Automatic weighing-blending mechanism of noodle maker

An automatic weighing and production machine technology, applied to the structural components of mixing/kneading machinery, dough mixers, baking, etc., can solve the problems of inaccurate weighing, affecting the quality of noodles, and consuming manpower, and achieve accurate weighing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

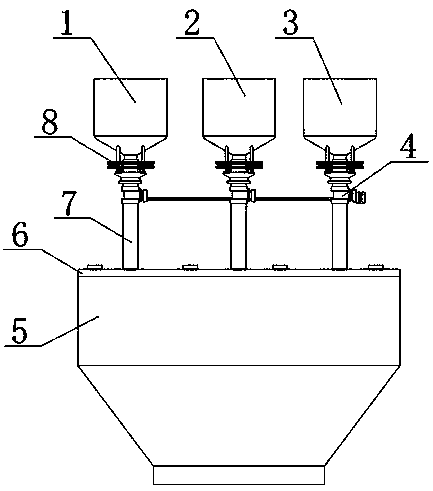

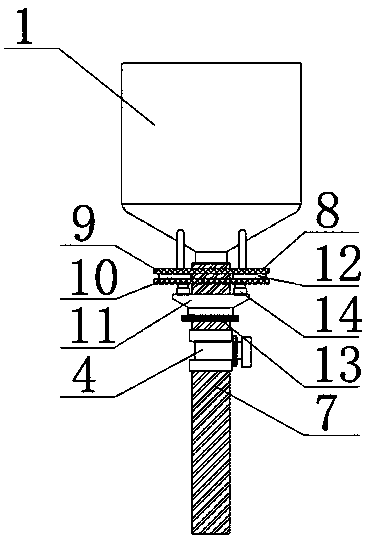

[0019] The present invention as figure 1 , figure 2 Shown:

[0020] An automatic weighing and batching mechanism in a noodle production machine, including a mixing bin 5, the top of which is fixed with a sealing cover 6 by bolts, the sealing cover 6 can prevent dust from entering the inside of the mixing bin 5, and is convenient for installation and feeding Pipe 7, three independent feeding pipes 7 are vertically arranged on the sealing cover 6, and the feeding pipe 7 can be threaded on the sealing cover 6, and the feeding pipe 7 is fixedly provided with a protruding ring 13, and the protruding ring 13 is connected with the feeding tube 7. The material tube 7 is integrally injection molded, and the top of the convex ring 13 is provided with a weighing mechanism 8. The weighing mechanism 8 includes a bracket 11 sleeved on the outer ring of the feeding tube 7. The bracket 11 is located on the top of the convex ring 13, and the convex ring 13 As a single stress point of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com