Constrained predictive hybrid fault-tolerant control method for multi-stage batch process based on 2d model

A fault-tolerant control and predictive control technology, applied in adaptive control, general control system, control/regulation system, etc., can solve the problem of unadjustable controller gain, achieve optimal control performance, improve control quality, and shorten running time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

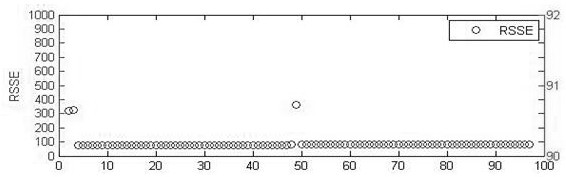

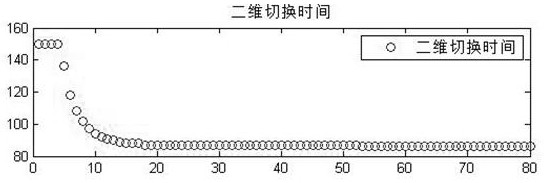

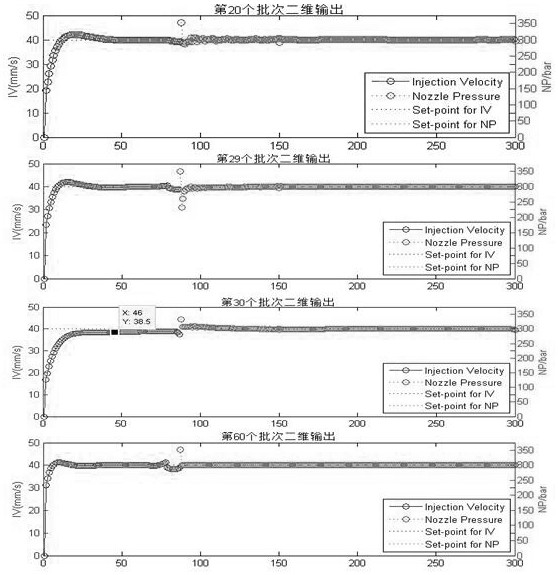

[0150] The invention takes the injection molding process as a representative to carry out the experiment of fault-tolerant control of the intermittent process in multi-stages with actuator faults. Each batch of the injection molding process mainly includes three processes: an injection section, a pressure holding section, and a cooling section. Among them, the control effect of the injection section and the pressure-holding section will have a direct impact on the final quality of the finished product, especially the injection speed in the injection section and the cavity pressure in the pressure-holding section have the greatest influence on the control effect of the corresponding stage, and errors are prone to occur , leading to bad products, we need to control the tracking value to ensure good tracking effect. The cooling section only cools high-temperature products without any control measures, and the present invention does not involve the research of the cooling section. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com