Method of manufacturing folding three face mask with in-depth fabric

A manufacturing method and fabric technology, applied in respiratory masks, filters for breathing, clothing, etc., can solve problems such as poor touch and hygienic effects, achieve good wearing feeling, good fine dust filtration performance, easy to carry and store. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

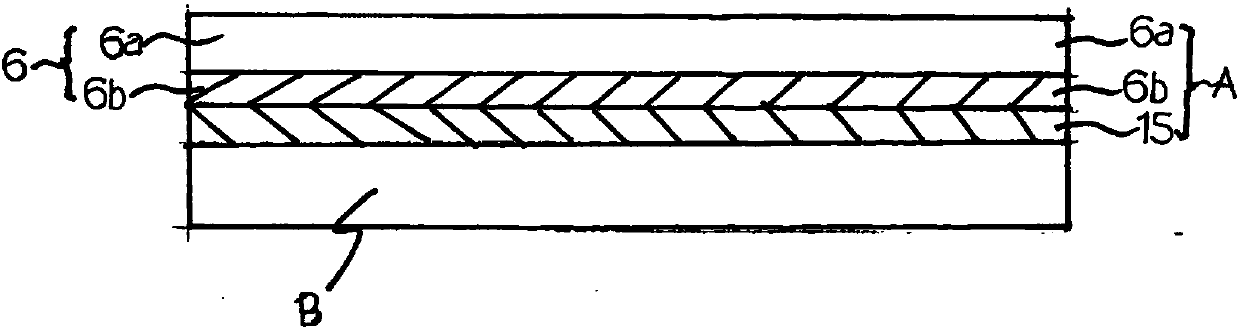

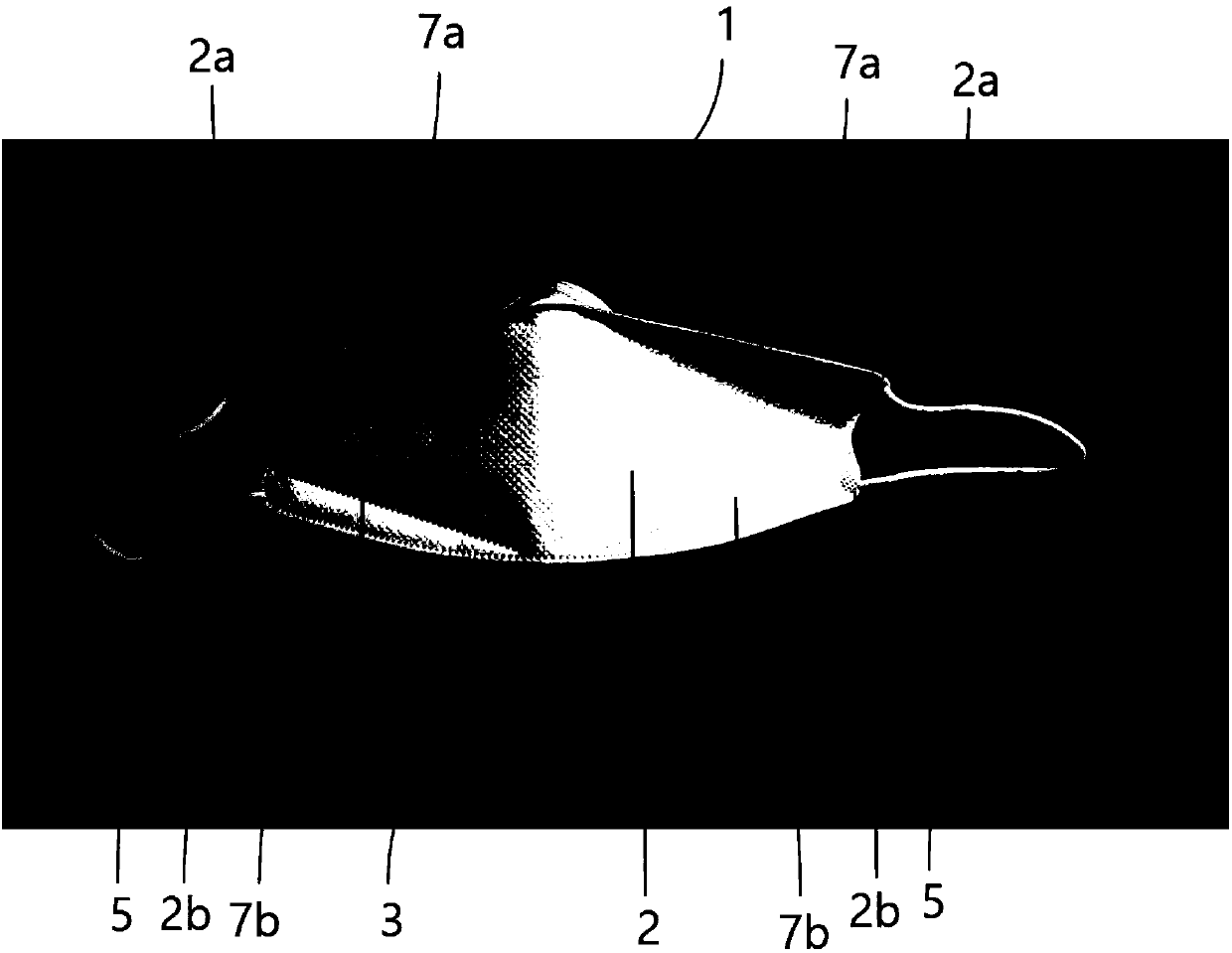

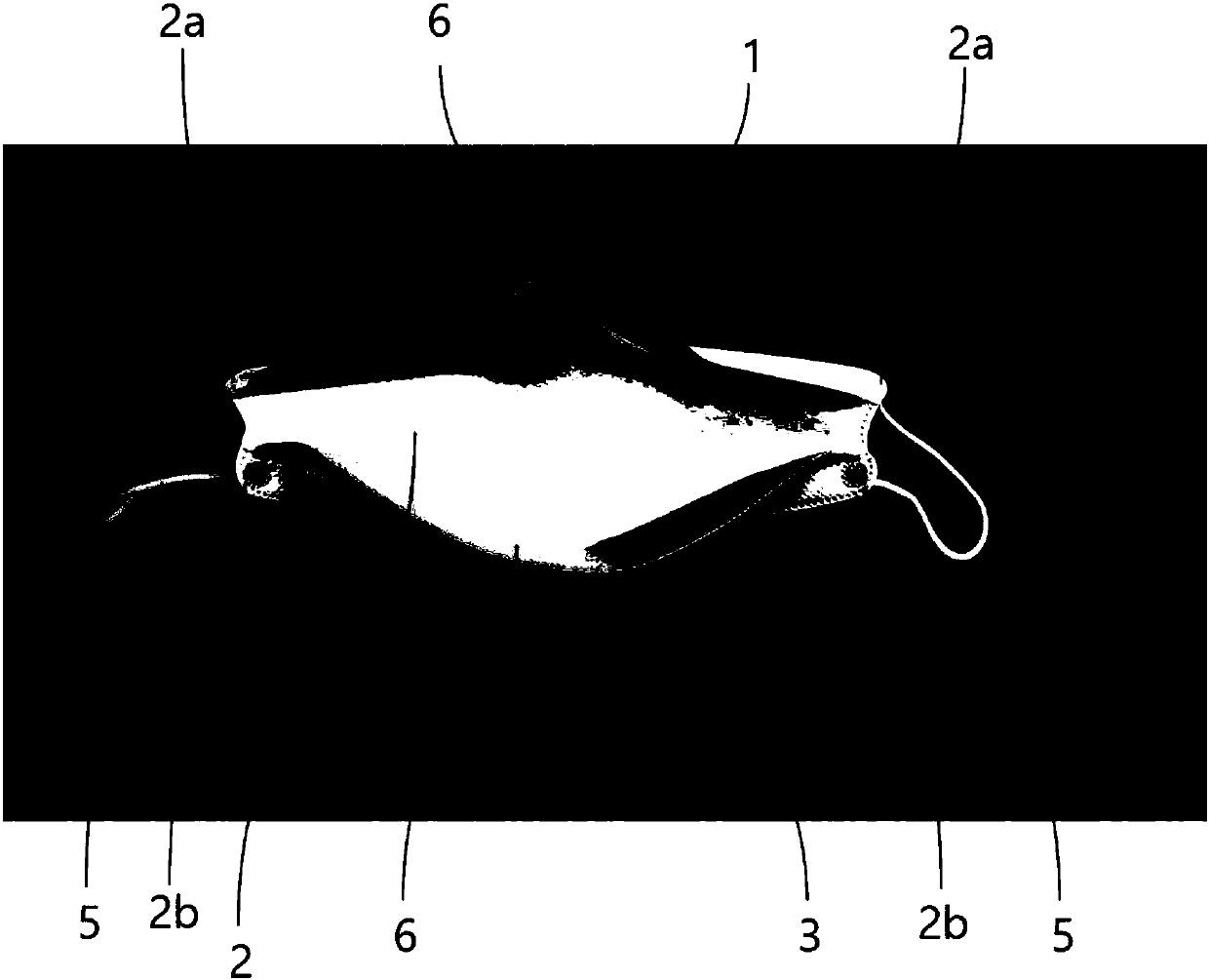

[0024] The present invention provides a method of manufacturing a three-sided foldable mask with deep fabric, which comprises: (i) a central filter 2 of synthetic fiber non-woven fabric located in the central part of the mask; (iii) by extending downward from the center filter 2 to form an upper filter 1 of a synthetic fiber nonwoven fabric folded along the fold line 7a in the longitudinal direction of the center filter 2; A lower filter 3 of synthetic fiber non-woven fabric folded along the folding line 7b in the longitudinal direction of 2; (iv) a nose pad 4 made of aluminum plate inserted into the central part of the upper filter 1; and (v) with Two ear loops 5 connected at each of both ends of the center filter 2; wherein a depth fabric 6 including a cotton fabric 6a and a resin layer 6b formed on the lower surface of the cotton fabric 6a is attached to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com