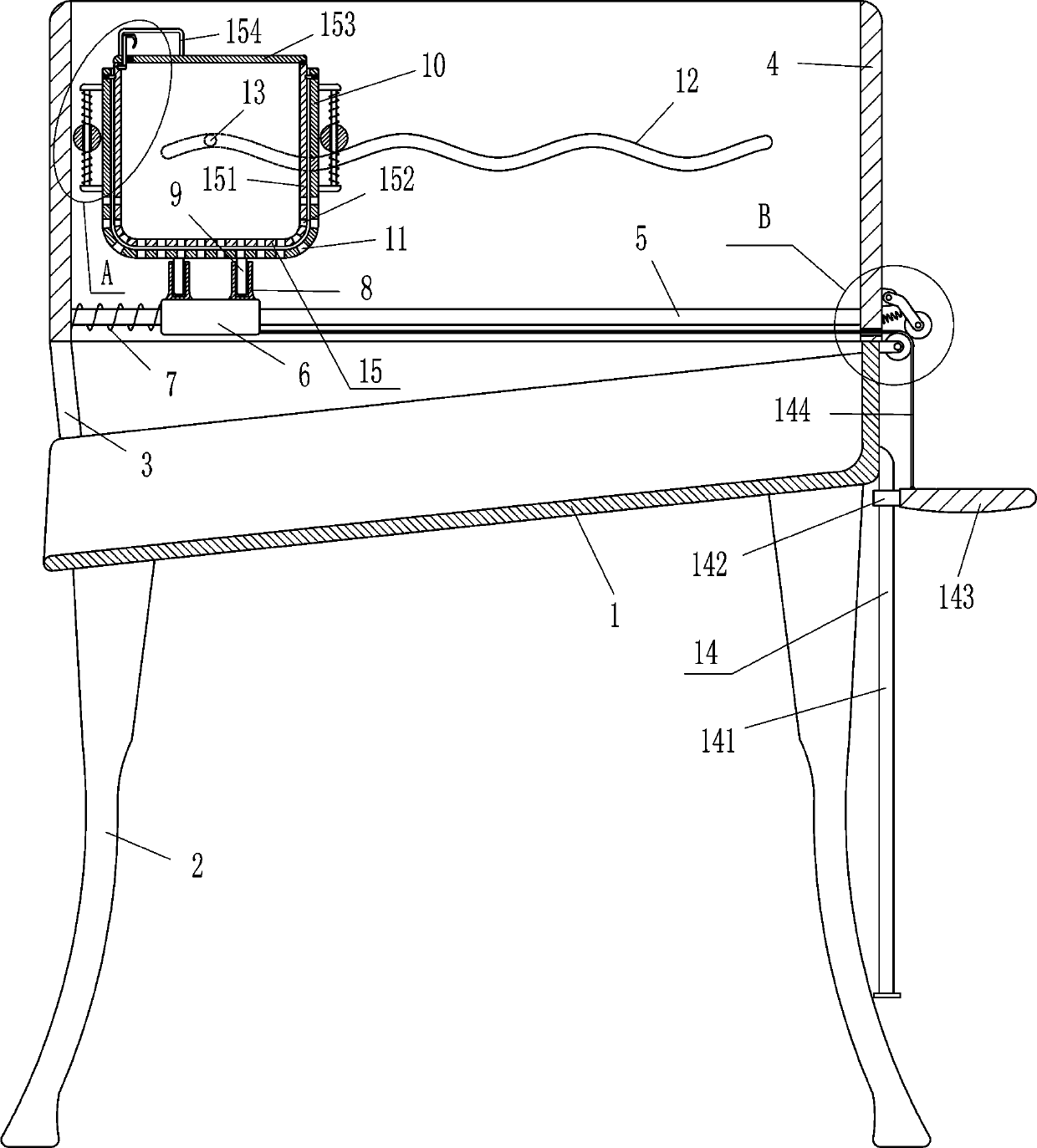

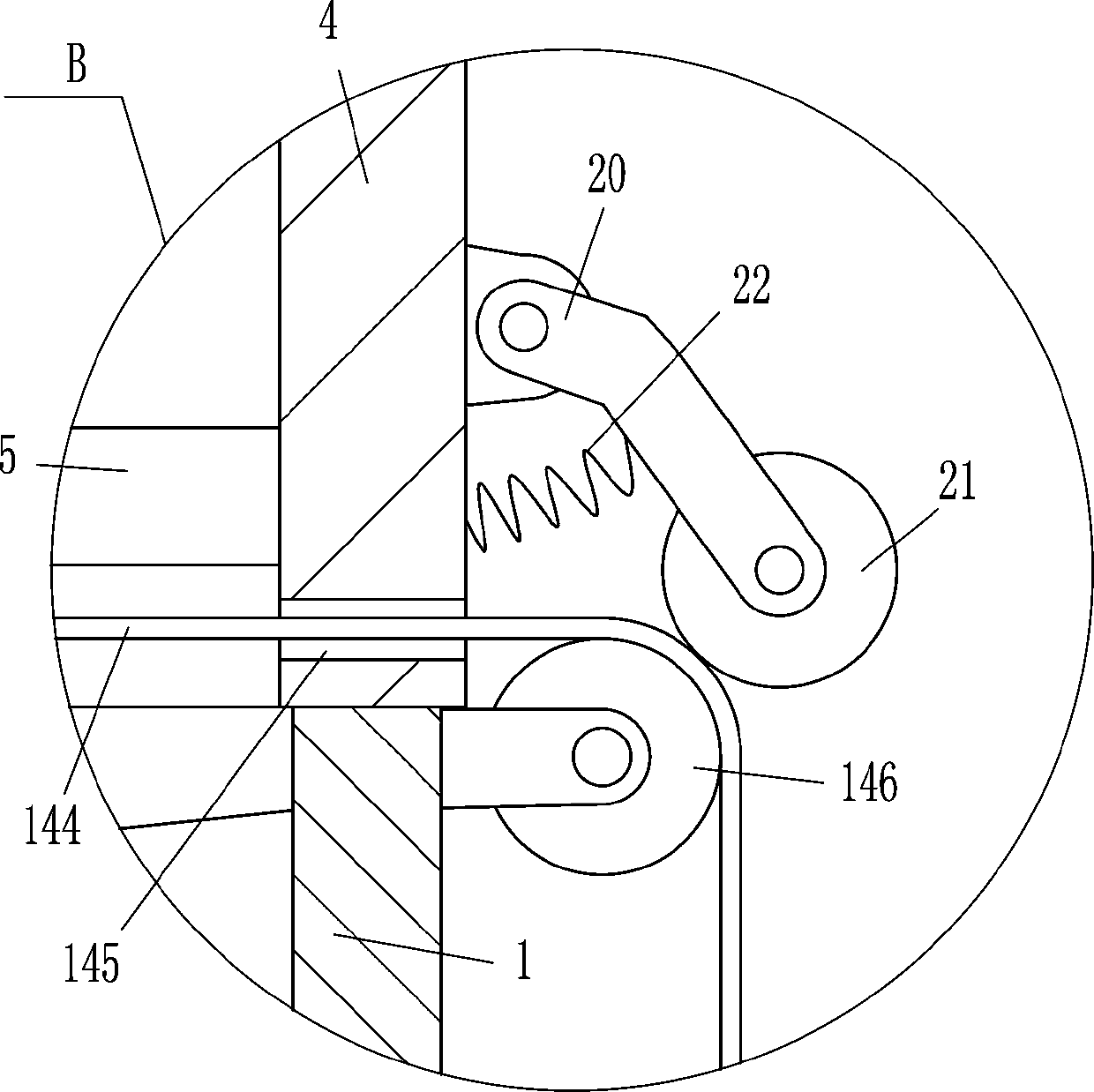

[0016] A foot-operated loach size separator, such as Figure 1-3 As shown, it includes an inclined frame 1, legs 2, support rod 3, frame body 4, cross bar 5, sliding sleeve 6, first spring 7, sleeve 8, sliding rod 9, screening frame 10, roller 13 and The driving mechanism 14, the outer bottom of the inclined frame 1 is symmetrically fixed with outriggers 2 on the left and right sides, the inclined frame 1 is connected with the outriggers 2 through bolt connection, the support rod 3 is installed on the left side of the top of the inclined frame 1, and the support rod Frame 4 is set between the top of 3 and the right side of the top of inclined frame 1. Both support rod 3 and inclined frame 1 are connected to frame 4 through bolt connection. The bottom of frame 4 is open. A crossbar 5 is fixedly connected between the lower parts of the sides, and a reciprocating sliding sleeve 6 is arranged on the crossbar 5. The first spring 7 is set on the crossbar 5, and one end of the first ...

Embodiment 2

[0018] A foot-operated loach size separator, such as Figure 1-3 As shown, it includes an inclined frame 1, legs 2, support rod 3, frame body 4, cross bar 5, sliding sleeve 6, first spring 7, sleeve 8, sliding rod 9, screening frame 10, roller 13 and The driving mechanism 14, the outriggers 2 are symmetrically fixed on the left and right sides of the outer bottom of the inclined frame 1, the support rod 3 is installed on the left side of the top of the inclined frame 1, and a frame is set between the top of the support rod 3 and the right side of the top of the inclined frame 1 4. The bottom of the frame body 4 is open. There is a cross bar 5 fixed between the lower parts of the left and right sides of the frame body 4. A reciprocating sliding sleeve 6 is arranged on the cross bar 5. The first spring 7 is set on the cross bar 5. Above, one end of the first spring 7 is fixedly connected to the left side of the sliding sleeve 6, and the other end of the first spring 7 is fixedly...

Embodiment 3

[0021] A foot-operated loach size separator, such as Figure 1-3 As shown, it includes an inclined frame 1, legs 2, support rod 3, frame body 4, cross bar 5, sliding sleeve 6, first spring 7, sleeve 8, sliding rod 9, screening frame 10, roller 13 and The driving mechanism 14, the outriggers 2 are symmetrically fixed on the left and right sides of the outer bottom of the inclined frame 1, the support rod 3 is installed on the left side of the top of the inclined frame 1, and a frame is set between the top of the support rod 3 and the right side of the top of the inclined frame 1 4. The bottom of the frame body 4 is open. There is a cross bar 5 fixed between the lower parts of the left and right sides of the frame body 4. A reciprocating sliding sleeve 6 is arranged on the cross bar 5. The first spring 7 is set on the cross bar 5. Above, one end of the first spring 7 is fixedly connected to the left side of the sliding sleeve 6, and the other end of the first spring 7 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com