System and method for online evaluation of high-temperature pressure-bearing component defect of steam turbine

A pressure-bearing component and defect assessment technology, applied in the field of steam turbines, can solve problems such as failure to meet pressure-bearing component defects, poor calculation accuracy of crack growth life, and inability to guide maintenance personnel to deal with defects, so as to eliminate potential safety hazards, prevent non-stop, The effect of ensuring operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

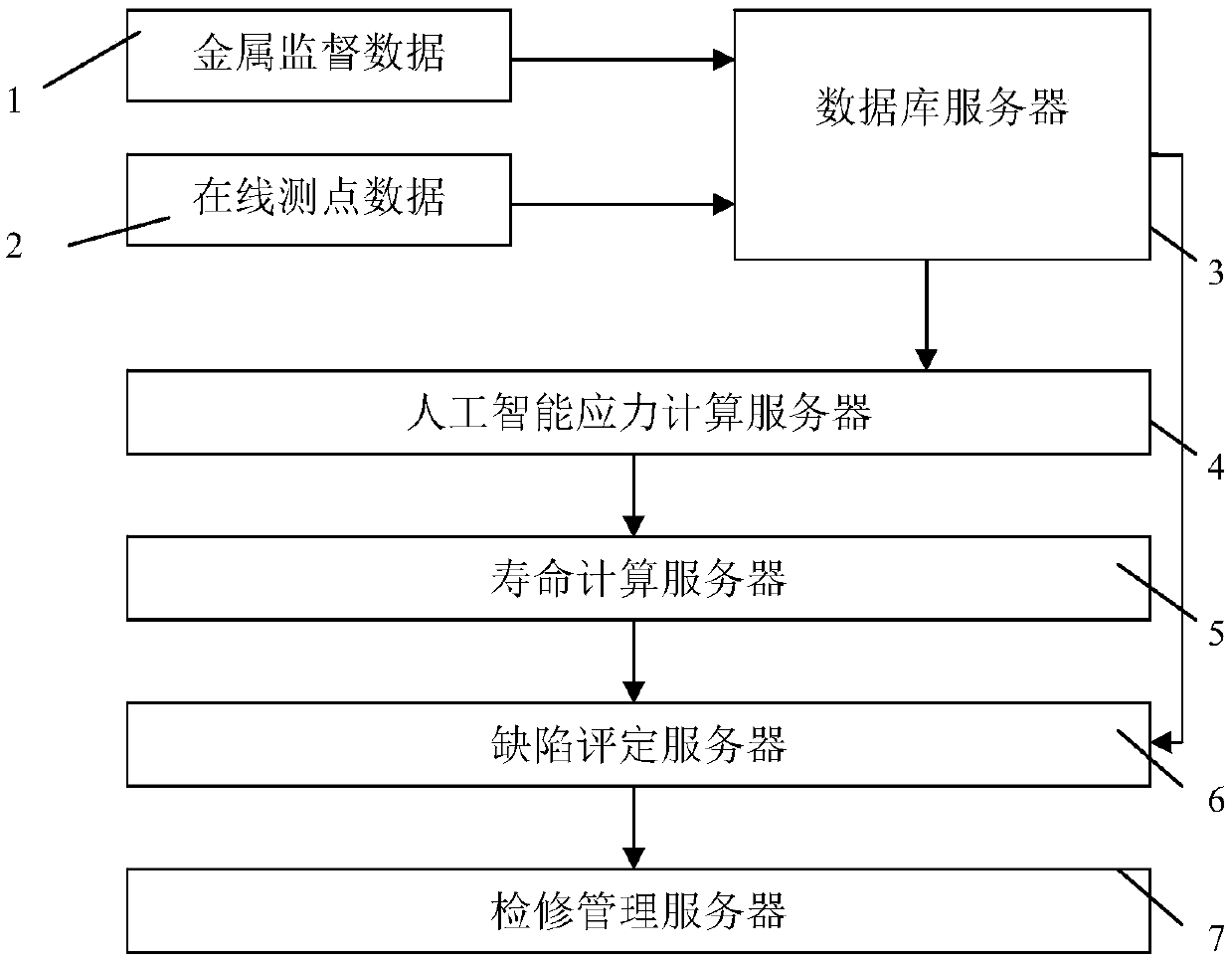

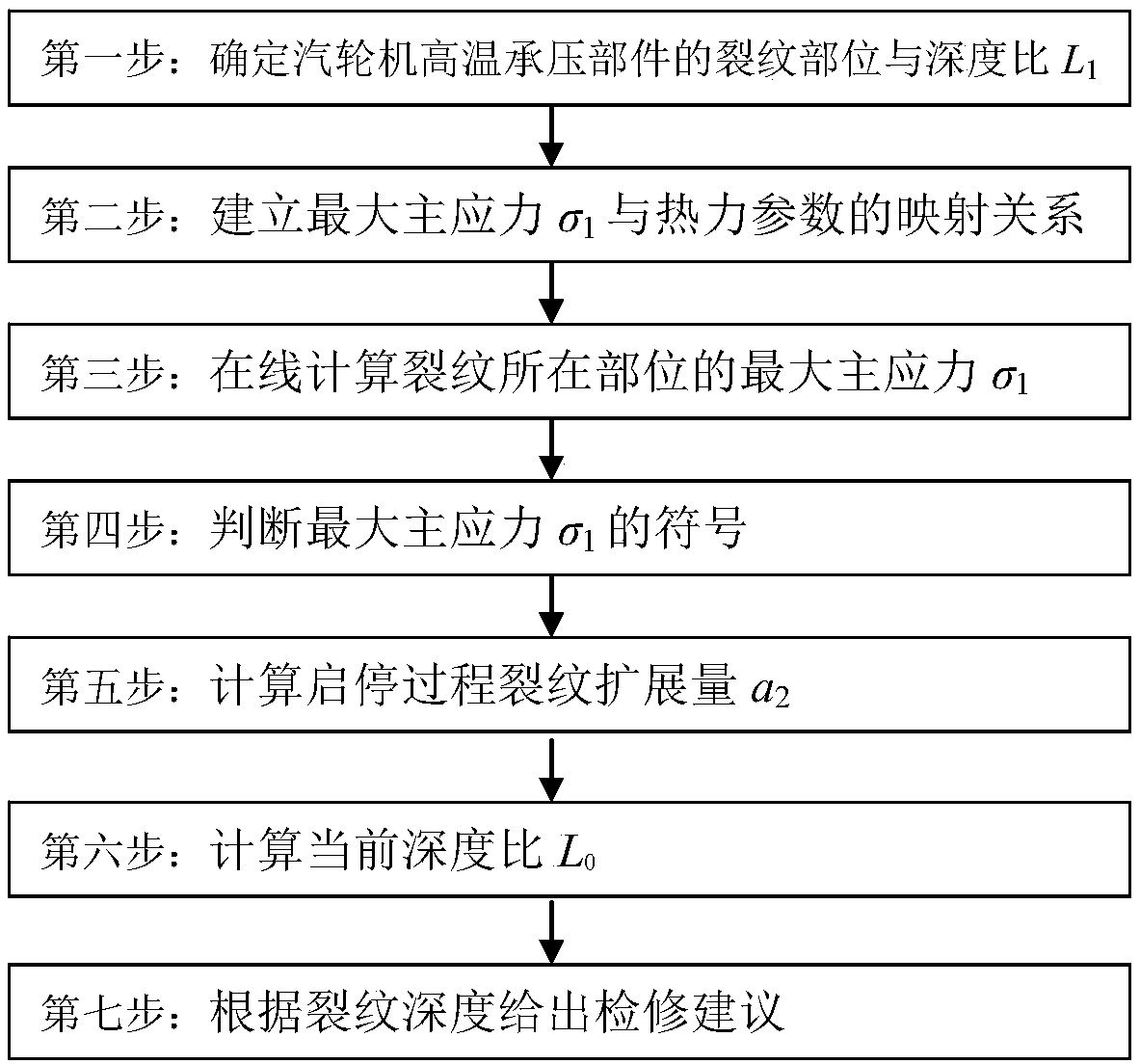

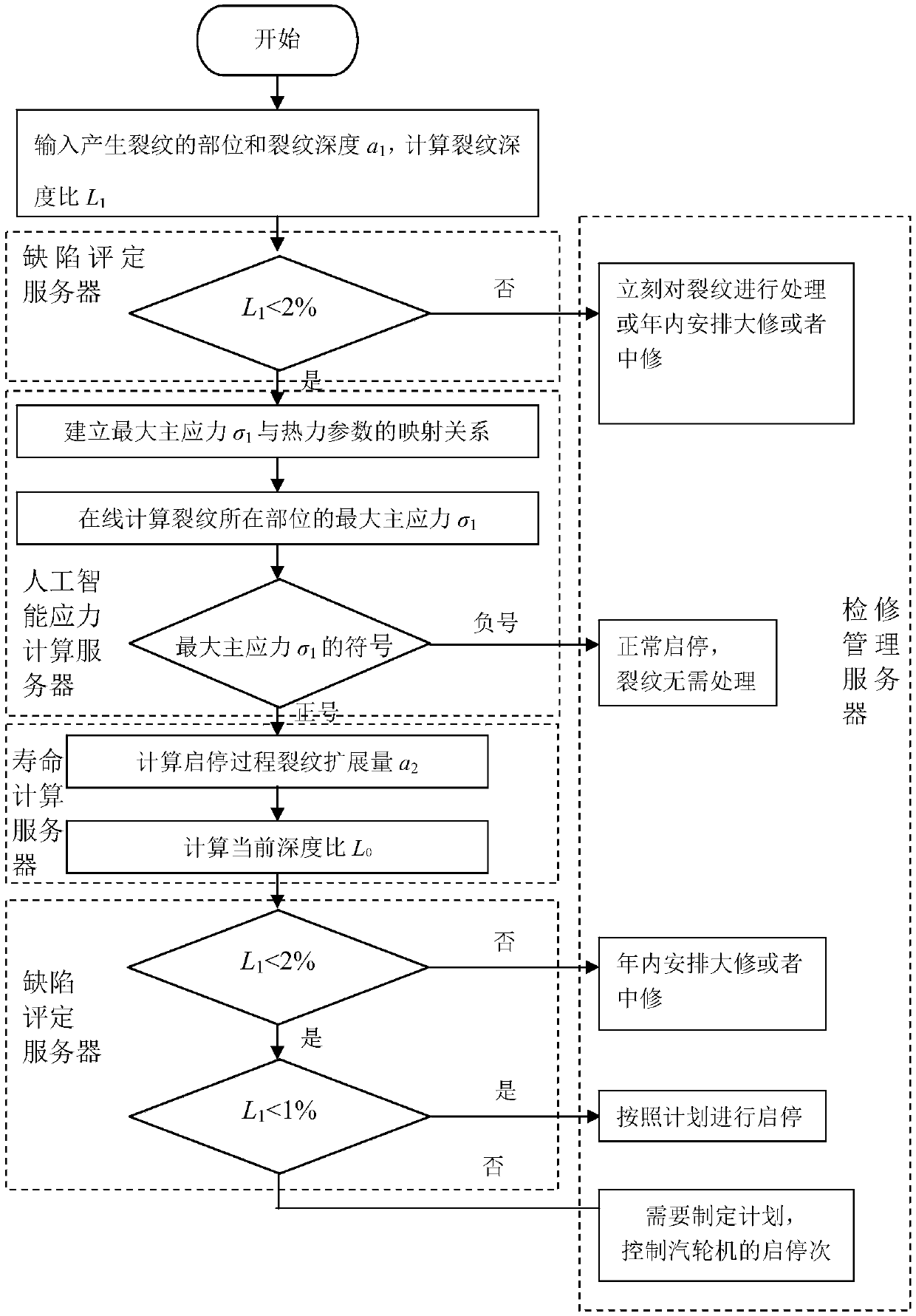

[0051] For a certain type of 600MW steam turbine high-pressure inner cylinder, the structure of the high-pressure inner cylinder is as follows Figure 4 As shown, during the service period of the 600MW steam turbine, the figure 1 the device shown, figure 2 The flow chart shown and image 3 As shown in the computer software, during the overhaul process, it is found that there is a crack with a depth of 0.5mm at part A, where the wall thickness of the inner cylinder is 320mm.

[0052] Step 1: Determine the depth ratio L of the high-pressure cylinder of the steam turbine 1 , Will L 1 The value of is entered into the database server;

[0053] Step 2: Online calculation of the maximum principal stress σ at the crack location 1 :

[0054] Using the recommended start-stop curve provided by the manufacturer and the actual start-stop curve of the power plant, establish σ 1 The mapping relationship with main steam temperature, main steam temperature and pressure, reheat steam ...

Embodiment 2

[0056] For a certain type of 660MW steam turbine high-pressure main steam valve and regulating valve casing, the structure of the high-pressure valve casing is as follows Figure 5 As shown, during the service period of the 660MW steam turbine, the figure 1 the device shown, figure 2 The flow chart shown and image 3 As shown in the computer software, during the overhaul process, it is found that there is a crack with a depth of 1mm at part C, where the wall thickness of the inner cylinder is 138mm.

[0057] Step 1: Determine the depth ratio L of the high-pressure cylinder of the steam turbine 1 , Will L 1 The value of is entered into the database server;

[0058] Step 2: Online calculation of the maximum principal stress σ at the crack location 1 :

[0059] Using the recommended start-stop curve provided by the manufacturer and the actual start-stop curve of the power plant, establish σ 1 The mapping relationship with main steam temperature, main steam temperature a...

Embodiment 3

[0066] For a certain type of 350MW steam turbine thin-walled medium-pressure inner cylinder, the structure of the medium-pressure inner cylinder is as follows Figure 6 As shown, during the service period of the 350MW steam turbine, the figure 1 the device shown, figure 2 The flow chart shown and image 3 As shown in the computer software, during the overhaul process, it is found that there is a crack with a depth of 1.7mm at part E, where the wall thickness of the inner cylinder is 88.5mm.

[0067] Step 1: Determine the depth ratio L of the high-pressure cylinder of the steam turbine 1 , Will L 1 The value of is entered into the database server;

[0068] Step 2: Online calculation of the maximum principal stress σ at the crack location 1 :

[0069] Using the recommended start-stop curve provided by the manufacturer and the actual start-stop curve of the power plant, establish σ 1 The mapping relationship between main steam temperature and pressure, reheat steam temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com