Detection device for engine crankshaft

A detection device and engine technology, applied in the direction of engine testing, measuring devices, machine/structural component testing, etc., can solve problems such as unfavorable crankshaft quality, control, and inability to effectively respond to crankshaft quality, and achieve compact structure and improved accuracy , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

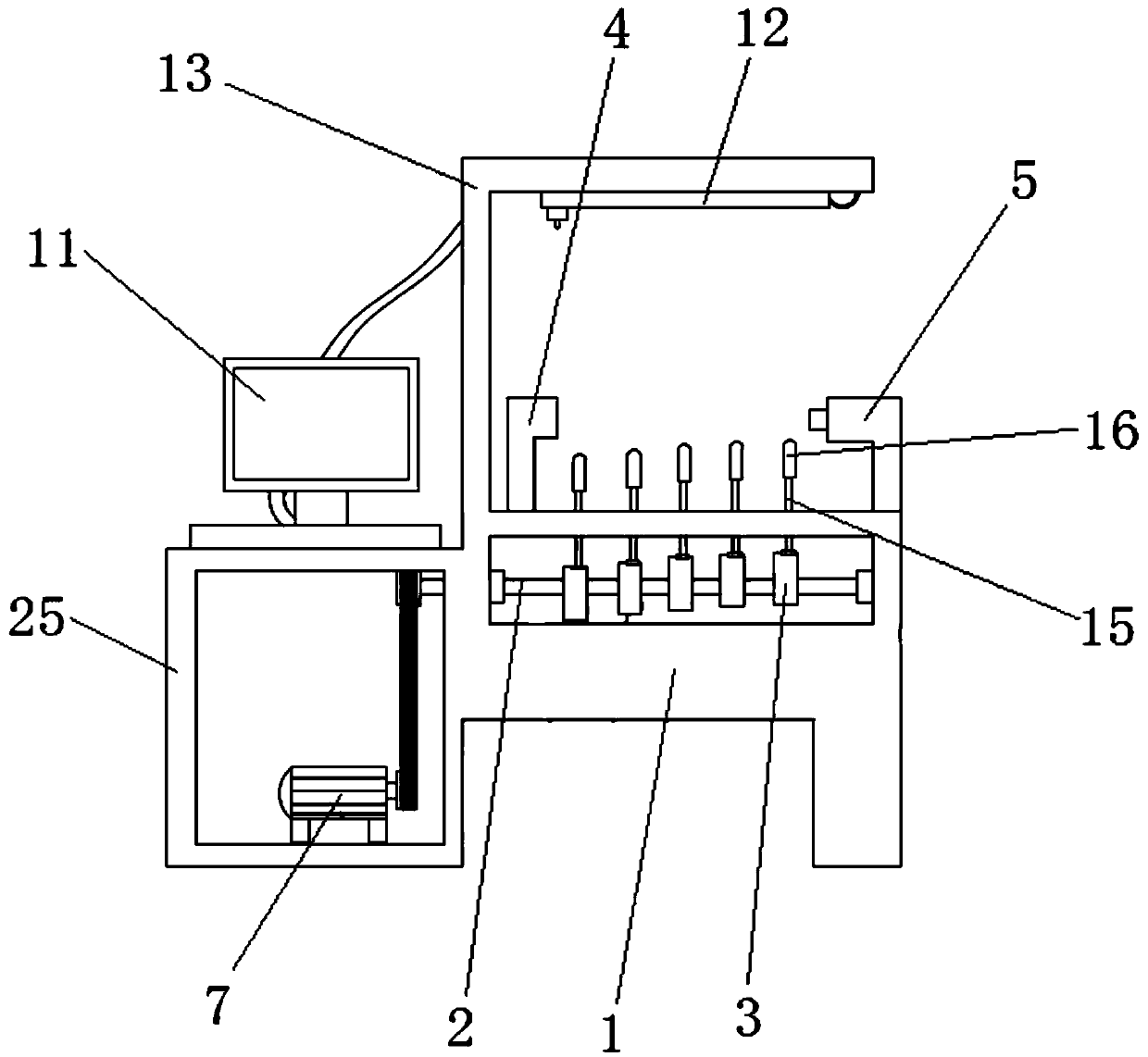

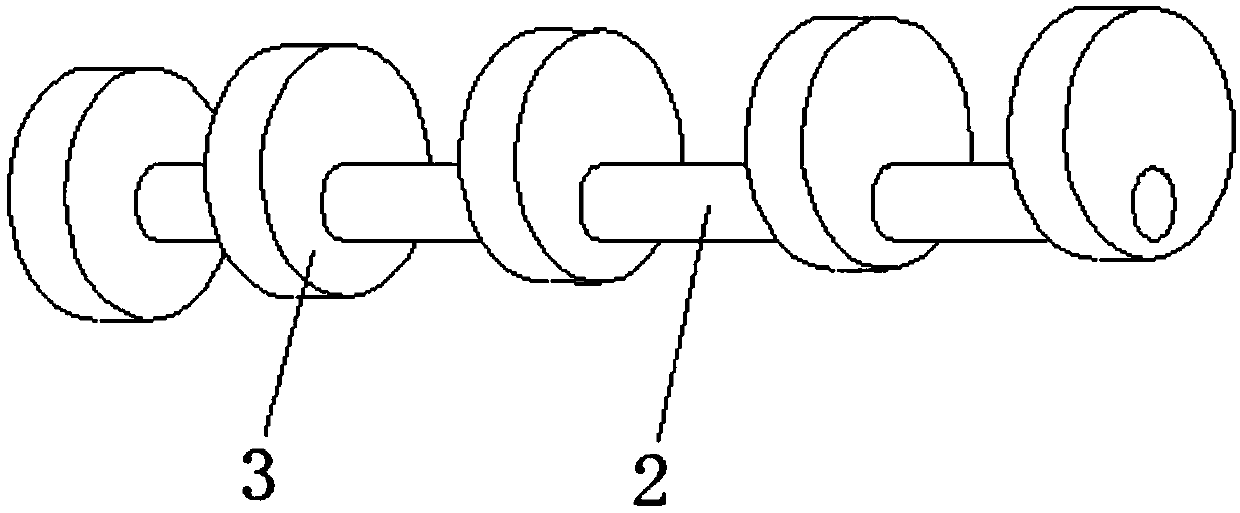

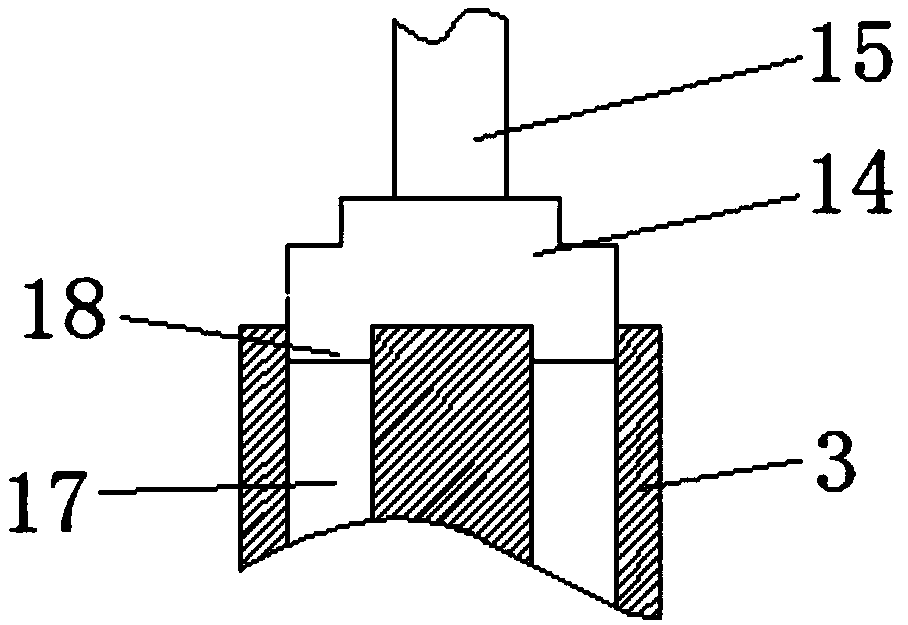

[0023] refer to Figure 1-5 As shown, a detection device for an engine crankshaft of the present invention includes a detection platform 1 and a detection assembly, wherein the detection platform 1 is provided with a mounting bracket for installing the crankshaft, and the detection platform 1 is provided with a rotating rod 2, and the rotating rod 2 It is installed in the detection table 1 through the bearing rotation, and the rotating rod 2 is provided with a plurality of disks 3 arranged spirally and equidistantly along its axial direction. The number of the disks 3 is the same as that of the crankshaft journal, and the arrangement of the disks 3 The arrangement is the same as that of the crankshaft journal, each disk 3 is connected to the journal of the crankshaft through a connecting assembly, and a driving assembly 7 connected to the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com