Injection mold fixture for plastic coating of internal spline guide rail of gear shaper

A technology of plastic coating and internal splines, which is applied in the direction of household components, household appliances, and other household appliances, etc., can solve problems such as the inability to meet the precision requirements of internal spline guide rails, and achieve improved wear resistance and shockproof effects, precision and efficiency Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these examples are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention All modifications of the valence form fall within the scope defined by the appended claims of the present application.

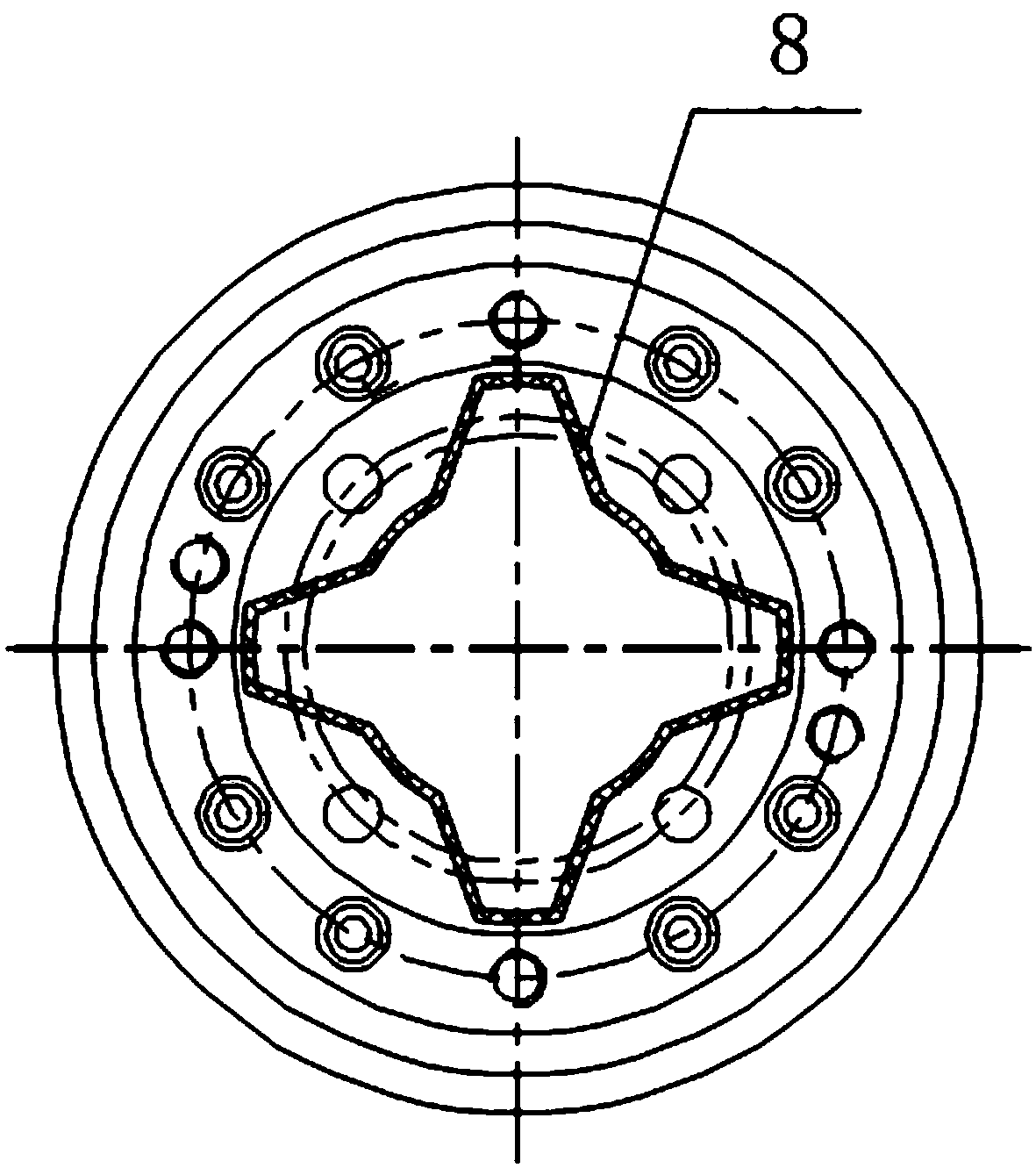

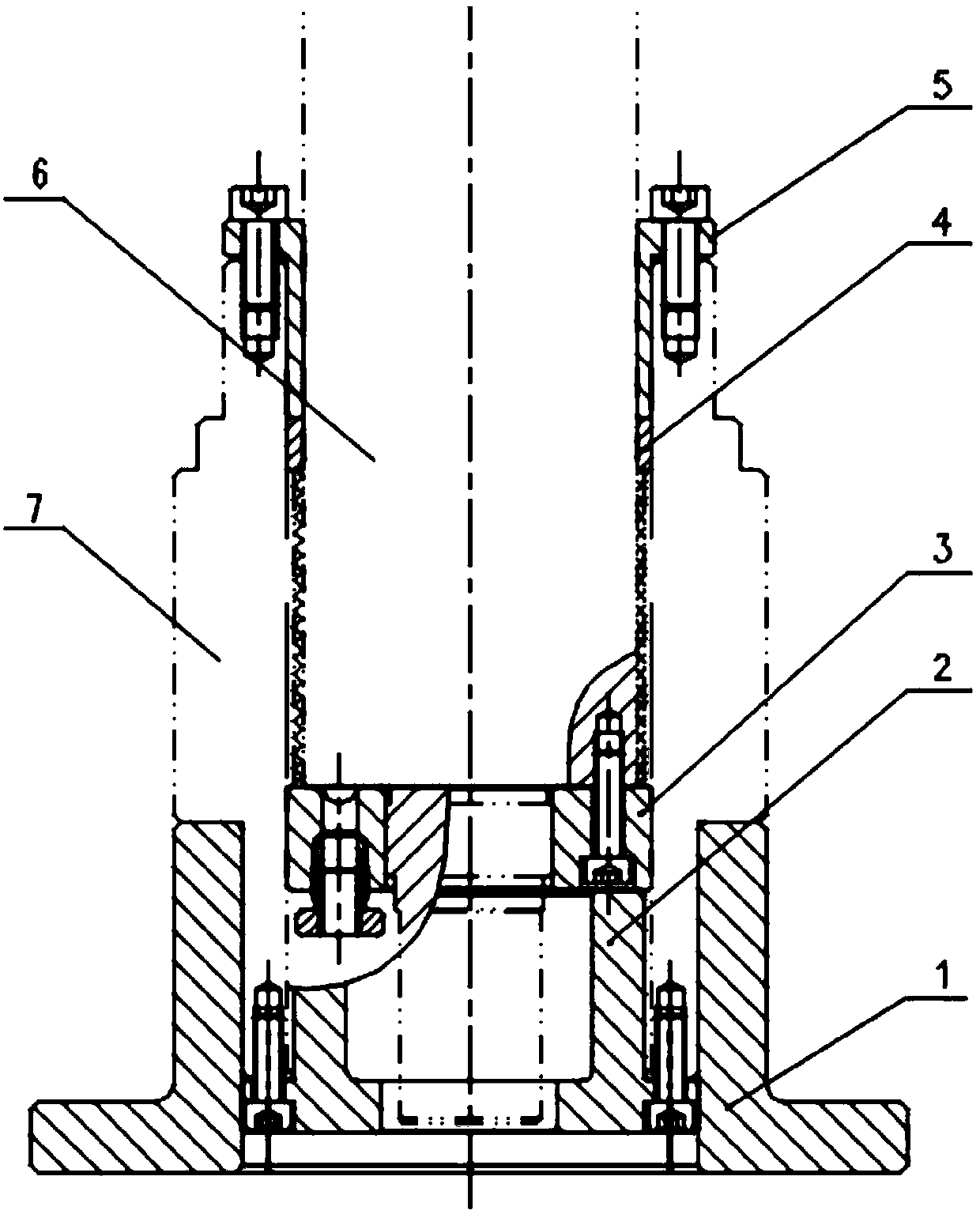

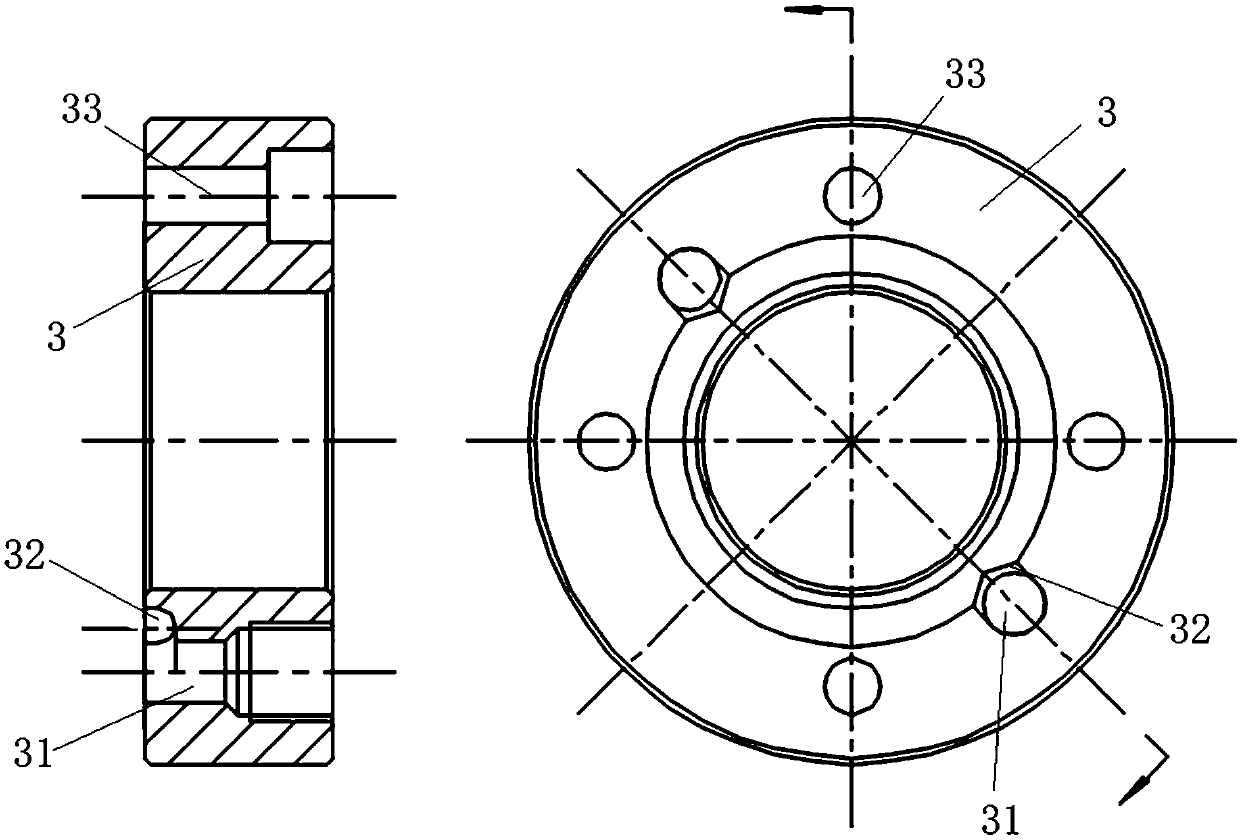

[0025] A plastic-coated injection molding tooling for spline guide rails in gear shaping machines, such as Figure 2-5 As shown, it includes a base 1, a lower gland 2, a positioning seat 3, an inner tooth mold cover 4, an upper gland 5, and a main shaft 6, wherein:

[0026] The base 1 is used for placing the inner spline guide rail 7 to be injected.

[0027] The lower gland 2 is fixed to the inner spline guide rail 7 to be injected. The lower gland 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com