Angular multi-stage cavitation generator

A generator and cavitation technology, applied in chemical instruments and methods, mechanical oscillation water/sewage treatment, water pollutants, etc., can solve problems such as incomplete cavitation reactions, and achieve effective degradation and high cavitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

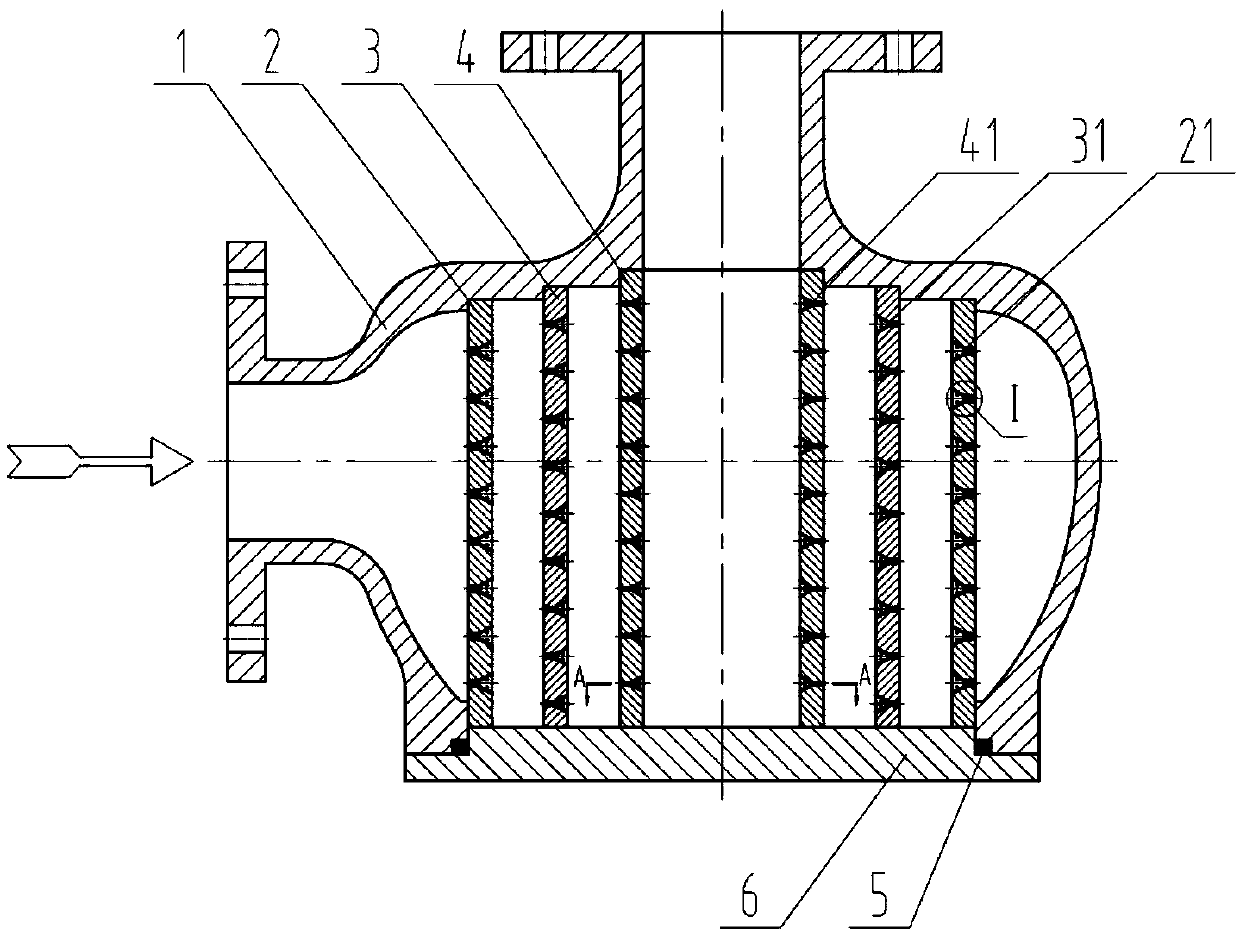

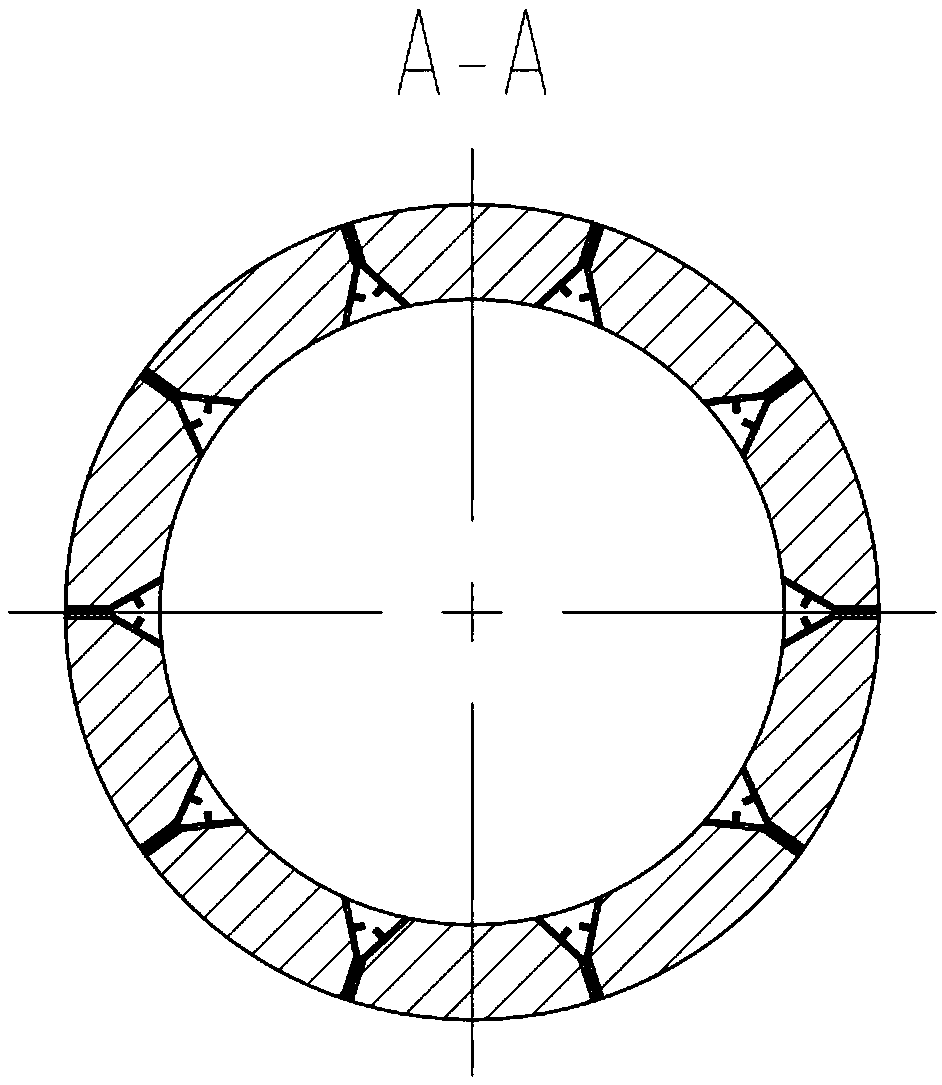

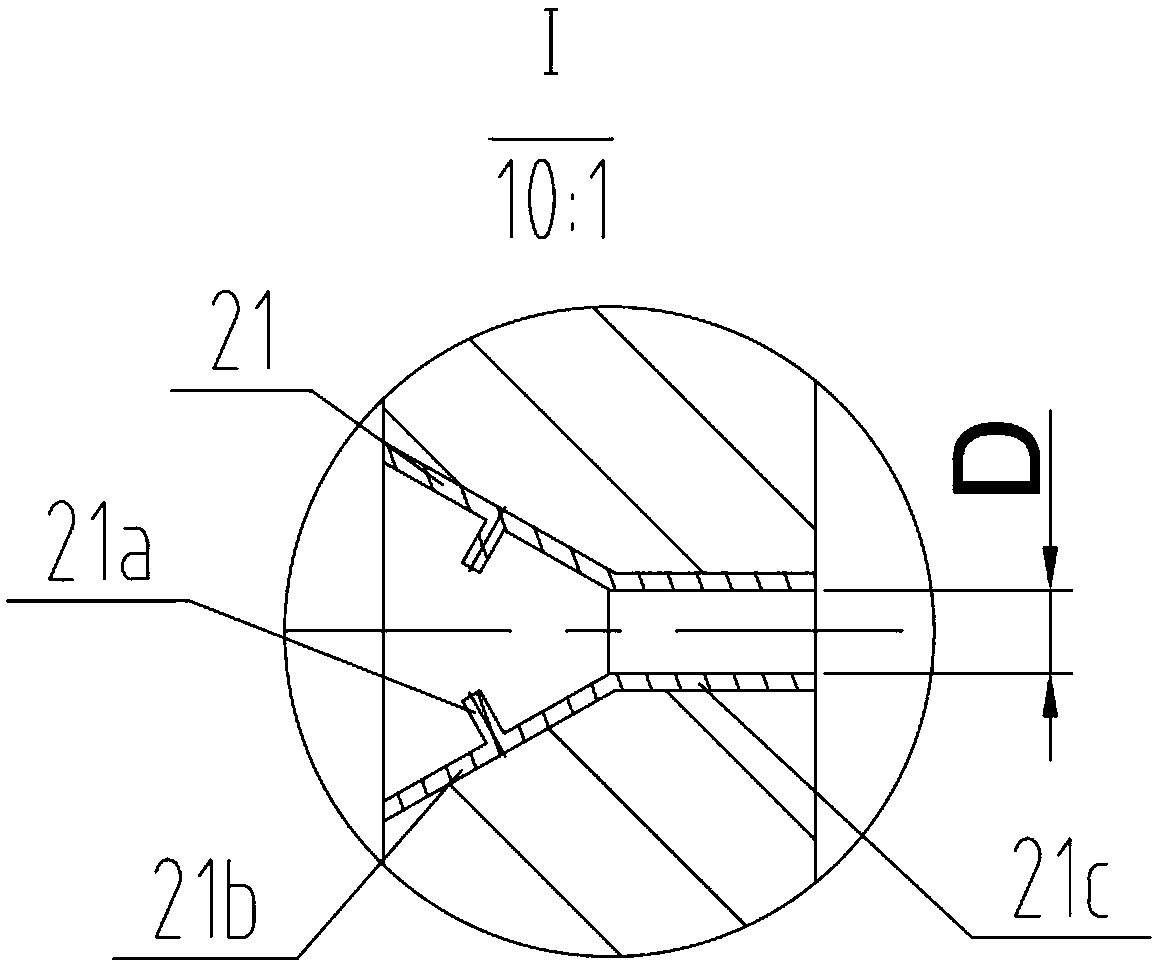

[0025] Such as figure 1 with figure 2 As shown, the angular multi-stage cavitation generator according to the present invention includes a casing 1, a primary cavitation sleeve 2, a secondary cavitation sleeve 3, a tertiary cavitation sleeve 4, a sealing ring 5 and a bottom Cover 6. The first-stage cavitation sleeve 2 , the second-stage cavitation sleeve 3 and the third-stage cavitation sleeve 4 are sequentially installed inside the housing 1 from outside to inside. The cavity of the housing is a drum structure, and the first-stage cavitation sleeve 2, the second-stage cavitation sleeve 3, and the third-stage cavitation sleeve 4 installed inside it are all cylindrical structures. A plurality of primary cavitation occurrence holes 21 are uniformly distributed on the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com