Glass wiping robot

A glass-cleaning robot and controller technology, applied in robot cleaning machines, cleaning equipment, household appliances, etc., can solve the problems of broken machines, danger, slow speed, etc., and achieve the effect of smooth landing and preventing the machine from falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

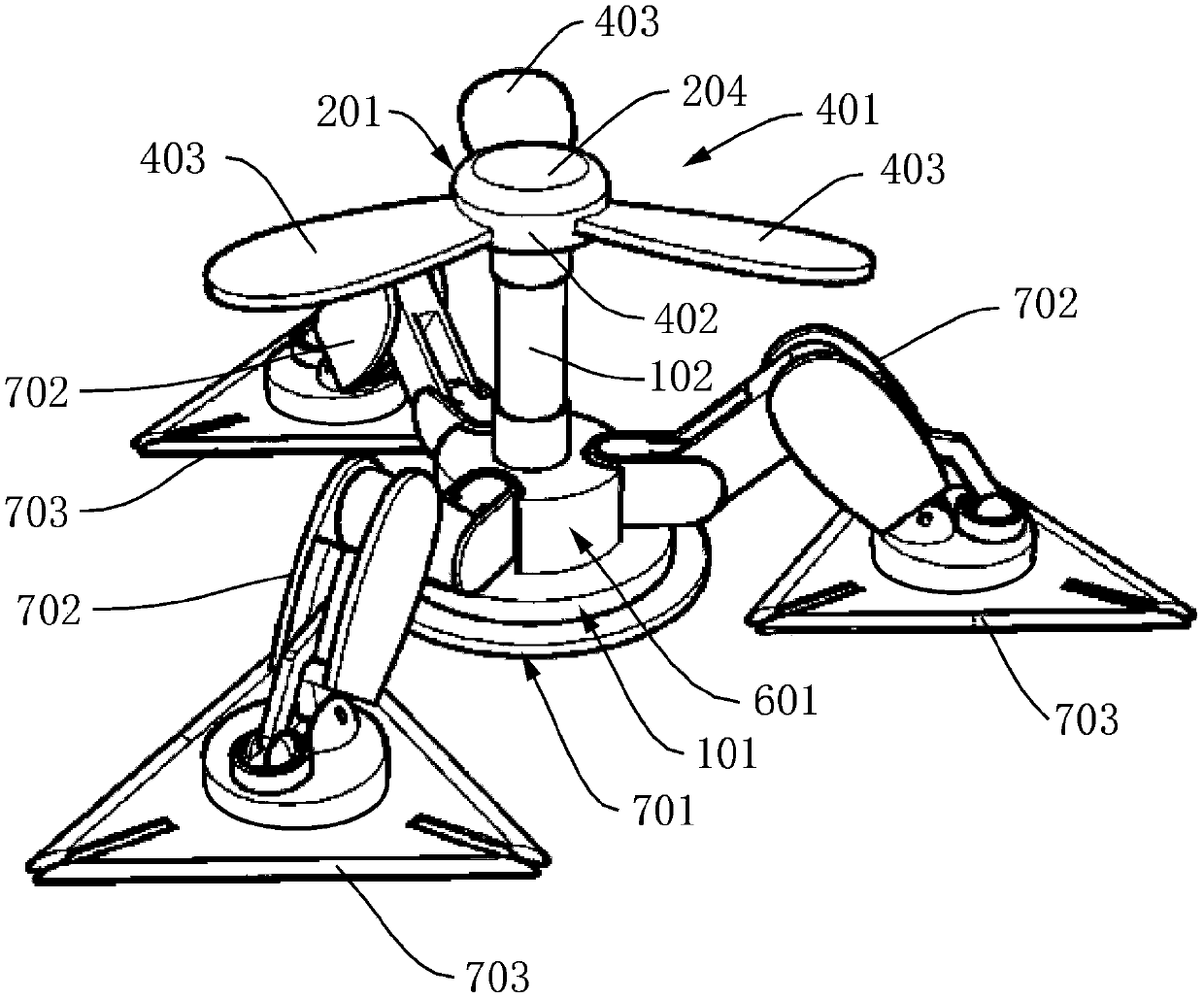

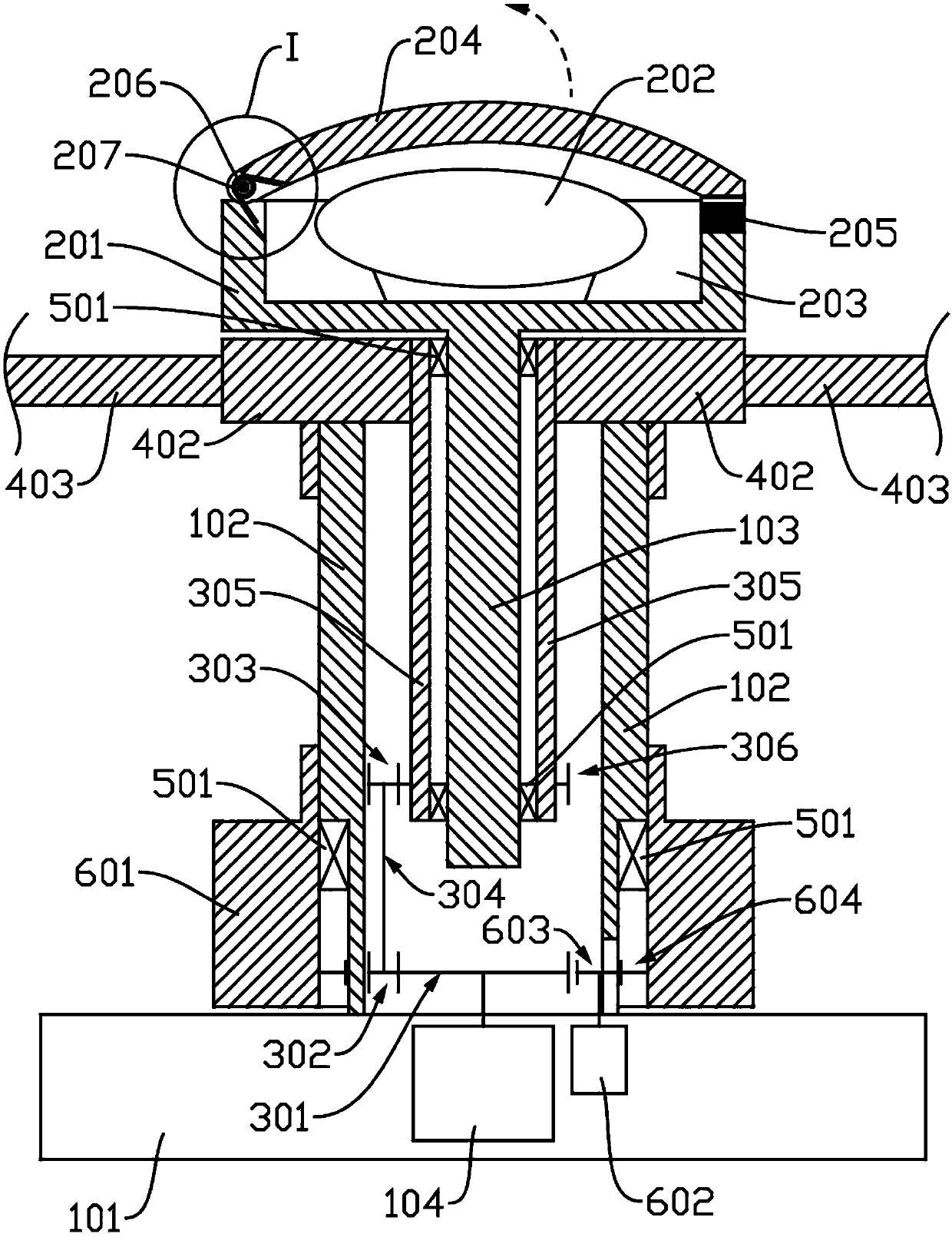

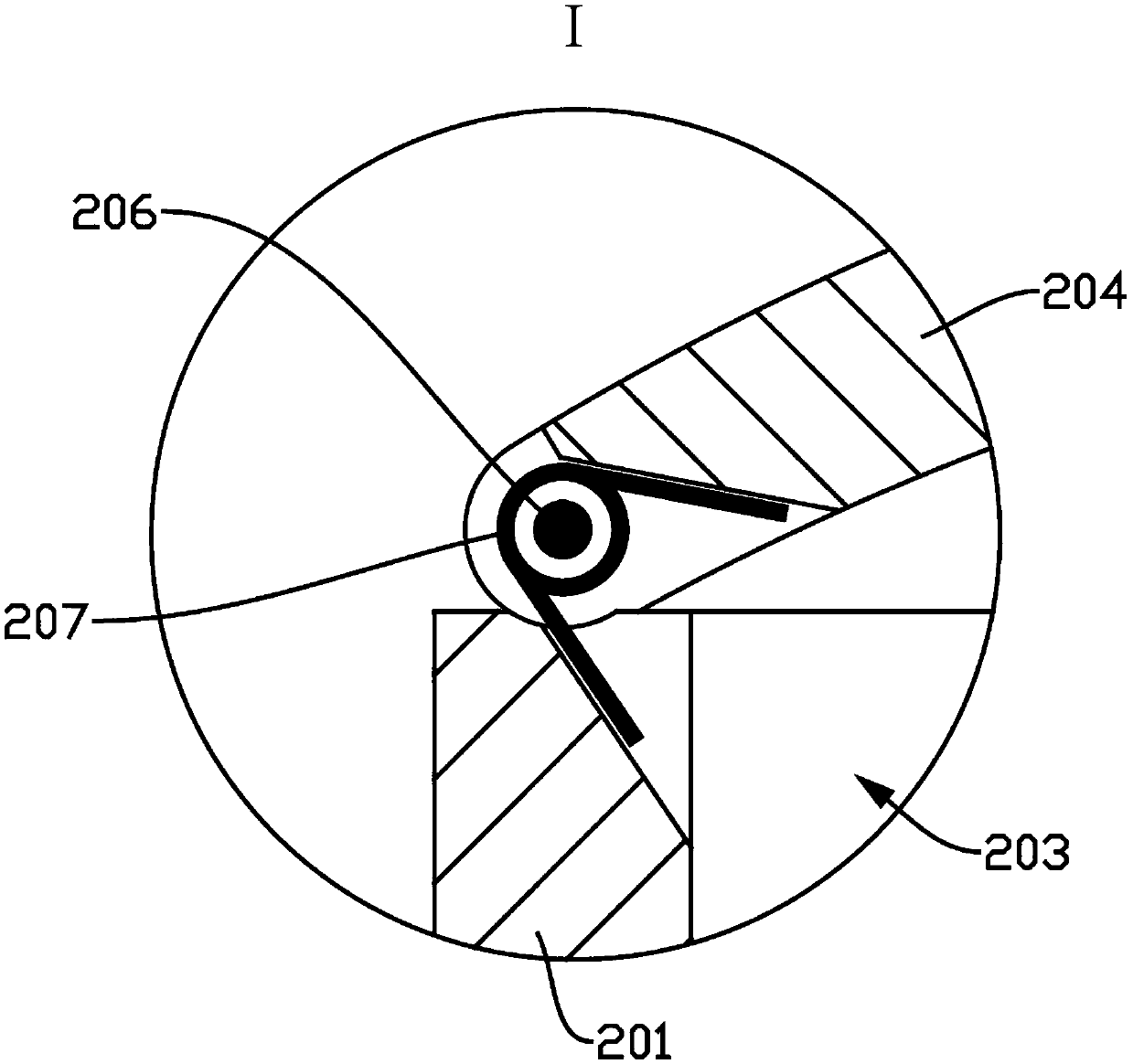

[0031] See figure 1 and figure 2 In this embodiment, a glass-wiping robot is provided, which includes a base 101, a protection chamber 201, a transmission mechanism, and a propeller 401. The base 101 is provided with a cylindrical support tube 102, and the support tube 102 is fixedly arranged inside There is a support column 103. One end of the support column 103 extends out of the support tube 102 and is connected to the protection chamber 201. A parachute 202 is provided in the protection chamber 201; the propeller 401 is sleeved on the support Column 103, the base 101 is provided with a power motor 104, the output shaft of the power motor 104 is connected to the propeller 401 through the transmission mechanism, and the power motor 104 is used to drive the propeller 401 relative to the base 101 and The protection chamber 201 rotates, the propeller 401 is used to carry the base 101 for take-off or landing, and the parachute 202 is used for deceleration and buffering;

[0032] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com