Sweeper with rubber torsion spring alloy for conveyor belt

A conveyor belt and cleaner technology, applied in the direction of conveyor objects, cleaning devices, transportation and packaging, etc., can solve the problems of belt deviation and slippage, affecting the hardness of polyurethane elastomer, and the transport capacity cannot meet the design requirements, etc., to achieve excellent durability Grinding and scraping performance, excellent dynamic compensation performance, the effect of reducing the space required for installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

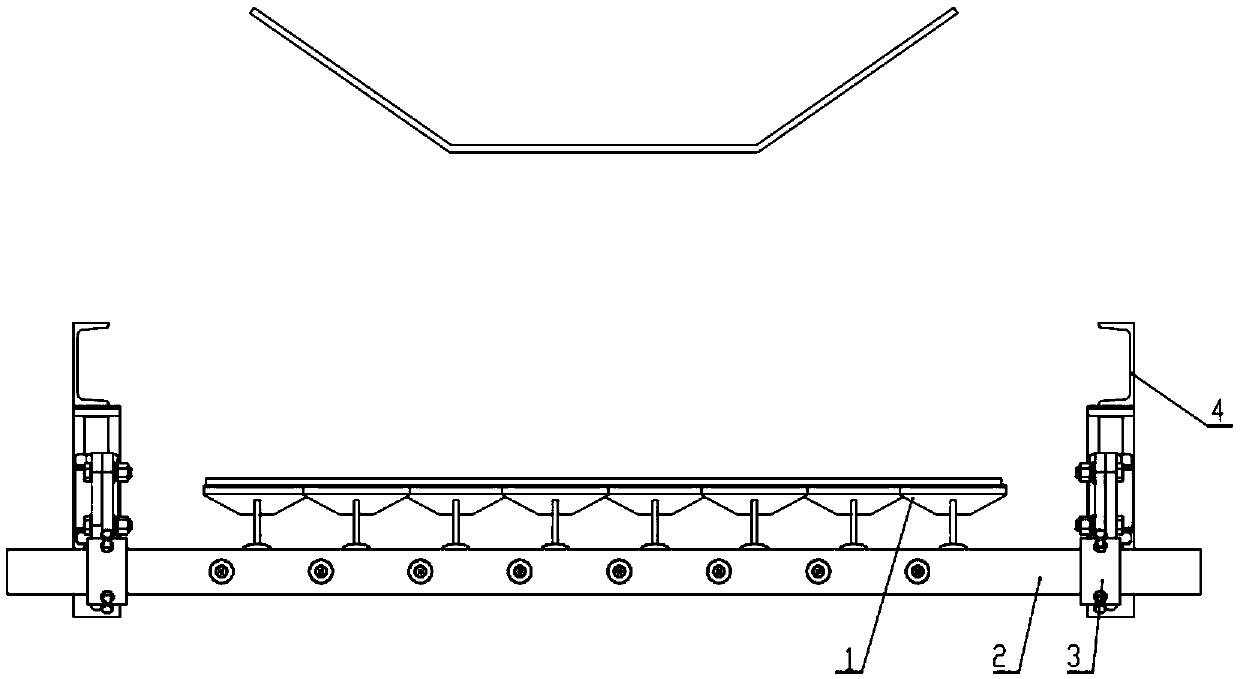

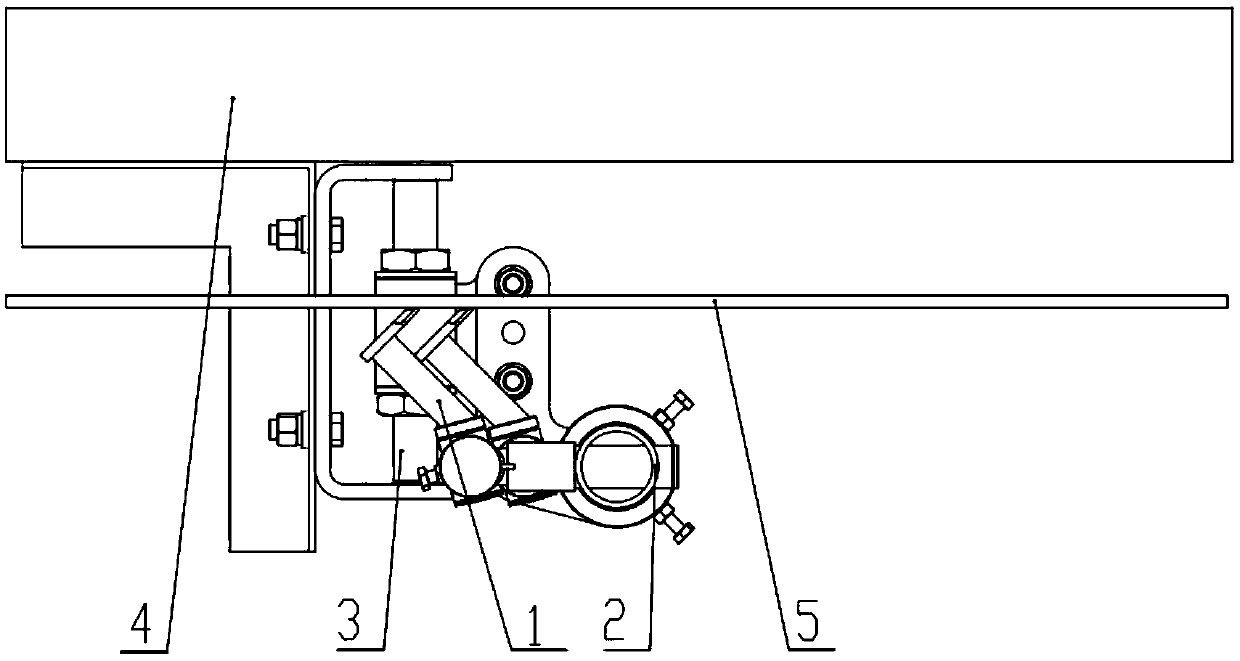

[0024] refer to figure 1 As shown, the conveyor belt rubber torsion spring alloy cleaner of the present invention includes a fixed adjustment assembly 3, a scraper frame 2, and a scraper unit 1. The fixed adjustment assembly 3 is installed on the channel steel 4 of the conveyor belt intermediate frame, and the scraper frame 2 Both ends are installed on the fixed adjustment assembly 3; the fixed adjustment assembly 3 is provided with a plurality of screws to cooperate with the channel steel 4 of the conveyor belt intermediate frame, and the adjustment of the height and angle of the scraper frame 2 is realized by adjusting the screws of the fixed adjustment assembly 3.

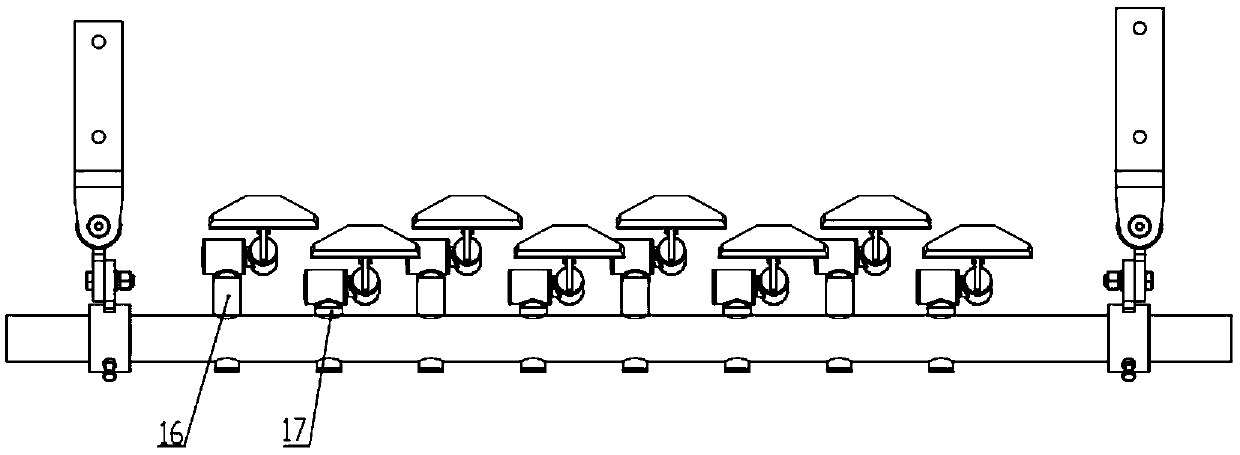

[0025] refer to figure 2 As shown, the scraper holder 2 includes a scraper bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com