Underground garage roof deformation joint waterproof joint and building method

An underground garage and construction method technology, applied in construction, water conservancy projects, underwater structures, etc., can solve problems such as excessive shear or axial deformation of rubber waterstops, lack of repair means, loss of waterproof function, etc. The effect of reducing the risk of water leakage, improving construction efficiency and enhancing waterproof safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

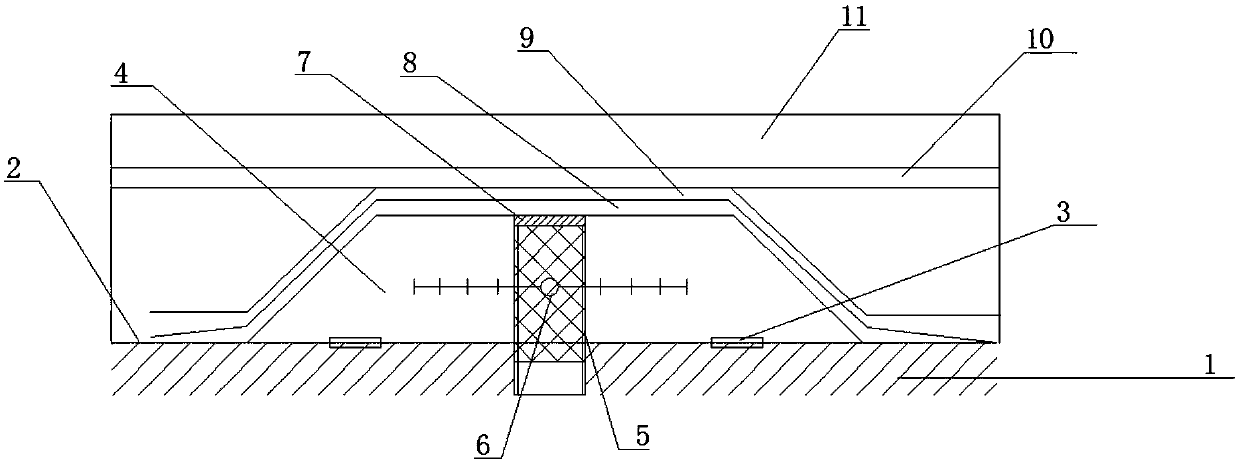

[0030] The present invention will be described further in conjunction with accompanying drawing now.

[0031] A method for constructing waterproof joints of underground garage roof deformation joints according to the present invention mainly includes the following process steps:

[0032] 1. Cast-in-place bottom structure base 1;

[0033] 2. Lay a 100mm thick emulsified asphalt wood wool board 2 on the structural base;

[0034] 3. After the rough surface is chiseled on the upper end of the emulsified asphalt wood wool board 2, a waterproof blocking strip 3 is poured;

[0035] 4. Pour a trapezoidal waterproof protruding base surface 4 on the emulsified asphalt wood wool board 2 or pour the rough surface, and reserve a layer of cracks in the middle when pouring the waterproof protruding base surface 4;

[0036] 5. Lay a layer of waterstop waterproof layer 5 fully covered with SBS waterproof membrane or self-adhesive waterproof membrane on the inner wall of the gap, and then ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com