Positioning method of printed circuit board machining

A positioning method and printed circuit technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of re-drilling of positioning holes, drilling of positioning holes, and scrapping of positioning boards, etc., to prevent collisions, save positioning boards, and save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

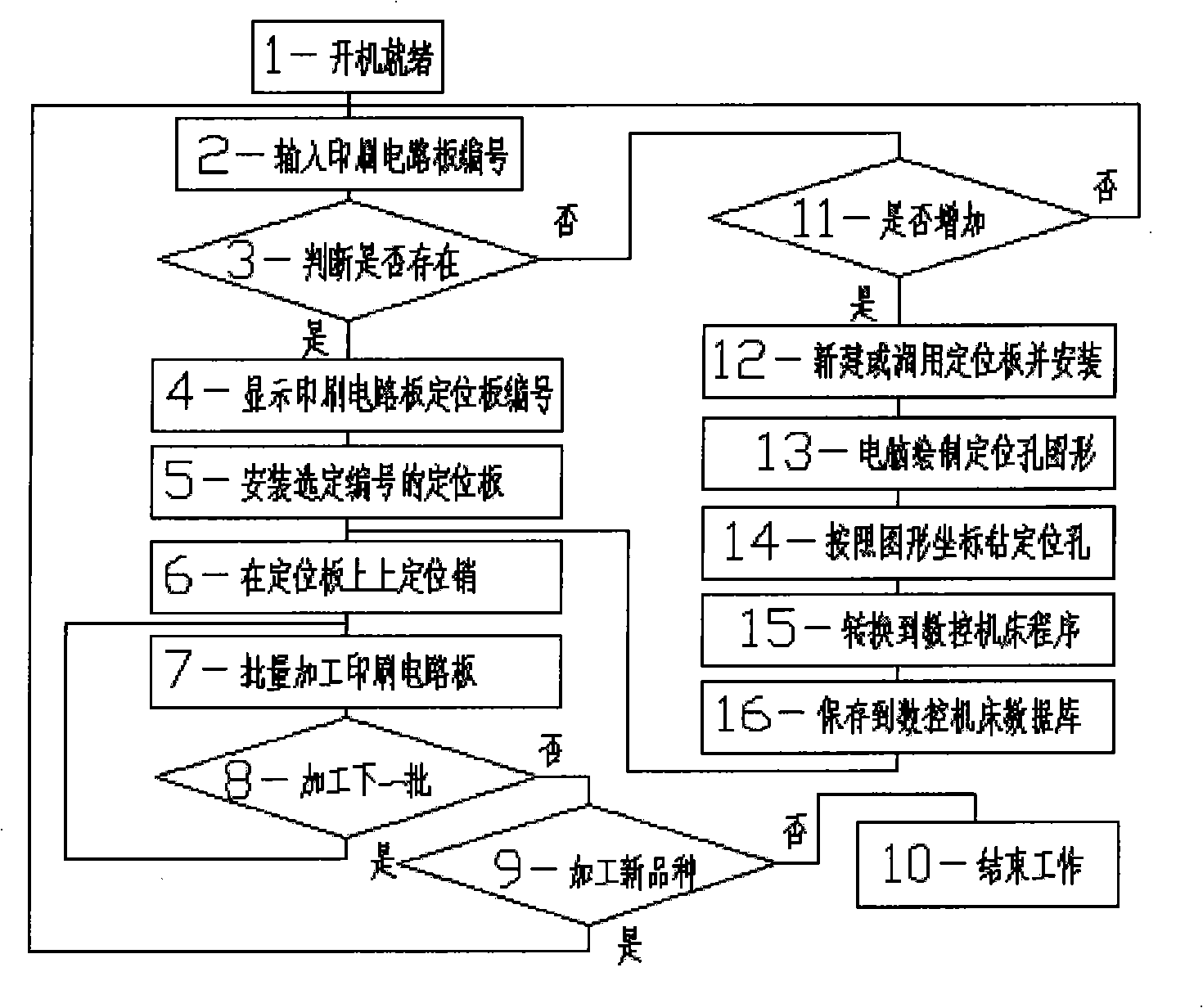

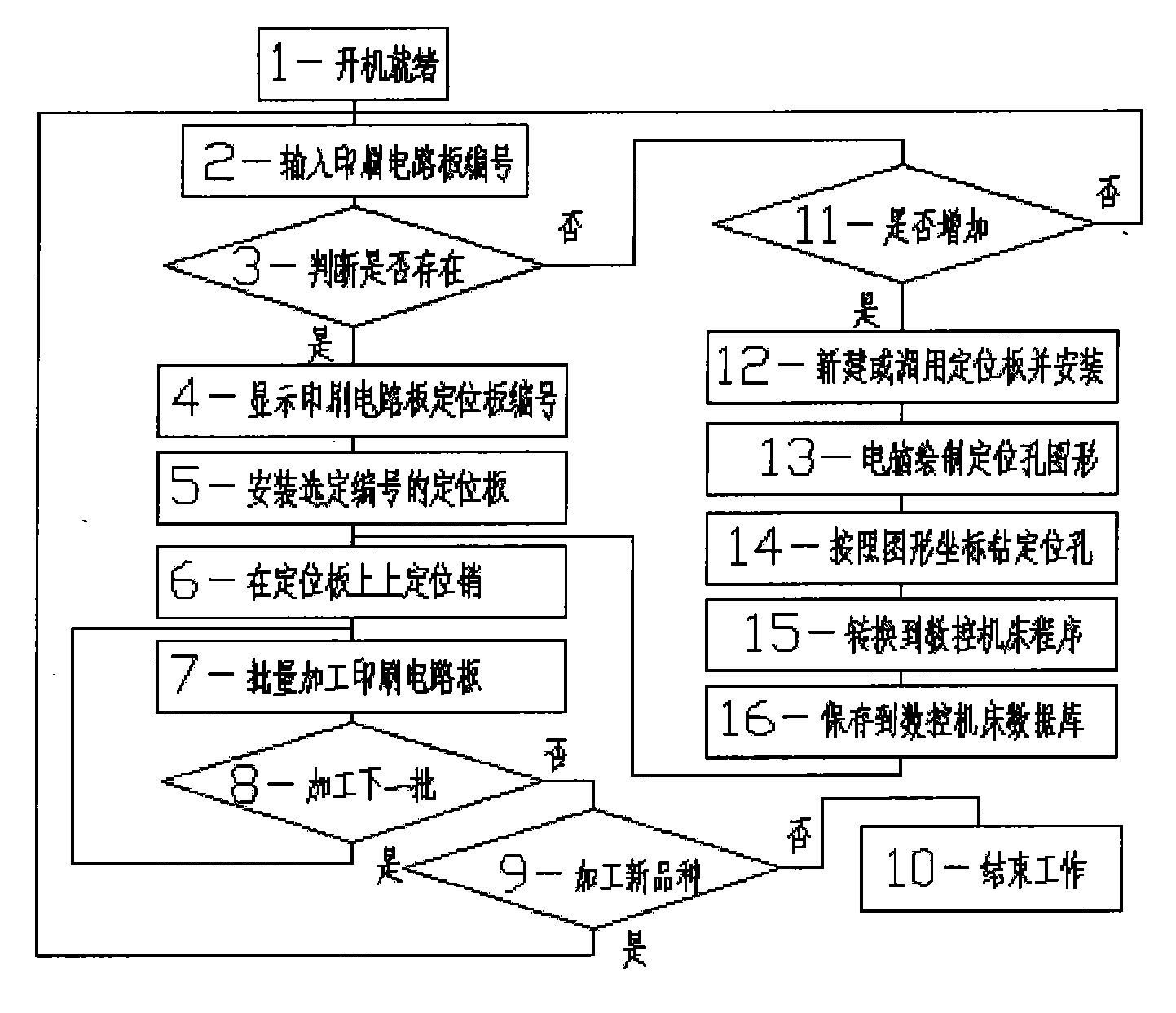

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0013] With reference to the accompanying drawings, the present invention includes booting ready 1 and finishing work 10, between the described booting ready 1 and finishing working 10 steps, at first is to manually input the printed circuit board number 2, and the computer of the CNC machine tool automatically searches the database to execute the step of judging whether it exists 3, and display "Yes" or "No" on the screen, the operator chooses to perform the following three steps according to the "Yes" or "No" displayed on the screen: processing the next batch 8, processing new varieties 9 And whether to increase 11, when selecting "no" of processing new variety 9, execute the step of finishing work 10 to close the machine tool.

[0014] Described step judges whether existence 3 is the step after being " yes " and is: display printed circuit board positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com