Scraper apparatus capable of cleaning dryer by scraping waste through rotary-type spinning bracket during papermaking

A scraper device and rotary technology, applied in the field of papermaking, can solve problems such as imperfect equipment and difficult scraping of paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

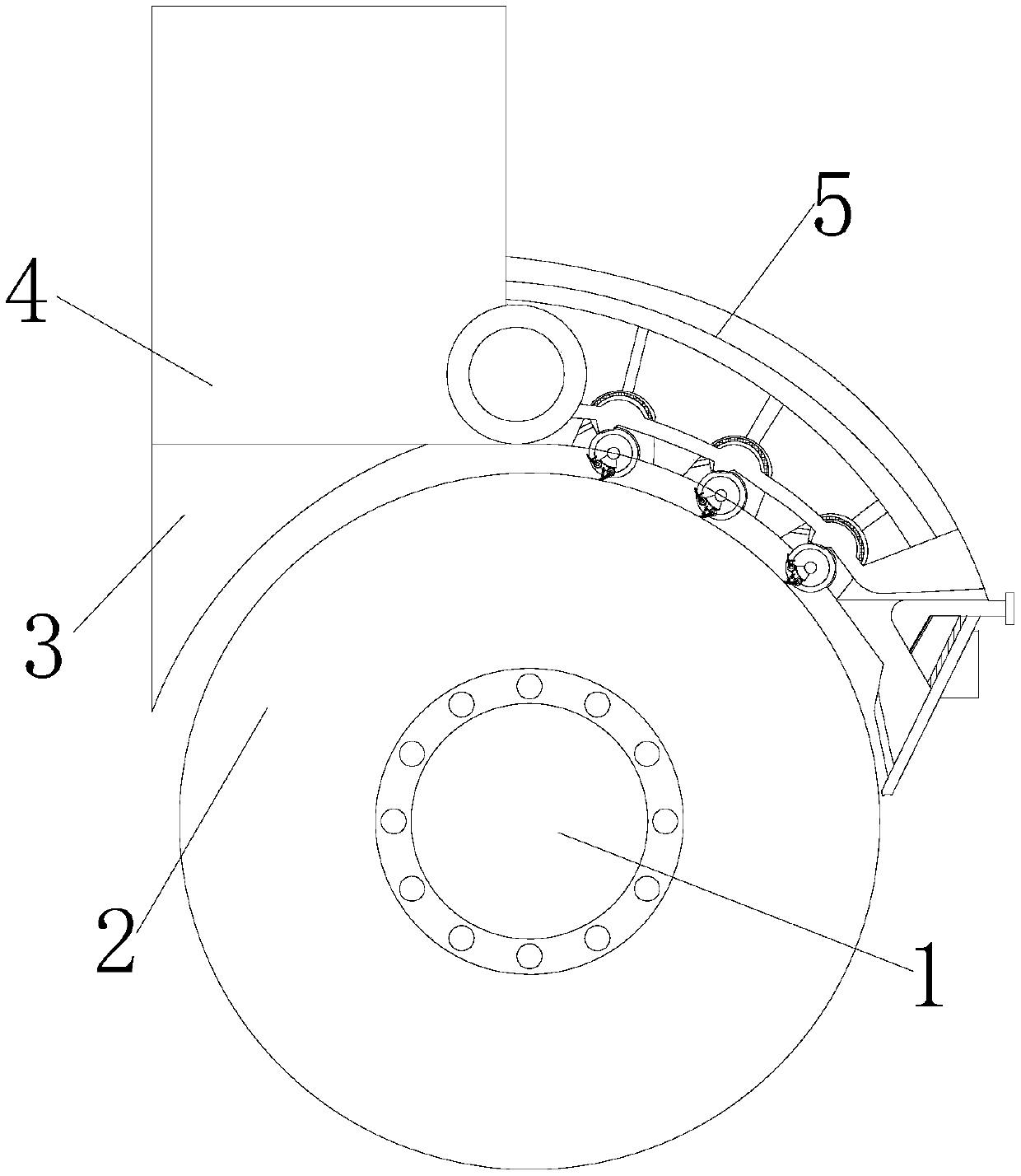

[0027] see figure 1 , the present invention provides a scraper device used to clean the drying cylinder when scraping the papermaking by rotating the swing-out bracket. The bearing 1 is located on the outer end face of the dryer wheel 2 and at the same time cooperates with the dryer wheel 2 through the rod body fit clearance, and the said matching output device 5 is movably installed and attached to the outer end face of the dryer wheel 2 through the wheel body in a surface contact manner. The support seat 4 is located on the right side surface of the matching output device 5 and is hingedly connected with the matching output device 5 by a movable rod. The inclined plate 3 and the support seat 4 are perpendicular to each other and are connected together by welding. The outer end surface of the cylinder wheel 2 is a smooth cylindrical movable structure, and the smooth cylindrical body can prevent wrinkles from appearing in the paper when drying.

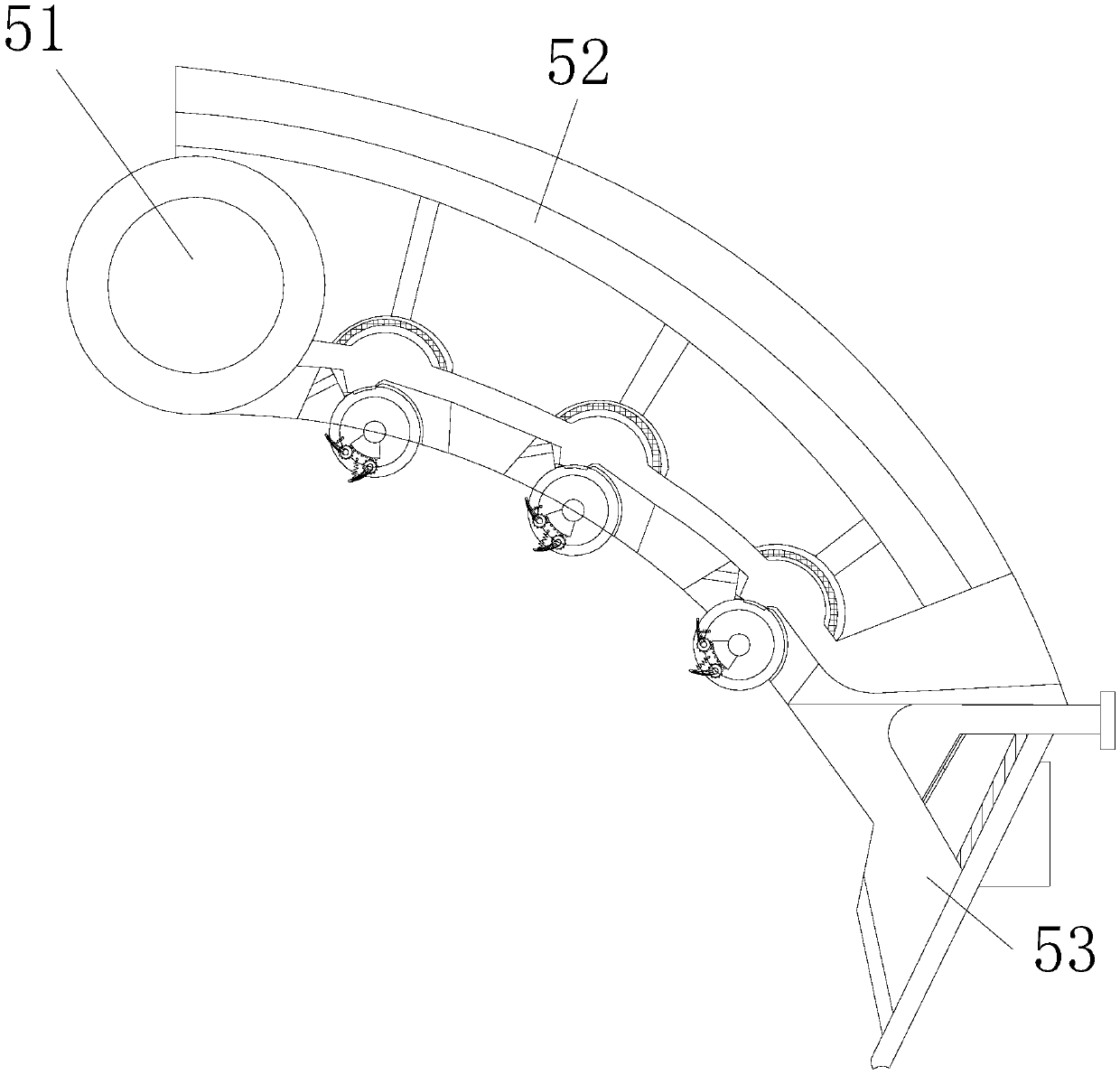

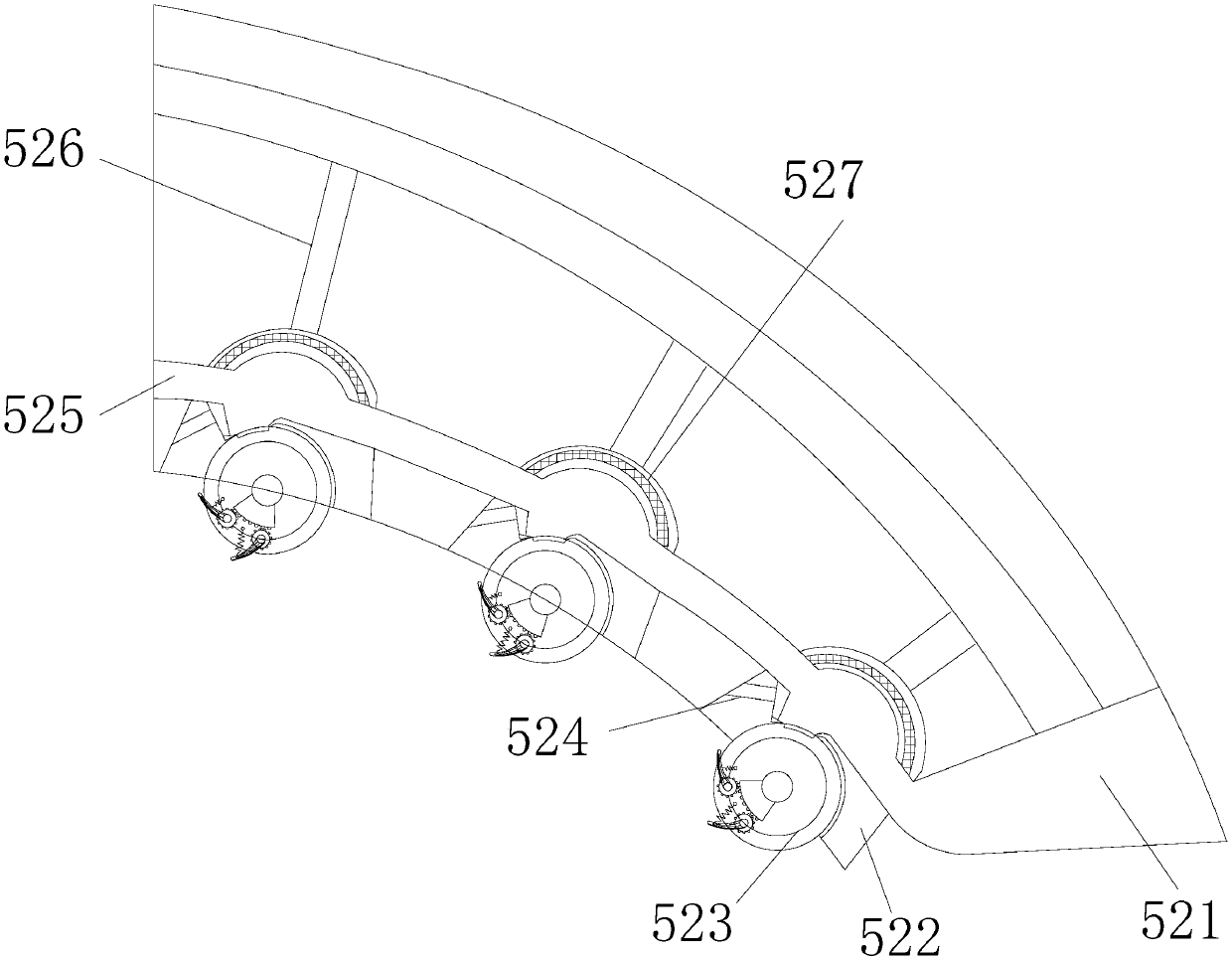

[0028] see figure 2 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com