An easy to install recessed ceiling led downlight

A technology of LED downlights and ceilings, which is applied to the parts of lighting devices, lighting devices, lighting auxiliary devices, etc., can solve the problems of easy to be caught by spring clips, high risk, inconvenience, etc., and achieve simple and fast installation and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

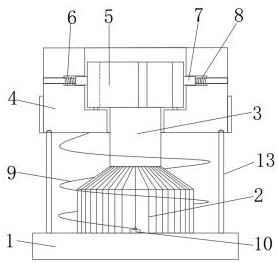

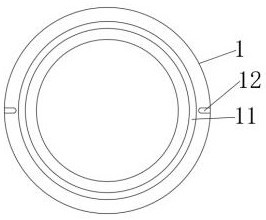

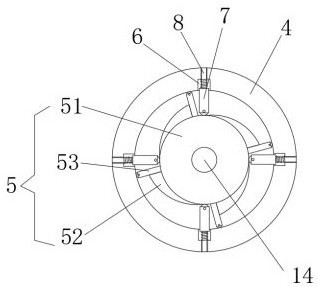

[0029] Embodiment: When installing, insert the fixing sleeve 4 into the installation hole of the downlight on the ceiling or the ceiling, turn the panel 1, and the panel 1 drives the rotating column 51 to rotate through the heat dissipation cover 2 and the connecting pipe 3, and the rotating column 51 passes through the involute protrusion 52. Push the ladder bar 7 out of the fixing sleeve 4. After the baffle plate 53 blocks the ladder bar 7 and continues to rotate, pull the support bar 13 out from the limit groove 12, and then pull it out from the hole of the downlight, and slowly release the panel 1. Under the tension of the compression spring 9, the top of the panel 1 fits with the ceiling or the bottom of the suspended ceiling. When dismounting, the panel 1 is directly pulled to rotate in the opposite direction, the rotating column 51 is reversed, and the ladder rod 7 is retracted under the action of the return spring 8 In the stepped extrusion hole 6, the fixing sleeve 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com