Empty tray recovery mechanism

A technology of recycling mechanism and empty pallets, applied in conveyors, object stacking, transportation and packaging, etc., can solve the problems of manual collection and low pallet recycling efficiency, and achieve the effect of ensuring recycling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

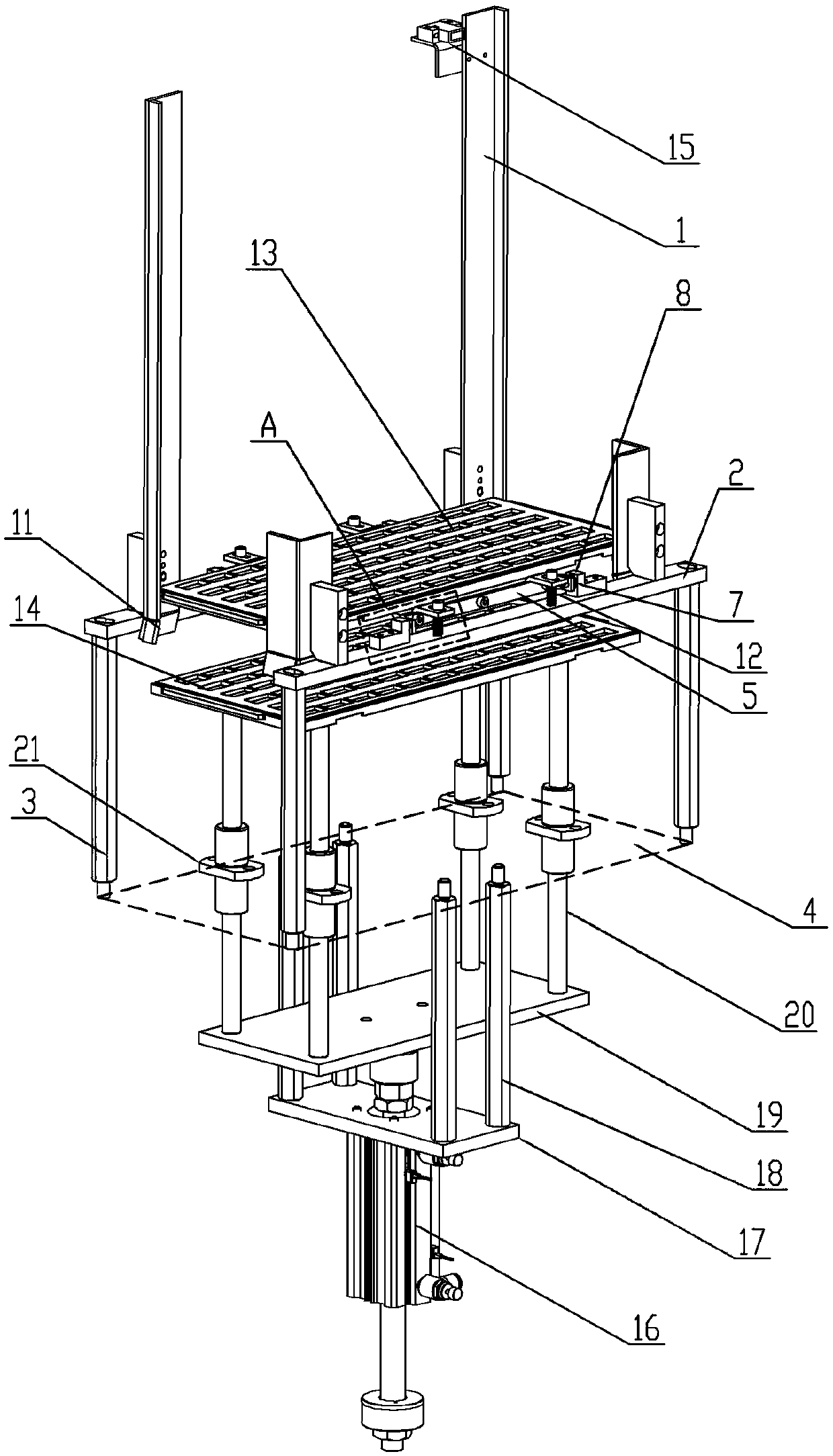

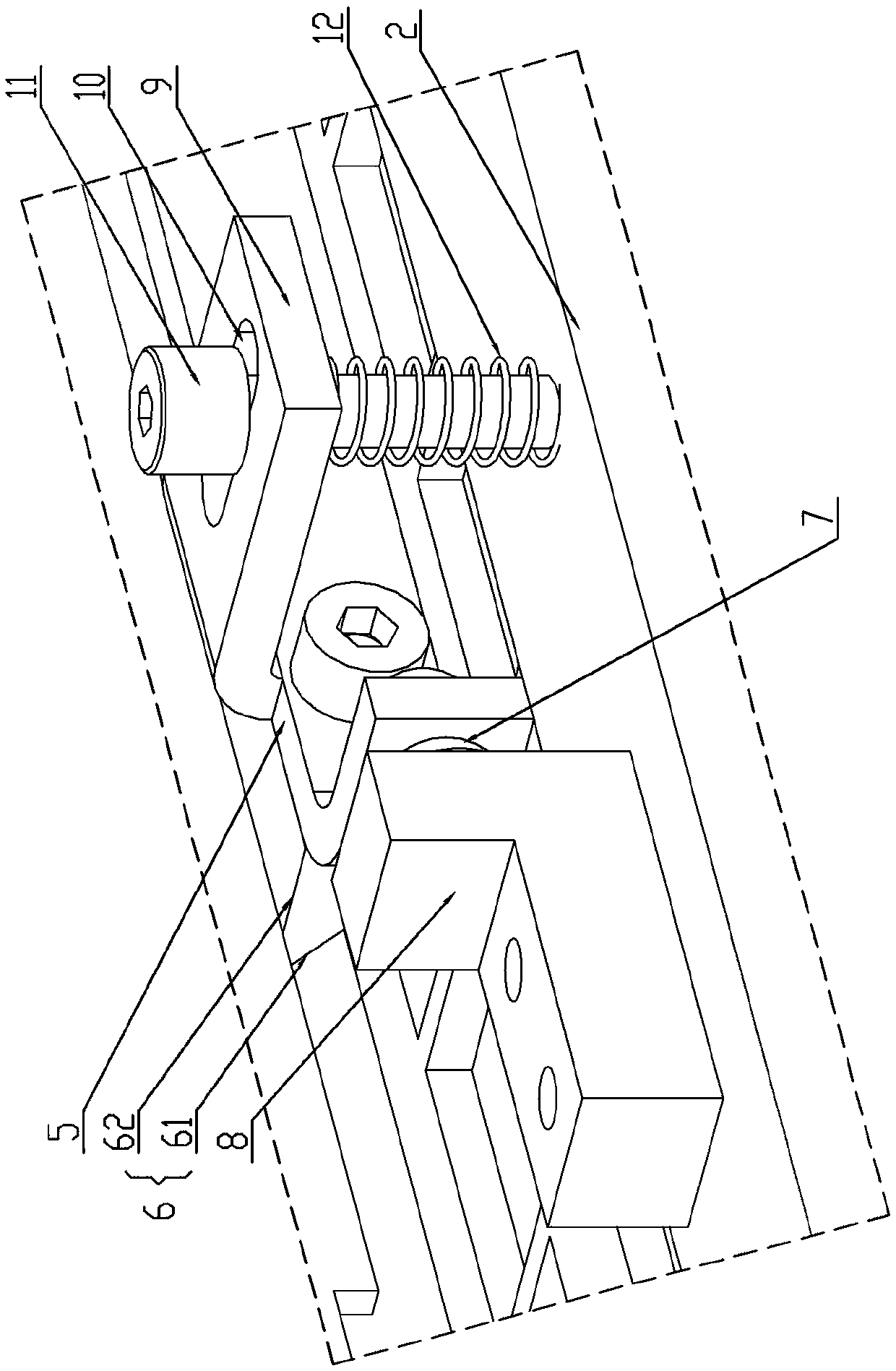

[0014] Empty pallet return mechanism, see figure 1 : It includes four guide frame bars 1 vertically limited, the bottoms of two sets of parallel guide frame bars 1 are respectively provided with independent bottom beams 2, two groups of bottom beams 2 are arranged in parallel, and the length direction of each bottom beam 2 The two ends are fixedly connected to the fixed mounting plate 4 through the fixed support rod 3 of the pallet bearing plate respectively, and the upper surface of the bottom cross beam 2 is provided with a tray carrier 5, and the support rods 6 of the two pallet carrier 5 are arranged opposite to each other, and each support rod 6 Including the bottom transition slope 61 and the upper horizontal stop plane 62, the two ends of the length direction of the tray carrier 6 are installed on the corresponding installation protrusions 8 of the bottom beam 2 through the rotating shaft 7, and the length direction of the tray carrier 5 corresponds to the bottom beam 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com