Container truck anti-lifting device and container truck anti-lifting method based on machine vision

A technology of machine vision and truck collection, which is applied in the directions of safety devices, transportation and packaging, and load suspension components, etc. It can solve problems such as high cost, inability to deal with non-separation of unscanned surfaces, and increased work intensity and complexity of the driver himself. , to achieve the effect of dynamic monitoring and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

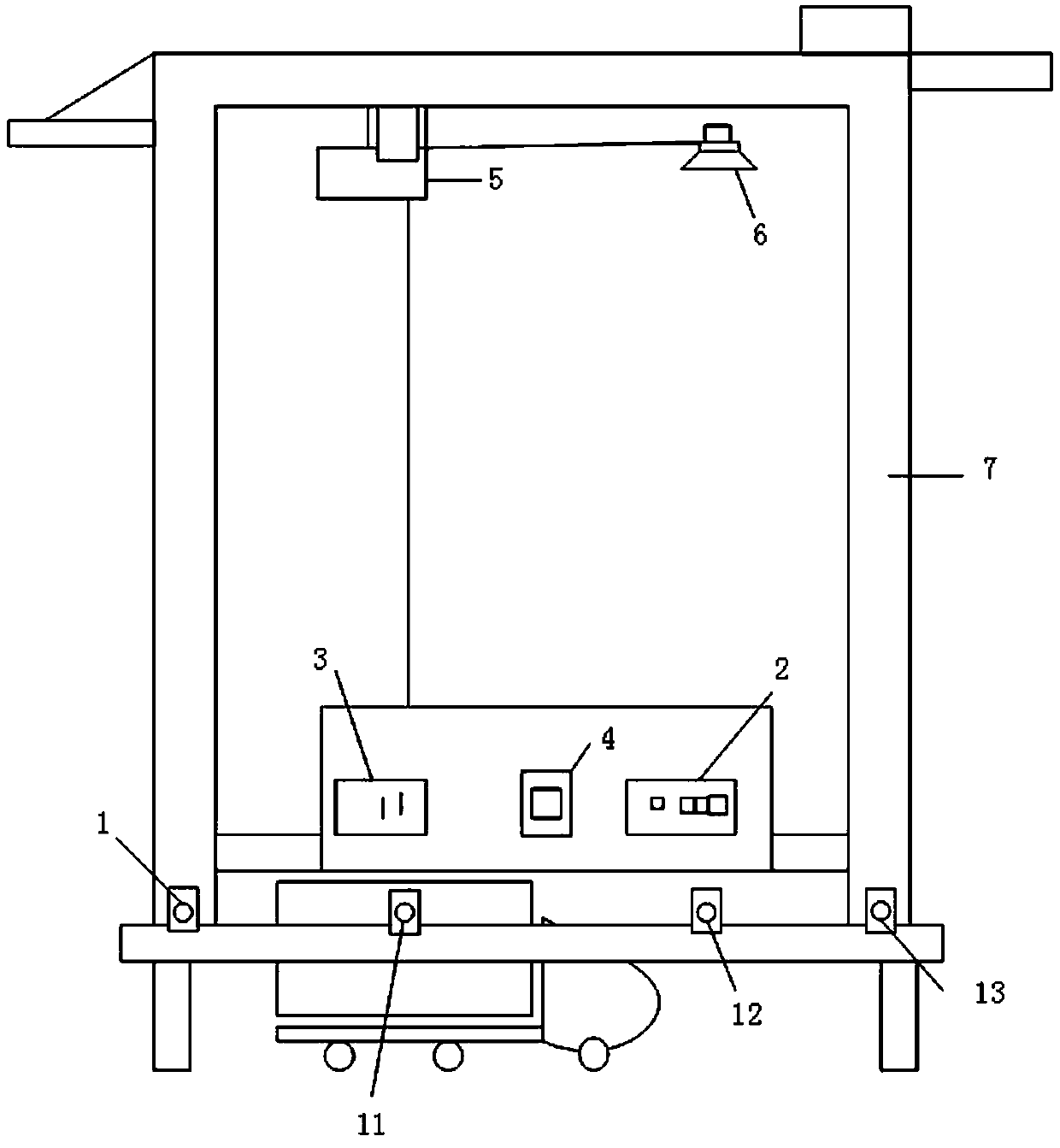

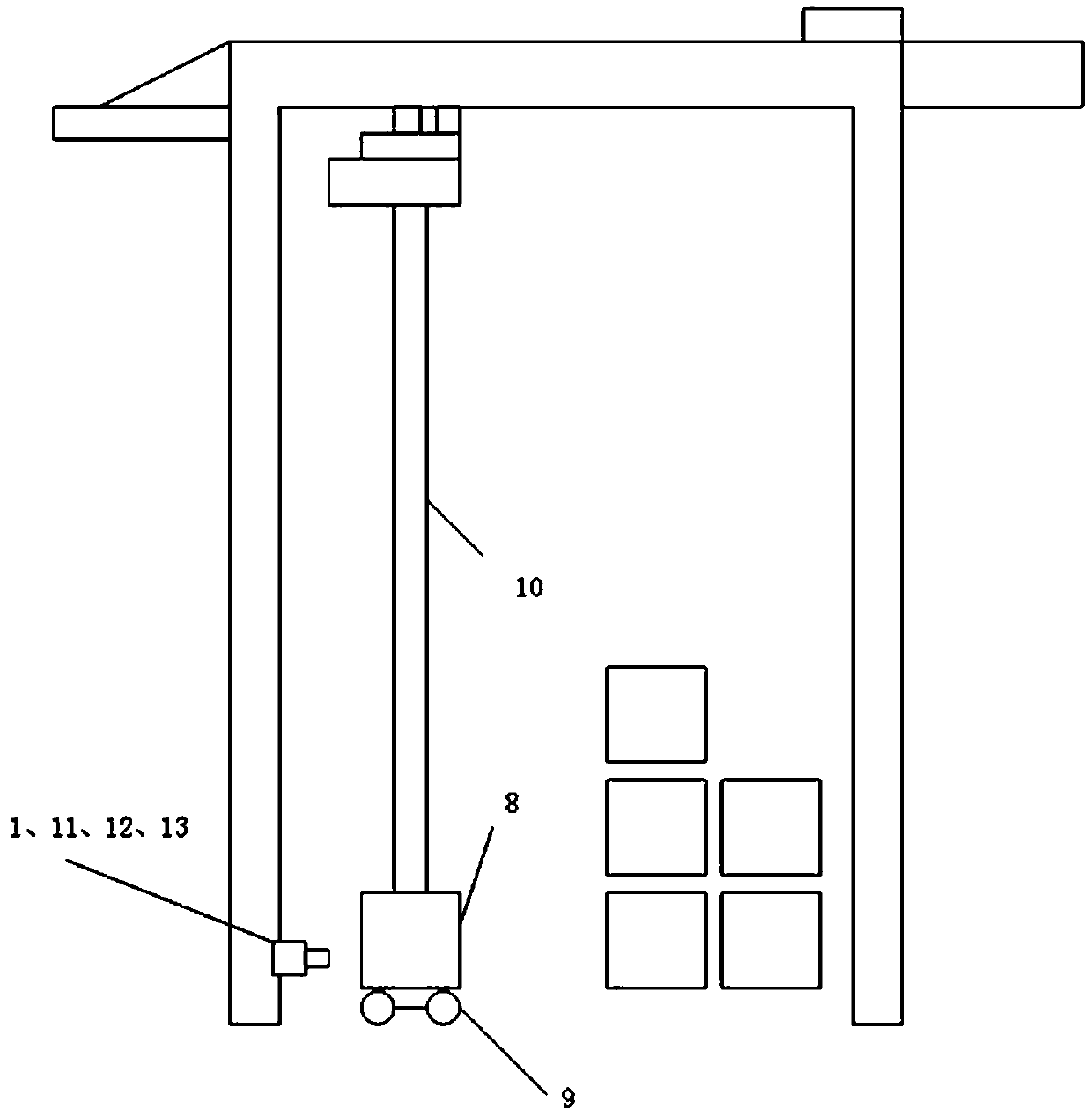

[0035] based on the following Figure 1 ~ Figure 2 , specifically describe the preferred embodiment of the present invention.

[0036] The present invention provides an anti-lifting device for collecting trucks based on machine vision, comprising:

[0037] At least four data acquisition modules are installed on the bottom bracket of the tire crane. The location of the data acquisition modules can ensure that all the outlines of the container and the collection truck are within the acquisition range of the data acquisition module. The data acquisition module is used to collect container and the image data of the set card;

[0038] The signal processing module is set in the electric room of the tire crane and connected to the data acquisition module, which is used to process the image data collected by the data acquisition module, and judge whether the collection truck is hoisted according to the position changes of the container and the collection truck;

[0039] The alarm mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com