Truss folding type hydraulic flip plate

A folding and truss technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of high manufacturing cost, vehicle rollover, poor synchronization, etc., achieve convenient operation, improve safety and reliability, and solve synchronization problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

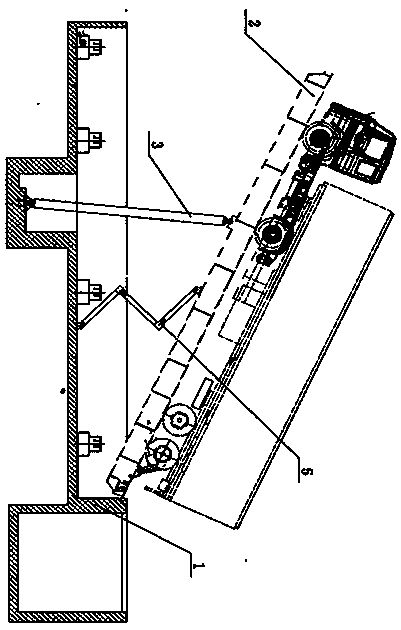

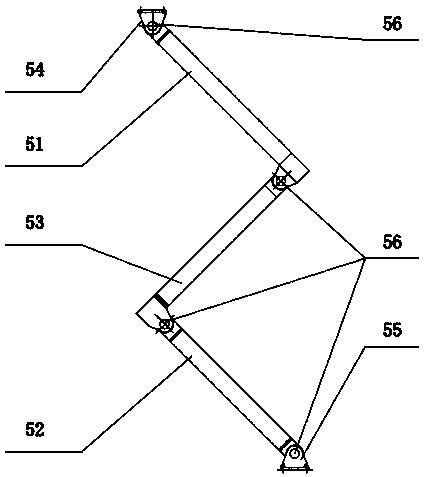

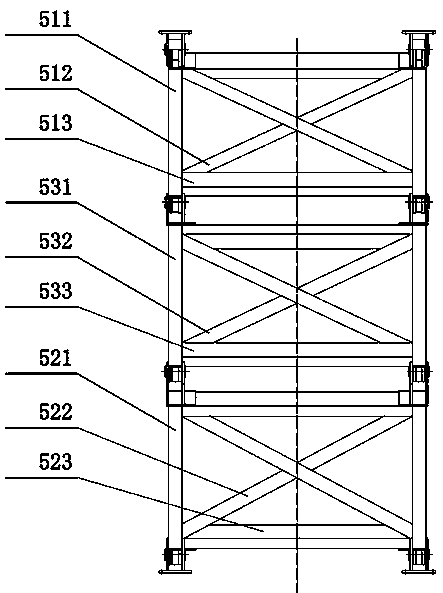

[0013] refer to figure 1 , figure 2 and image 3 , a preferred embodiment of the present invention: the truss folding hydraulic flap includes a hydraulic flap support platform 2 hinged at one end to the base 1, a jacking mechanism 3 is provided below the hydraulic flap support platform 2, and the jacking mechanism 3 includes jacking cylinders arranged on both sides of the hydraulic flap support platform, one end of the jacking cylinder is movably connected with the hydraulic flap support platform 2, and the other end is movably connected with the base 1, and the hydraulic flap support platform 2 is movably connected. A truss folding self-synchronizing system 5 is also provided, and the truss folding self-synchronizing system 5 is arranged at the lower part of the hydraulic flap support platform 2, between the hinged end of the base 1 and the jacking mechanism 3; the truss folding self-synchronizing system 5 System 5 includes an upper truss 51, an intermediate truss 53, a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com