Intelligent detection method for wood optimizing cut-off saw based on deep learning

A detection method and deep learning technology, which are applied in optical testing flaws/defects, material analysis by optical means, measuring devices, etc., can solve the problems of accurate position recognition deviation of wood, unautomated production, visual fatigue, etc., and achieve automation The effect of high degree, improved automation level and strong fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

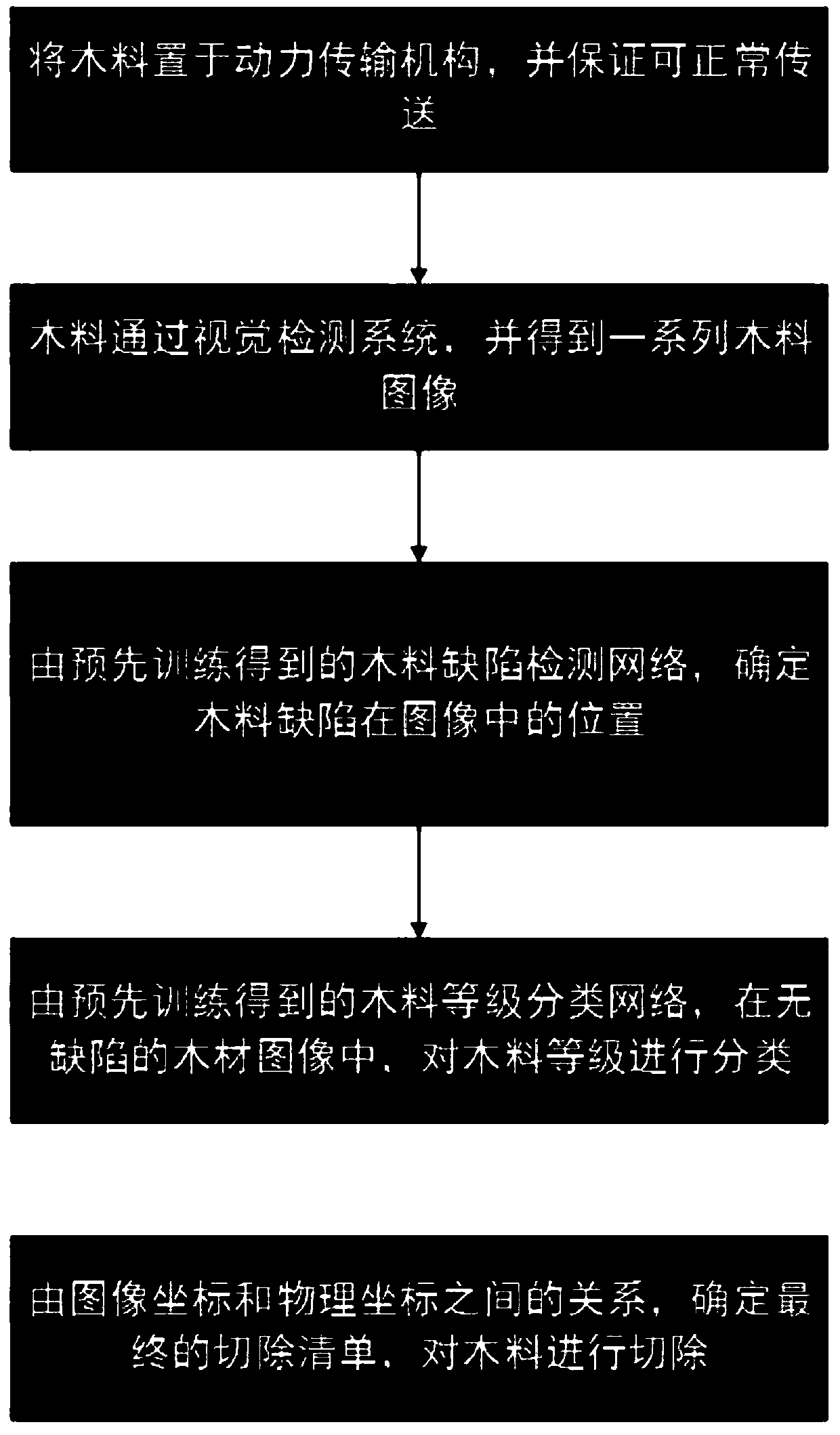

[0025] A preferred saw intelligent detection method based on deep learning, its specific implementation steps are as follows:

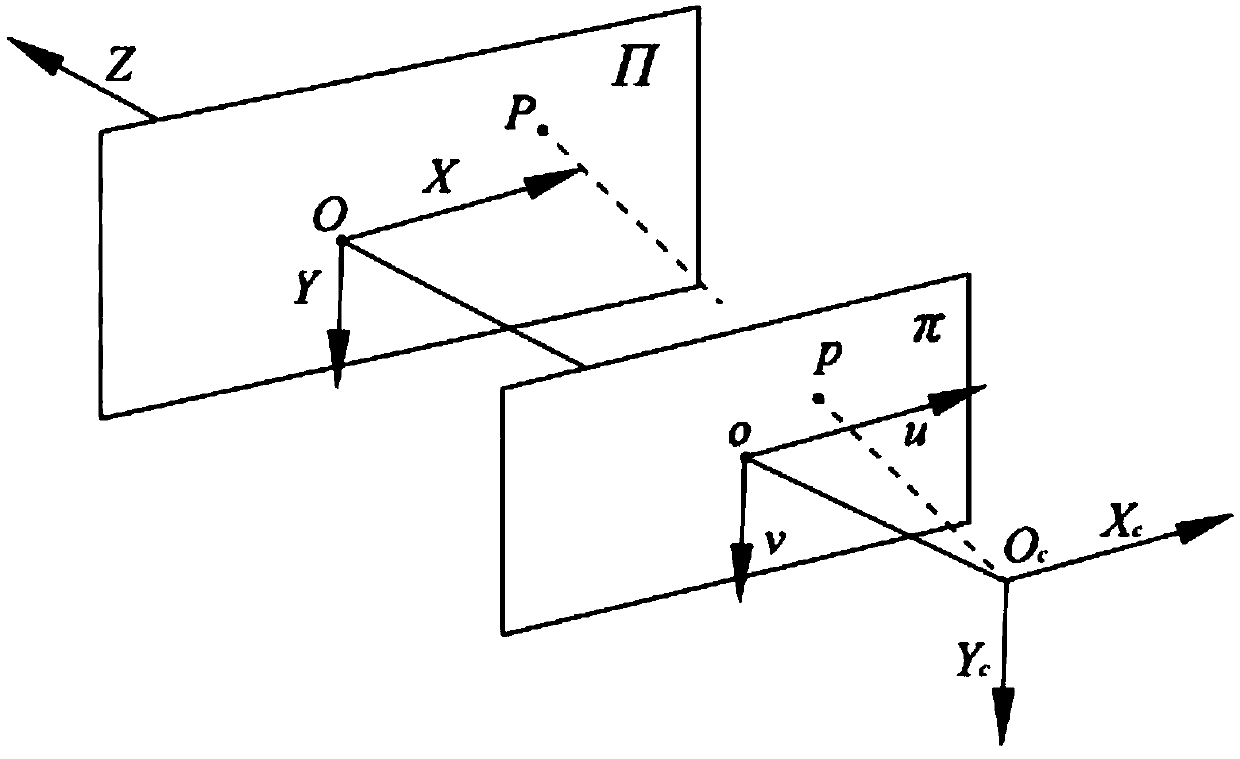

[0026] (1) The relationship between image coordinates and physical coordinates

[0027] Oc-XcYcZc is the camera coordinate system, o-uv is the image coordinate system ( figure 2 ). In the camera coordinate system, the camera origin and optical axis are the Z axis of the camera coordinate system. A point P in the space plane Π is projected into the image plane π, a world coordinate system is established in the space plane Π, and the homogeneous coordinates of point P are defined as P=(X W ,Y W ,Z W ,1) T , the image homogeneous coordinates of the corresponding image points are p=(u,v,1) T , in perspective projection geometry, we can get the following relation:

[0028]

[0029] Among them, f x , f y ,u 0 ,v 0 is the internal parameter of the camera, R, t is the external parameter of the camera, and s is the coefficient. Assume

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com