Ultrasonic flaw detection method and device for upper arcs and lower jaw areas on both sides of rail head

A technology of ultrasonic flaw detection and flaw detection equipment, which is applied in measuring equipment, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., to ensure accuracy and reliability, prolong service life, The effect of meeting the sensitivity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

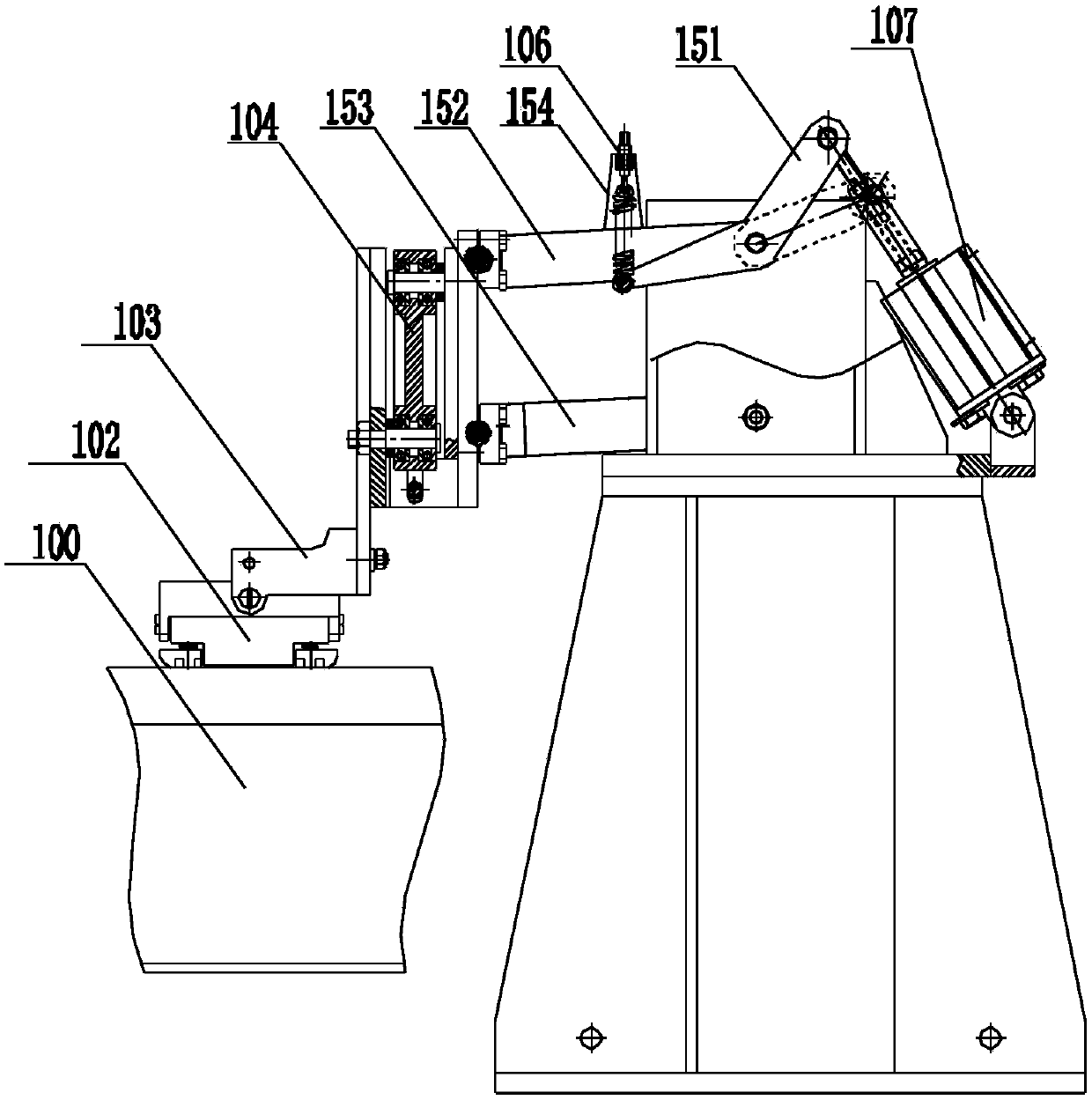

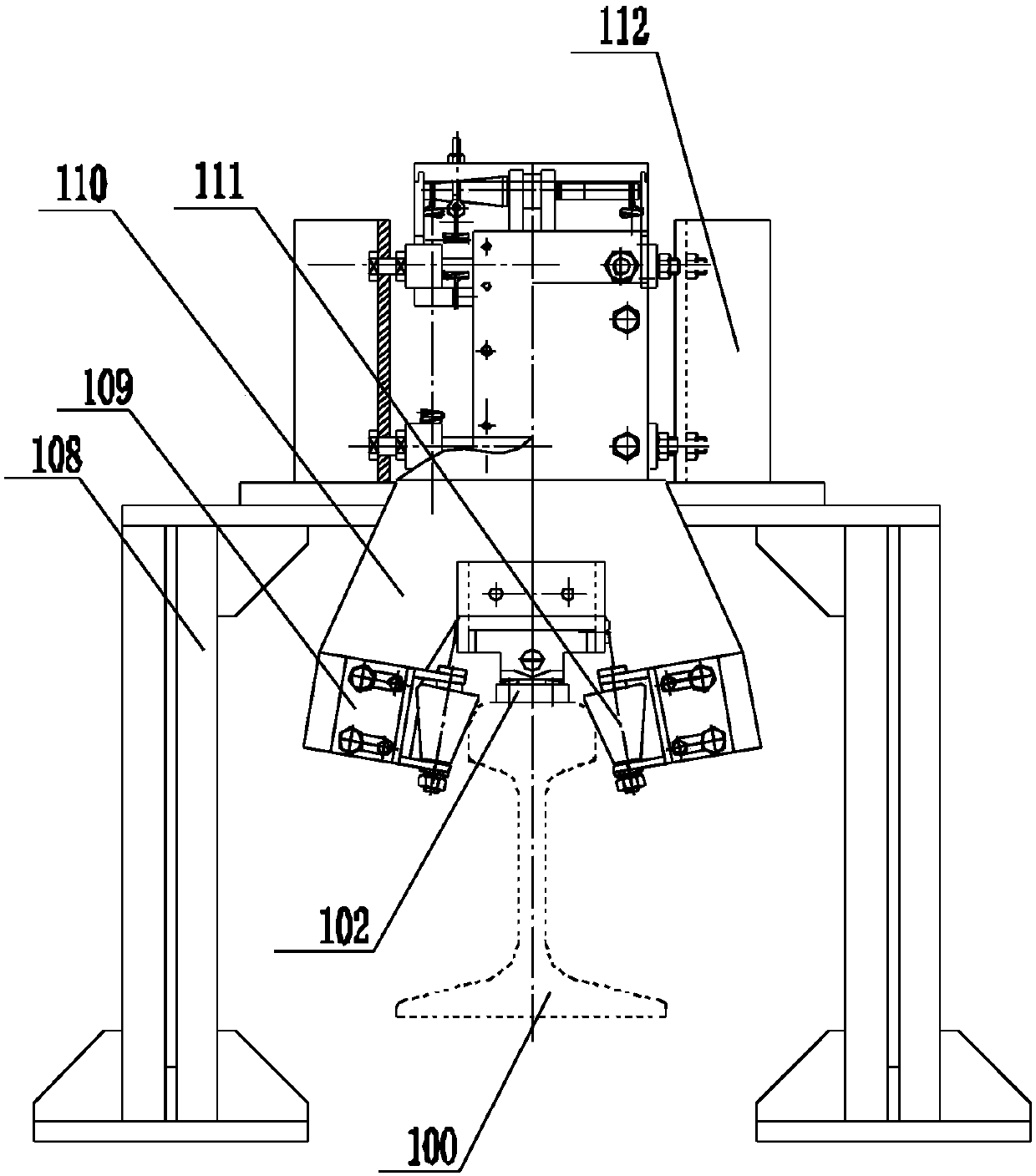

[0034] See Figure 1-Figure 10 , an ultrasonic flaw detection method for the upper arc and the lower jaw area on both sides of the rail head,

[0035] 1) Ultrasonic flaw detection of the lower jaw area of rail 100, see Figure 5 , Image 6 :

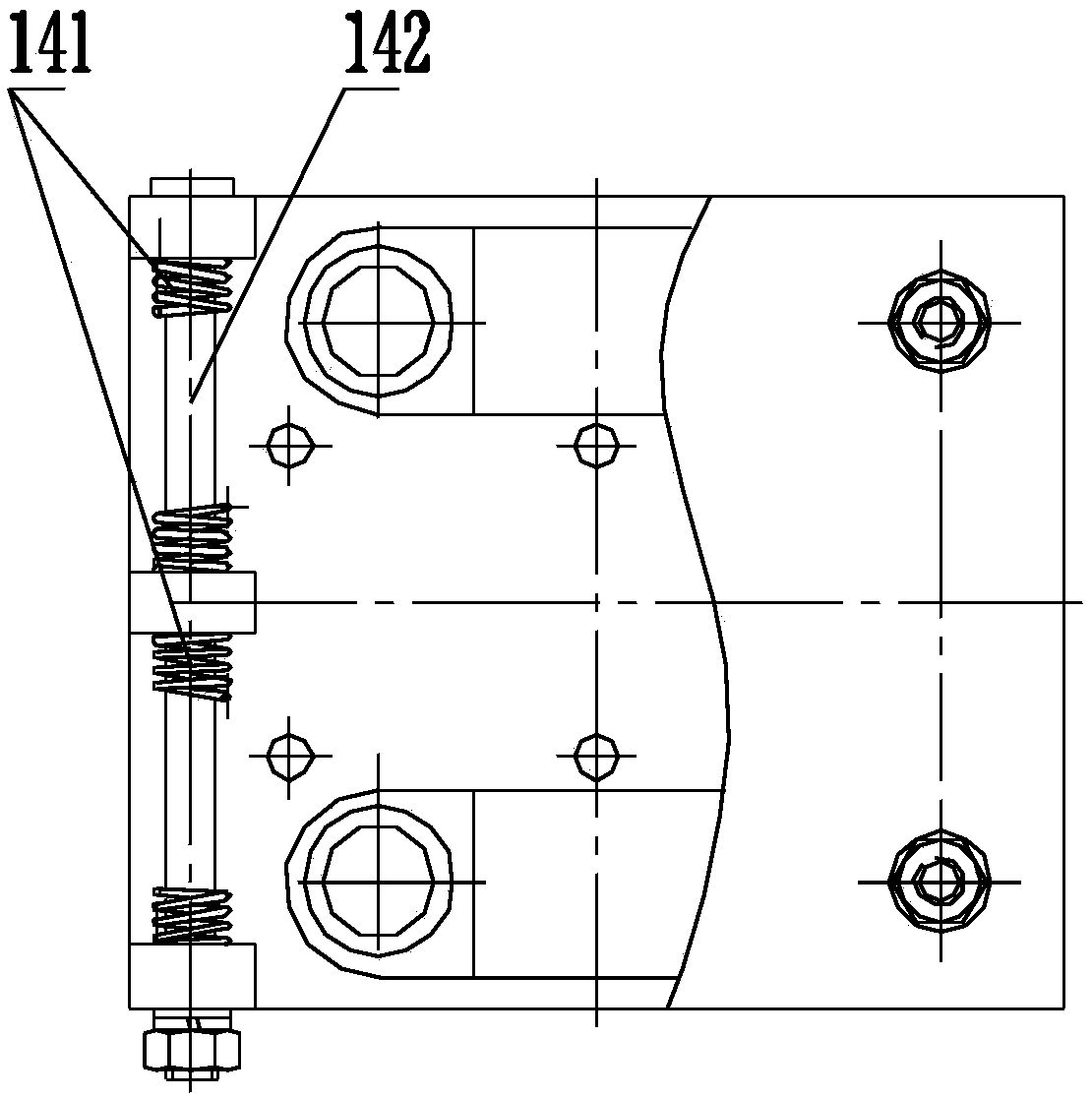

[0036] An artificial flat-bottomed hole defect 113 is respectively set in the mandible area on both sides above the running center line of the rail 100 to be tested, Figure 5 is the flat-bottomed hole defect set on the left, Image 6 The flat-bottomed hole defect is set on the right; the artificial flat-bottomed hole defect 113 set in the lower jaw area on both sides of the rail 100 is a ∮2mm flat-bottomed hole, the allowable deviation of the flat-bottomed hole diameter: ±0.1mm; the depth is 9mm, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com