Preparation method and application of self-supporting block photocatalyst

A photocatalyst and self-supporting technology, which is applied in the field of photocatalytic materials, can solve the problems that cannot be recycled, red phosphorus is difficult to recycle, etc., and achieve the effect of easy recycling and effective degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

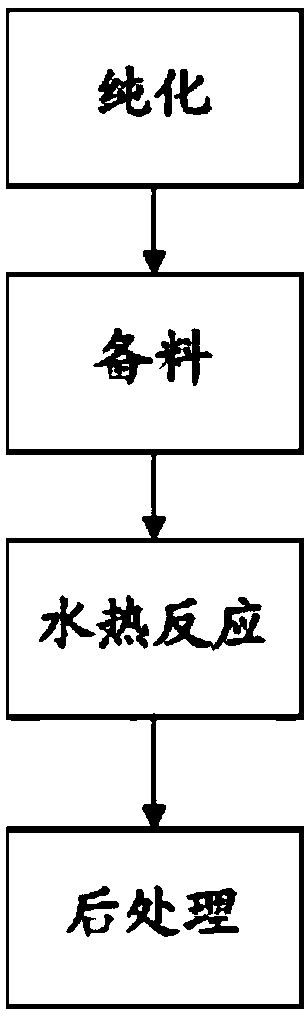

Method used

Image

Examples

Embodiment 1

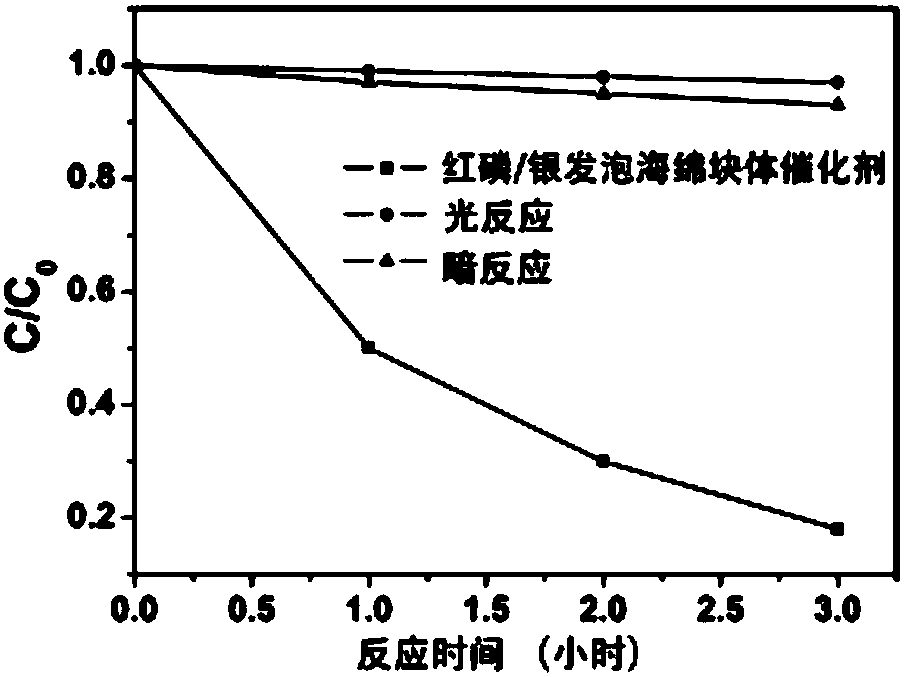

[0034] This example is a specific example of preparing the self-supporting bulk photocatalyst product 1 .

[0035] Add 2g of ordinary red phosphorus into a 20ml polytetrafluoroethylene-lined reaction kettle, add 15ml of water, place in an oven, and heat at a constant temperature of 100°C for 24h. The obtained solid product was centrifuged, washed, and dried in sequence to obtain the powdered purified product 1, which was placed in a desiccator for later use. Among them, the purity of the purified product 1 is greater than 99%.

[0036] After dissolving 0.05g of silver salt in 5ml of water, mix with 0.1g of purified product 1 to obtain suspension 1; wherein, the mixing method is: ultrasonic oscillation; the temperature of ultrasonic oscillation is 20°C, and the time of ultrasonic oscillation is 15min.

[0037] The suspension 1 was transferred to a 20ml polytetrafluoroethylene-lined high-pressure reactor, and the reactor was placed in an oven for hydrothermal reaction, and heat...

Embodiment 2

[0041] This example is a specific example of preparing the self-supporting block photocatalyst product 2.

[0042] Add 2g of ordinary red phosphorus into a 20ml polytetrafluoroethylene-lined reaction kettle, add 15ml of water, place in an oven, and heat at a constant temperature of 200°C for 15h. The obtained solid product was successively centrifuged, washed, and dried to obtain the powdered purified product 2, which was placed in a desiccator for later use. Wherein, the purity of the purified product 2 is greater than 99%.

[0043] After dissolving 0.3g of silver nitrate in 10ml of water, mix it with 0.1g of purified product 2 to obtain suspension 2; wherein, the mixing method is: ultrasonic oscillation; the temperature of ultrasonic oscillation is 30°C, and the time of ultrasonic oscillation is 40min.

[0044] The suspension 2 was transferred to a 20ml polytetrafluoroethylene-lined high-pressure reactor, and the reactor was placed in an oven for hydrothermal reaction, and ...

Embodiment 3

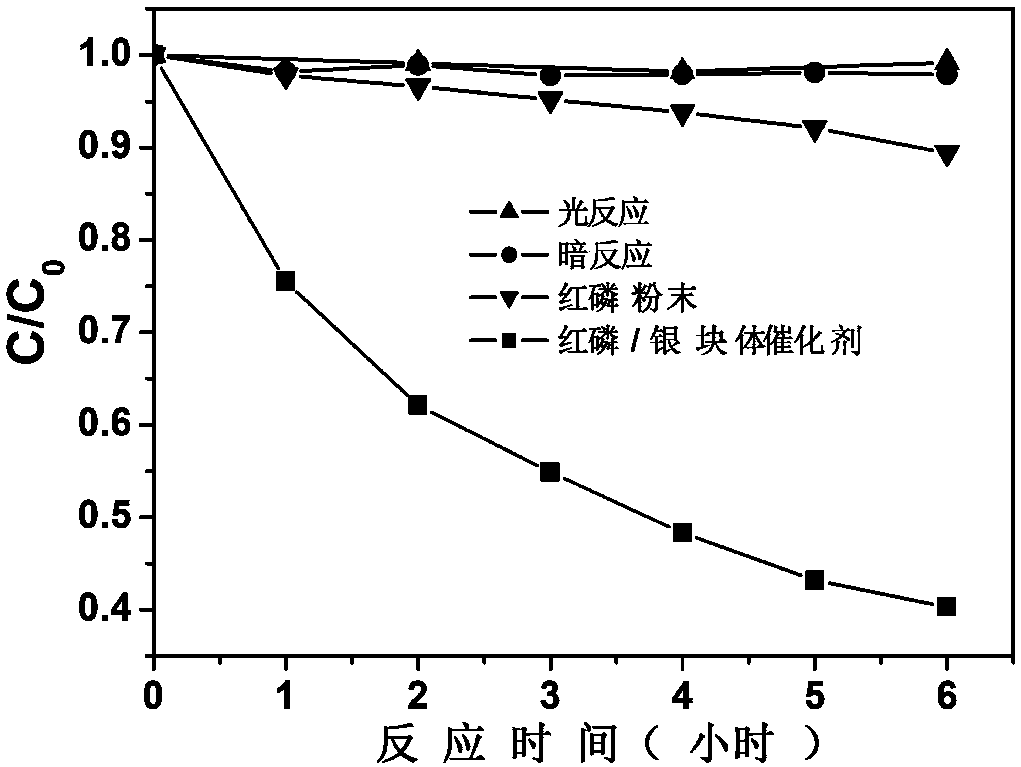

[0048] This example is a specific example of preparing the self-supporting bulk photocatalyst product 3 .

[0049] Add 2g of ordinary red phosphorus into a 20ml polytetrafluoroethylene-lined reaction kettle, add 15ml of water, place in an oven, and heat at a constant temperature of 150°C for 2h. The resulting solid product was centrifuged, washed, and dried in sequence to obtain the powdered purified product 3, which was placed in a desiccator for later use. Among them, the purity of the purified product 3 is greater than 99%.

[0050] Dissolve 0.88g of silver salt in 16ml of water, and mix with 1g of purified product 3 to obtain suspension 3; the mixing method is: ultrasonic vibration; the temperature of ultrasonic vibration is 40°C, and the time of ultrasonic vibration is 10 minutes.

[0051] The suspension 3 was transferred to a 20ml polytetrafluoroethylene-lined high-pressure reactor, and the reactor was placed in an oven for hydrothermal reaction, and heated at a constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com