Pneumatic vehicle tyre

A technology for pneumatic tires and vehicles, which is applied to off-road vehicle tires, vehicle parts, tire parts, etc., to achieve the effect of improving handling characteristics and braking characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

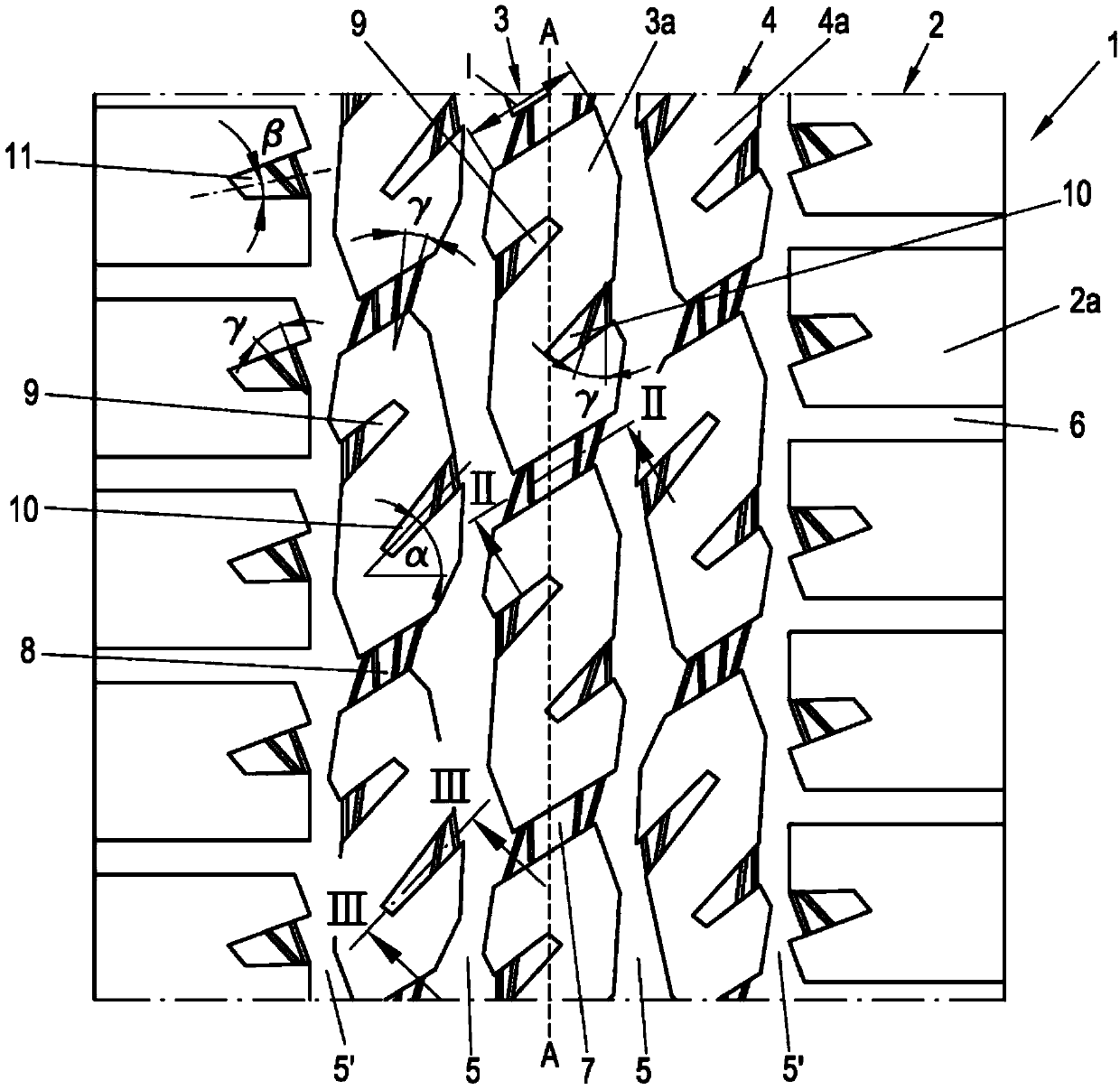

[0016] The present invention relates to a specific design of the tread 1 of a pneumatic tire for vehicles, equally suitable for off-road use and on-road use. Such tires are commonly known as all-terrain or off-road tyres, and their tread has a greater tread depth (in the range of 12mm) than conventional tires for passenger motor vehicles. In order for such tires to have good traction properties on unpaved ground, a greater tread depth is especially required.

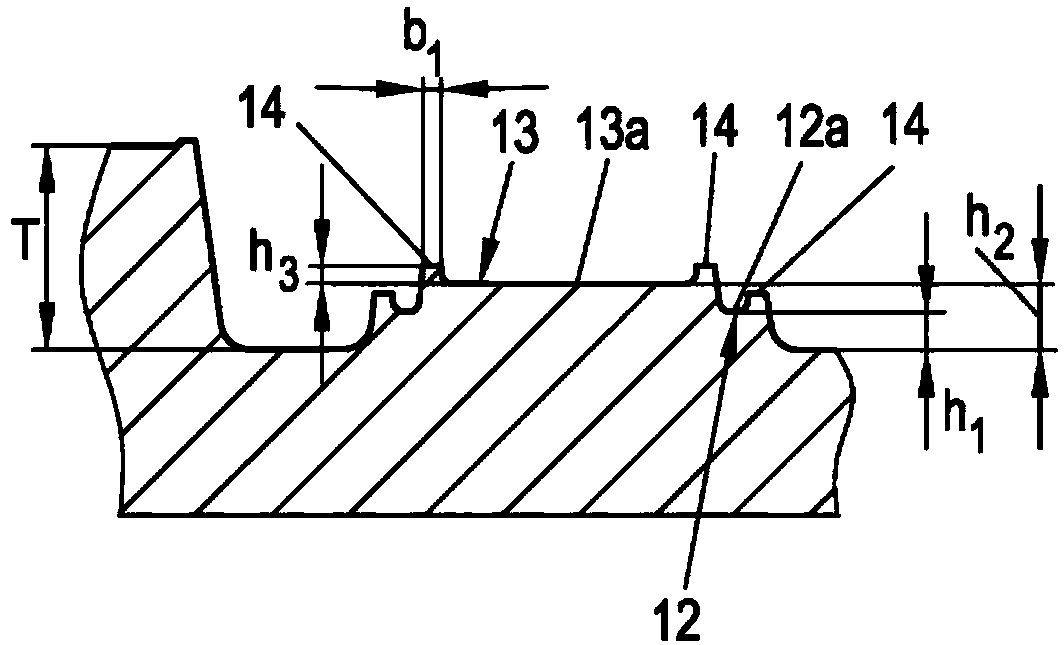

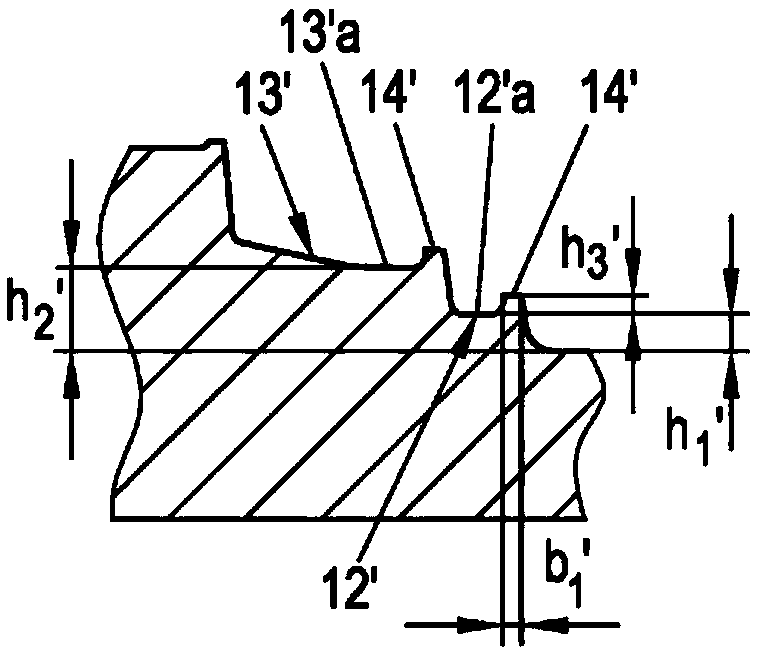

[0017] In the following description as well as in the patent claims, the angles specified in the context of a groove relate to the center line or direction of extension of said groove. All heights are measured along the radial direction.

[0018] figure 1 The tread 1 shown in has a pronounced block structure with in each case a shoulder row of blocks 2, a central row of blocks 3 extending along the center line of the tire (line A-A), and arranged in Two middle block rows 4 between the central block row 3 and the shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com