Coupling bionic driving wheel capable of improving traction force of wheel type tractor

A tractor and traction force technology, applied in the field of wheel tractors and coupling bionic drive wheels, can solve the problems of inability to guarantee the working efficiency of the tractor, easy wear strength of conical and triangular prism-shaped tines, and insufficiency. Barrier ability and debonding ability, good traction characteristics, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

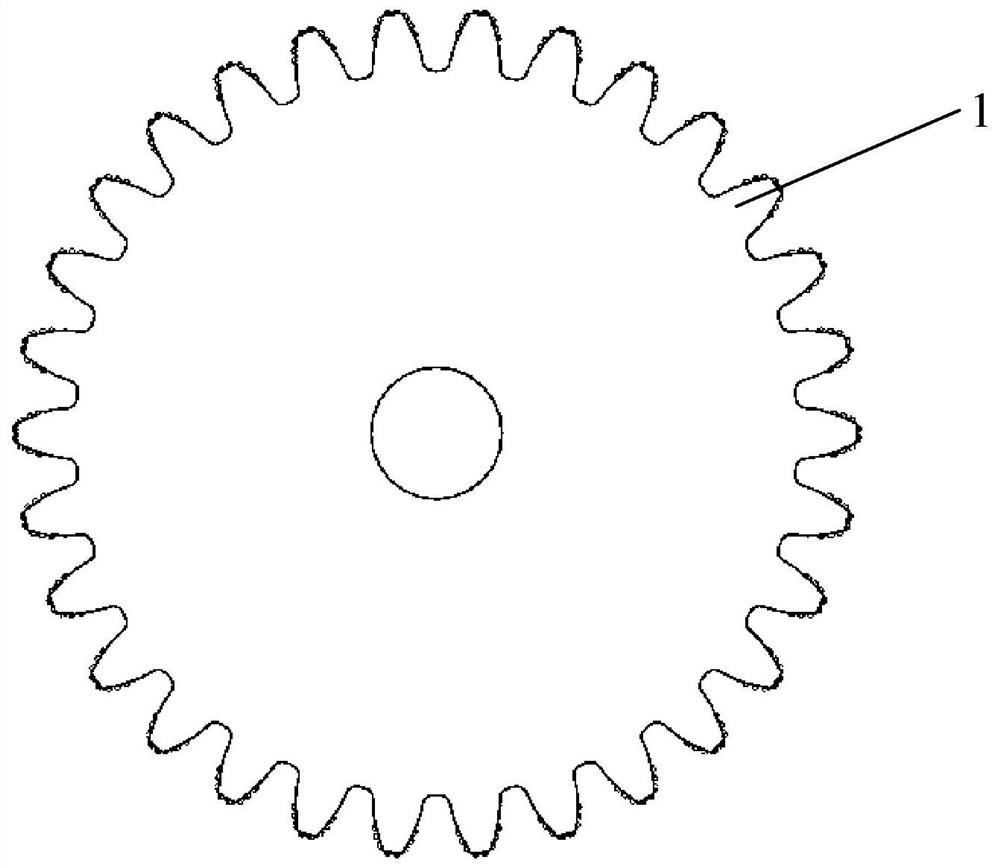

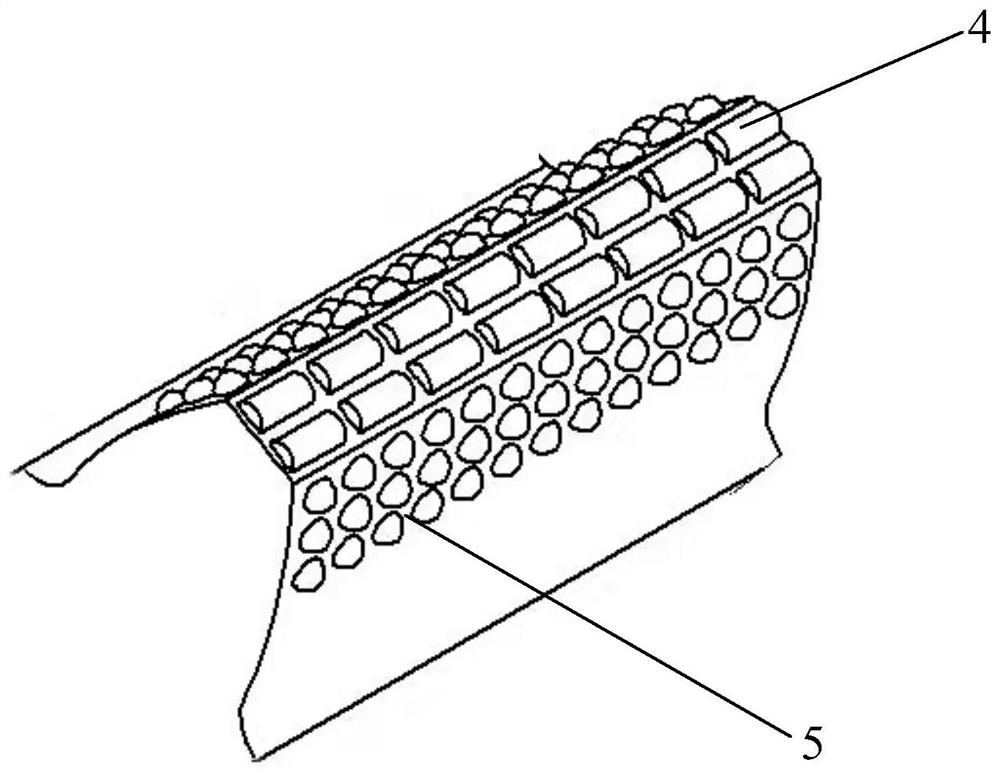

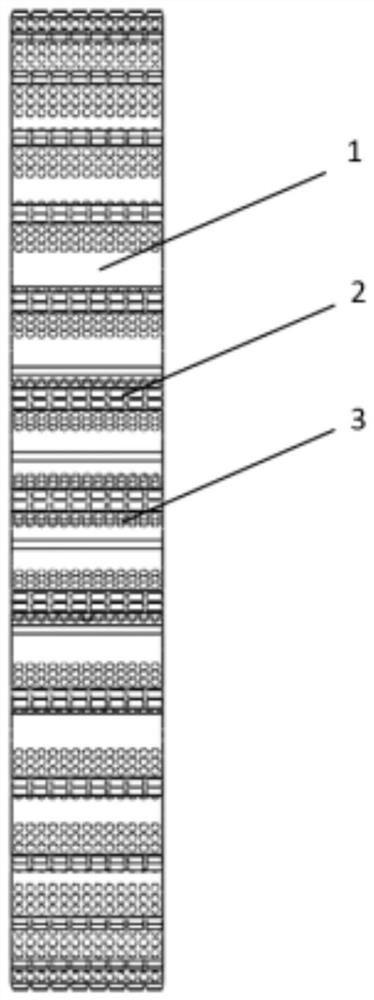

[0036] The invention provides a coupling bionic driving wheel which can improve the traction force of a wheeled tractor. The tooth surface of its gear teeth 1 is processed with a protruding structure imitating the surface topography of clam and clam shells; the protruding structure includes The cylindrical coupling body structure 2 on the top surface of the gear tooth 1, the convex spherical coupling body structure 3 located on the two sides of the gear tooth 1, the cylindrical coupling body structure 2 includes a plurality of columnar units 4 arranged in an array , the convex ball coupling body structure 3 includes a plurality of convex balls 5 arranged in an array.

[0037] It needs to be emphasized that the purpose of designing the convex spherical coupling body structure 3 on both sides of the gear teeth is: ① When the convex spherical coupling body structure 3 is over the step obstacle at the pipe coupling, see Figure 4 , on the one hand, the friction coefficient is incr...

Embodiment 2

[0047] see Figure 1-3 As shown, the bionic drive wheel coupled with the wheeled tractor provided by the present invention includes 30 gear teeth 1, and 39 convex balls 5 are respectively arranged on the side of each gear tooth 1, and are embedded in the wheel in three parallel rows in the axial direction. On the side of the tooth 1, 16 columnar units 4 are arranged on the top surface of each tooth 1, and are embedded in the top surface of the tooth 1 in parallel and evenly distributed in two axial rows. Specifically, the diameter of the coupled bionic drive wheel is 60mm, and the modulus is 2; wherein, the diameter of the convex balls 5 is 0.6mm, the size of the columnar unit 4 is Φ0.6×1mm, and the balls of the adjacent convex balls 5 The center distance is 1 mm, and 16 columnar units 4 are arranged in rows and columns on the top surface of the tooth. The distance between adjacent columnar units 4 in the same column is 0.3 mm, and the distance between adjacent columnar units ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com