Fe-N compound doped carrier catalyst, preparation method and application

A compound and catalyst technology, applied in chemical instruments and methods, water pollutants, oxidized water/sewage treatment, etc., can solve the problems of low utilization rate of hydrogen peroxide, low catalytic activity, large sludge production, etc., and achieve rapid The effect of effective degradation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment, the present invention will be further described:

[0031] Sources of materials and reagents:

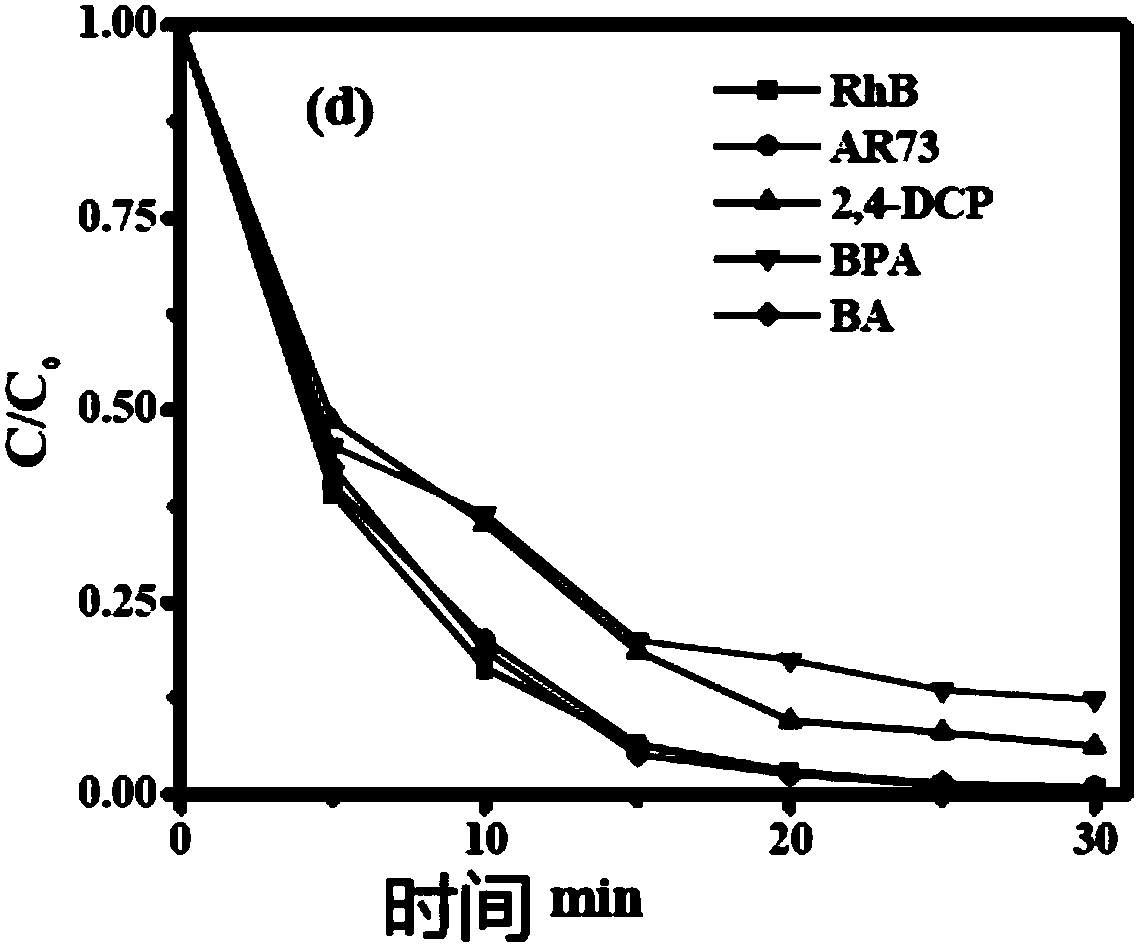

[0032] Carbon black (acetylene carbon black, 100% compressed) was purchased from STREM CHEMICALS Co., Ltd., anhydrous ferric chloride (FeCl 3 ), imidazole (Im), methanol, 2,4-dichlorophenol (2,4-DCP), bisphenol A (BPA) and benzoic acid (BA) were purchased from Shanghai Sinopharm Chemical Reagent Co., Ltd. Acid red 73 (AR73) and rhodamine B (Rh B) were purchased from Chengdu West Asia Chemical Reagent Co., Ltd. 5,5-Dimethyl-1-pyrroline-N-oxide (DMPO) was purchased from Sigma-Aldrich Company.

[0033] Catalyst preparation

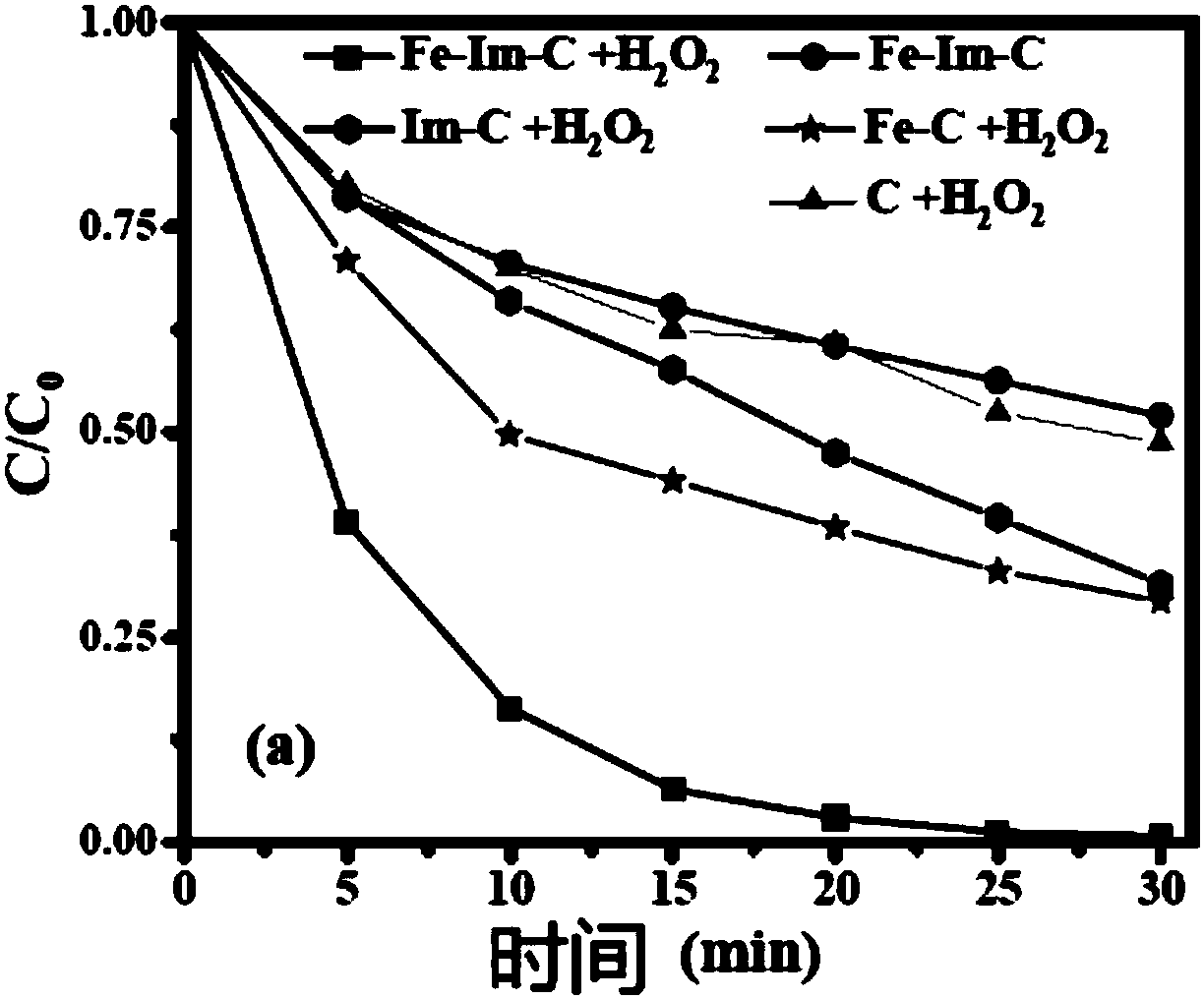

[0034] 4.25g carbon black, 2.433g FeCl 3 (0.015mol) and 3.40g imidazole (0.05mol) were added to 150mL ethanol and mixed thoroughly, and kept stirring at room temperature for more than 6h, then dried the ethanol by a rotary evaporator, dried in an oven at 80°C to remove residual ethanol, and then dried The final sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Most probable aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com