Wear checking device for brake pad of oil-cooling multi-piece brake

A wear inspection, cold multi-piece technology, applied in the direction of brake type, mechanical equipment, etc., can solve the problems of small available space for operators, difficult measurement, long time consumption, etc., to reduce non-fault downtime, and the inspection process is simple and intuitive. The effect of reducing the workload of inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following description illustrates specific embodiments of the invention sufficiently to enable those skilled in the art to practice and reproduce it.

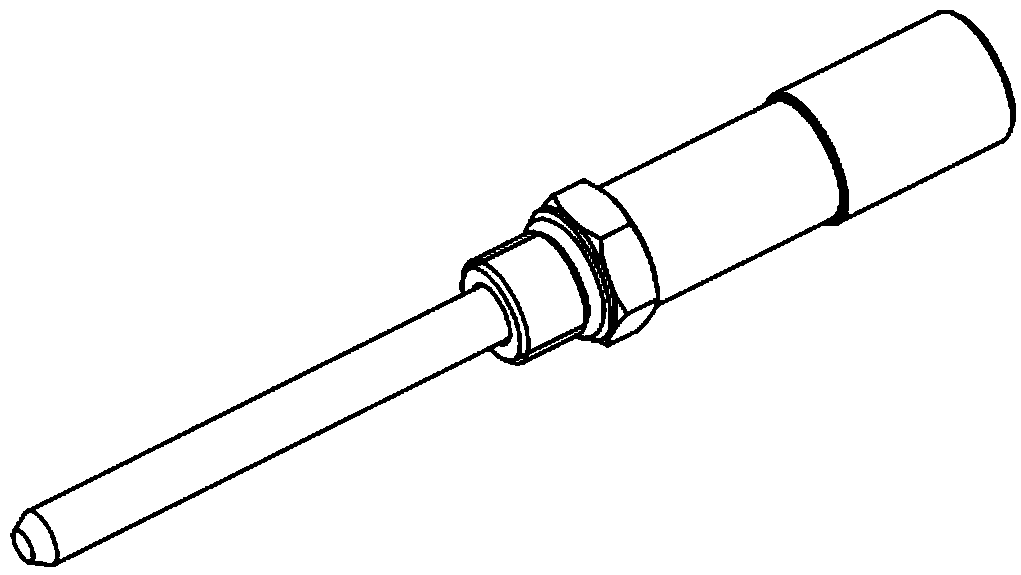

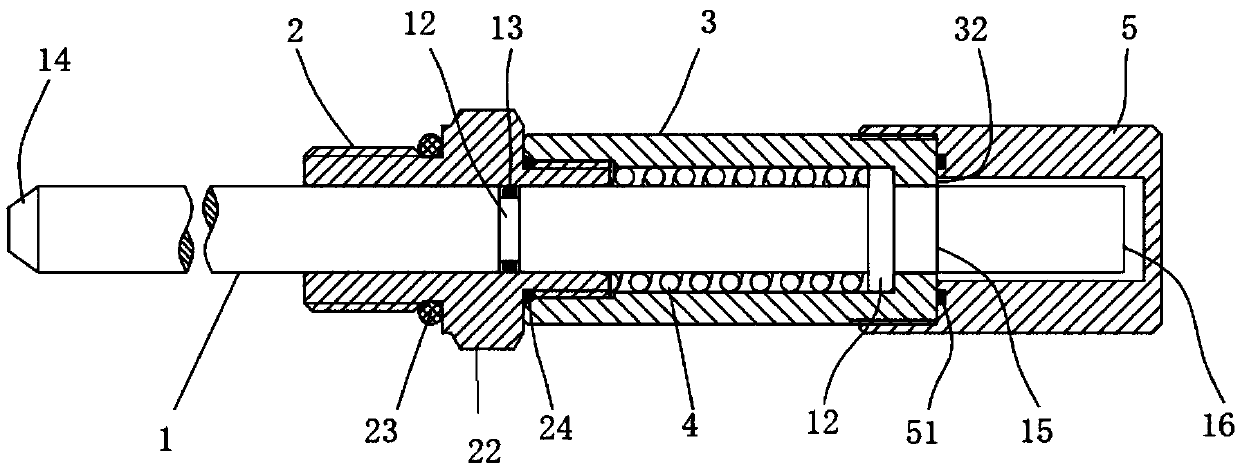

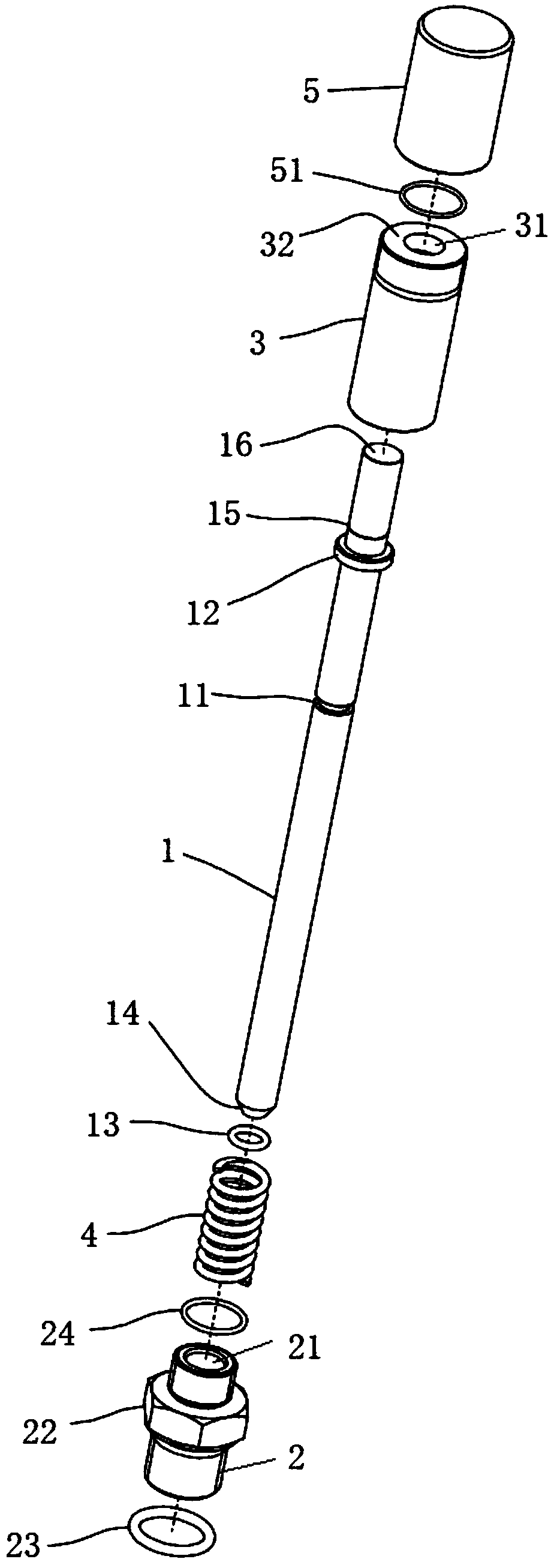

[0019] Such as figure 1 Shown is the structural diagram of the oil-cooled multi-plate brake brake pad wear inspection device in the present invention; as figure 2 As shown, it is a sectional view of the oil-cooled multi-plate brake brake pad wear inspection device in the present invention; as image 3 Shown is an exploded view of the brake pad wear inspection device for oil-cooled multi-plate brakes in the present invention.

[0020] The oil-cooled multi-disc brake brake pad wear inspection device has a structure including: an inspection rod 1, a fixed seat 2, a sleeve 3, a spring 4, and a protective cap 5.

[0021] The inspection rod 1 is provided with an inspection rod groove 11 and a flange 12 on the side wall, and a first sealing ring 13 is installed in the inspection rod groove 11 . The inspection rod 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com