Single disc half torus type continuously variable transmission

A continuously variable transmission, semi-toroidal technology, applied in the direction of gear transmission, friction transmission, belt/chain/gear, etc. Difficulties, high manufacturing precision of transmission components, to achieve the effect of improving traction characteristics, simple and reliable speed regulation, and convenient speed regulation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

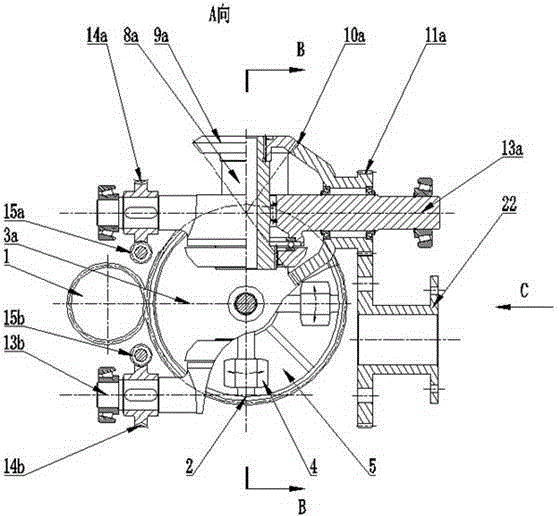

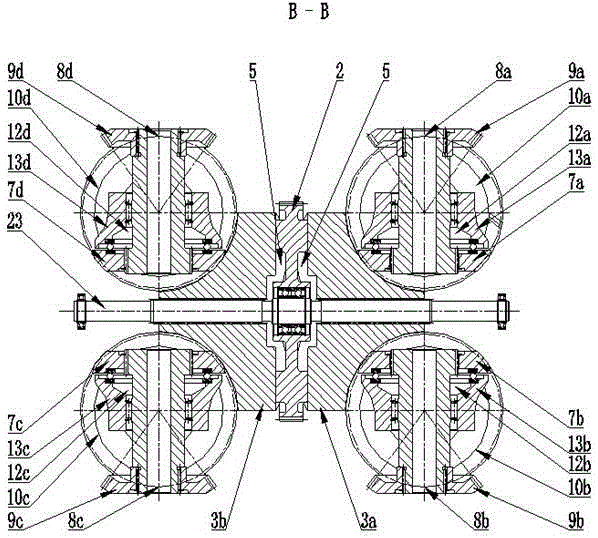

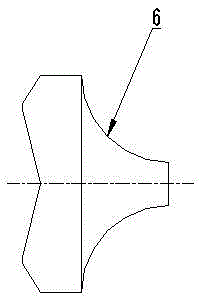

[0023] Such as figure 1 , image 3 , Figure 4As shown, the loading cam gear (2) is installed on the central shaft (23), with rolling bearings installed in the middle, and the input disc A (3a) and input disc B (3b) are also installed on the central shaft (23) and connected by splines. And installed symmetrically on both ends of the loading cam gear (2); the mandrel A (13a) and the mandrel A (13b) are symmetrically installed around the input disc A (3a) on one side, and the input disc B on the other side ( 3b) There are also spindles C (13c) and D (13d) installed symmetrically around them. There are four spindles in the entire continuously variable transmission: spindle A (13a), spindle B (13b), spindle C ( 13c), mandrel D (13d), they are distributed symmetrically, and their center lines respectively coincide with the center of the projected circle of the input disc annulus (6) in the front view; mandrel A (13a), mandrel B (13b) Cavity A (12a), Cavity B (12b), Cavity C (12c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com