Pressing device

A pressing device and technology for stamping parts, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of workpiece scratching, workpiece damage, waste of working hours, etc., to save working hours, improve efficiency, and prevent easy damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

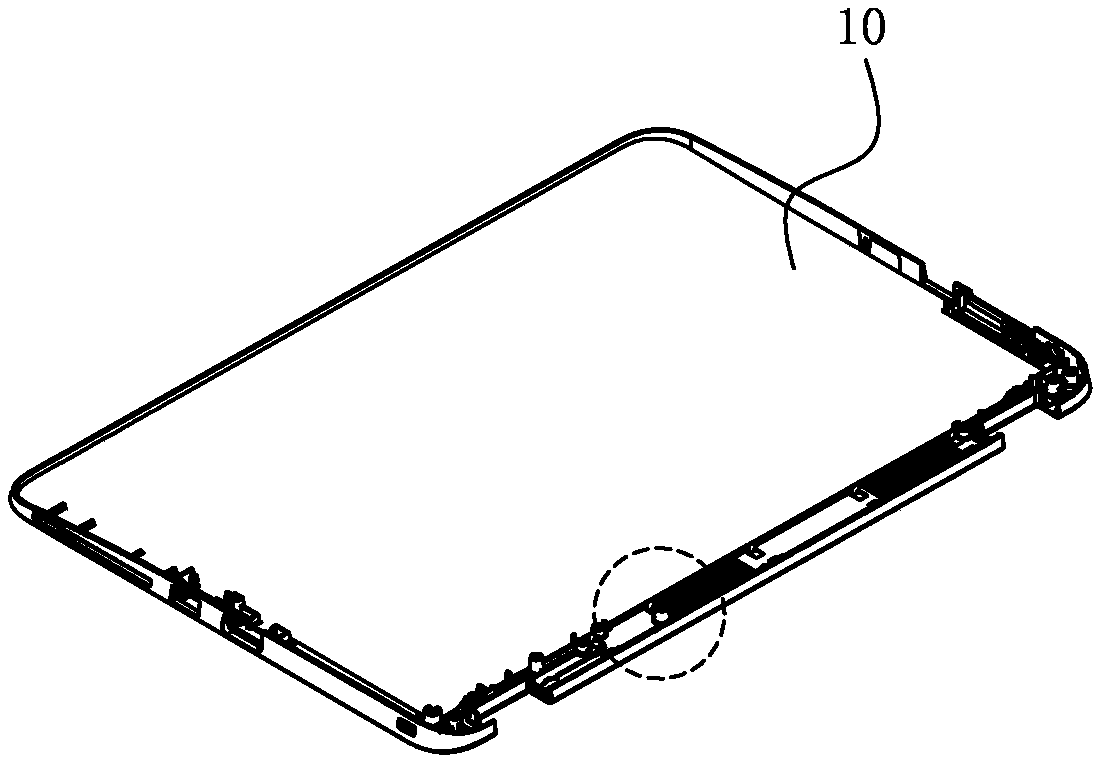

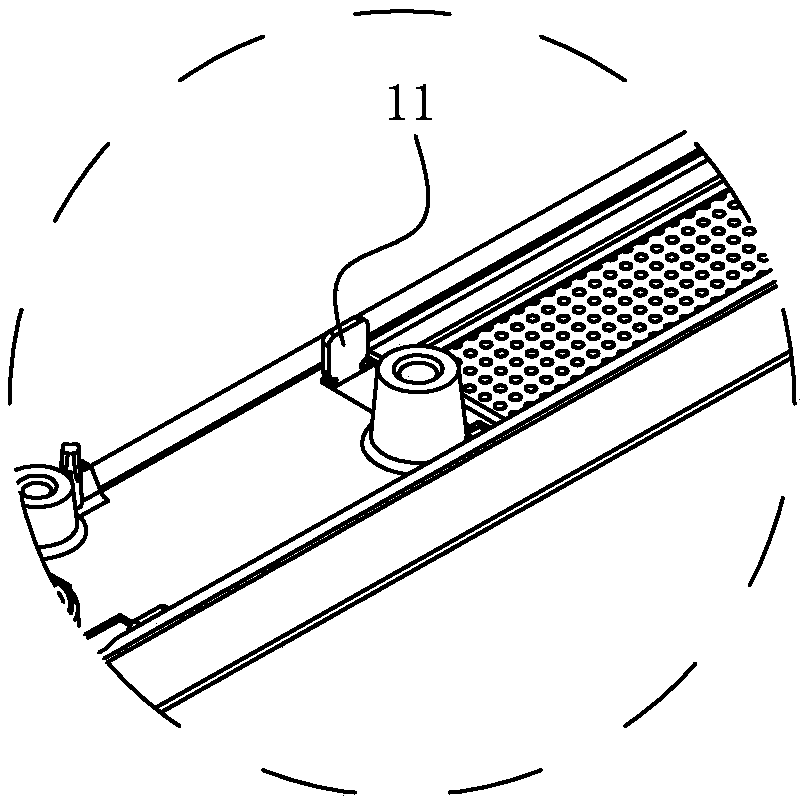

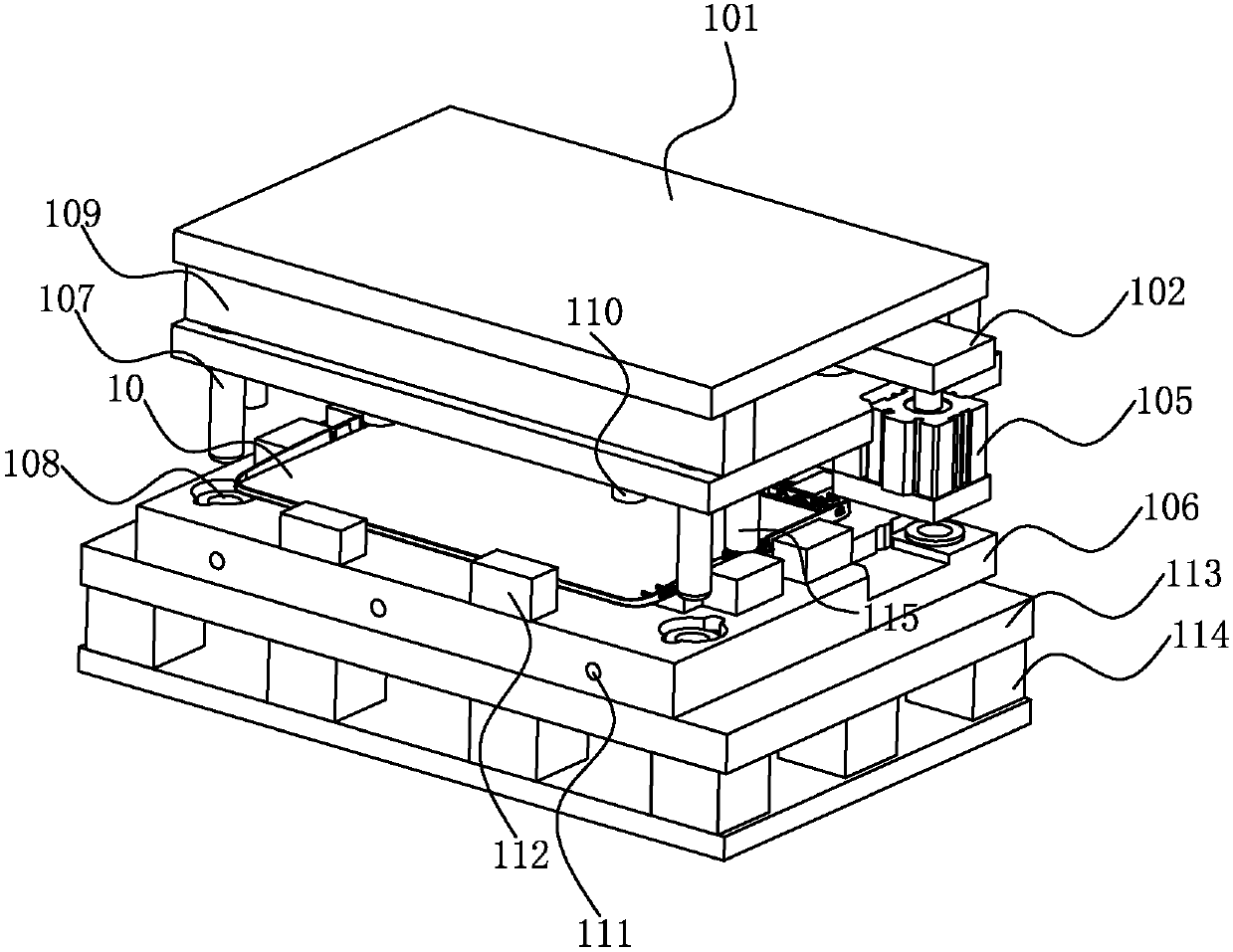

[0028] see image 3 , Figure 6 and Figure 7 as shown, image 3 It is a structural schematic diagram of the first working state of the pressing device of the present invention in a preferred embodiment; Figure 6 Illustrated as a partial structural diagram of the pressing device of the present invention; Figure 7 It is an exploded schematic diagram of a part of the structure of the pressing device of the present invention.

[0029] On the upper plate 101, a fixed block 102 is horizontally arranged in the middle thereof, and both ends of the fixed block 102 have extensions beyond the edge of the upper plate 101. The fixed block 102 is provided with several hollow grooves, each of which is connected to There is a punching part 103; a pressing block 104 is arranged under the fixing block 102, and a number of holes corresponding to the position of the hollow groove on the fixing block 102 and which can accommodate the punching part 103 passing through are provided on the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com