Tool rapidly correcting cylindrical workpiece

A technology for cylindrical parts and tools, which is applied in the field of rapid calibration of cylindrical parts and tools, can solve the problems of complex calibration process, low work efficiency, high production cost, etc., and achieve the effect of convenient cylinder calibration, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

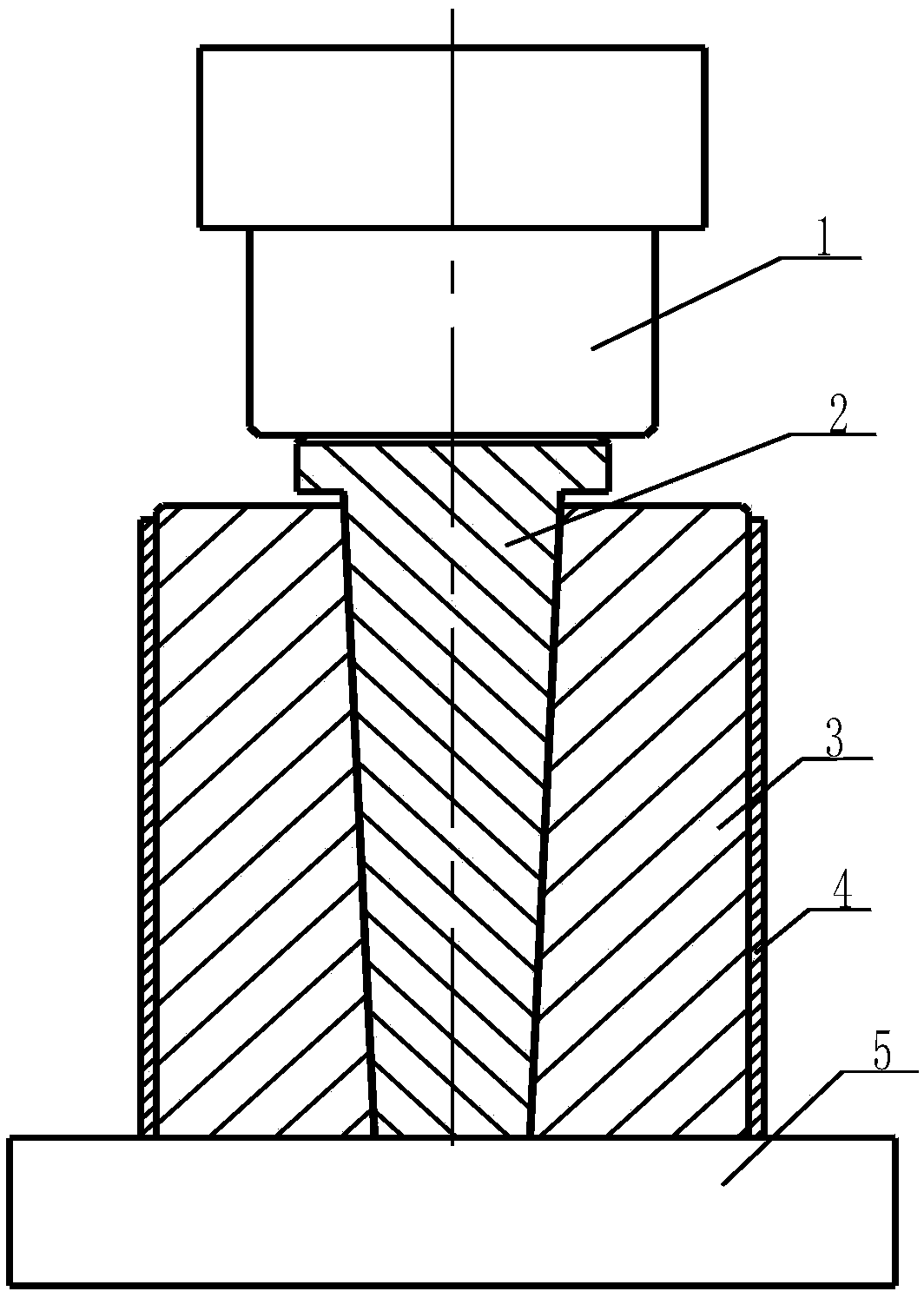

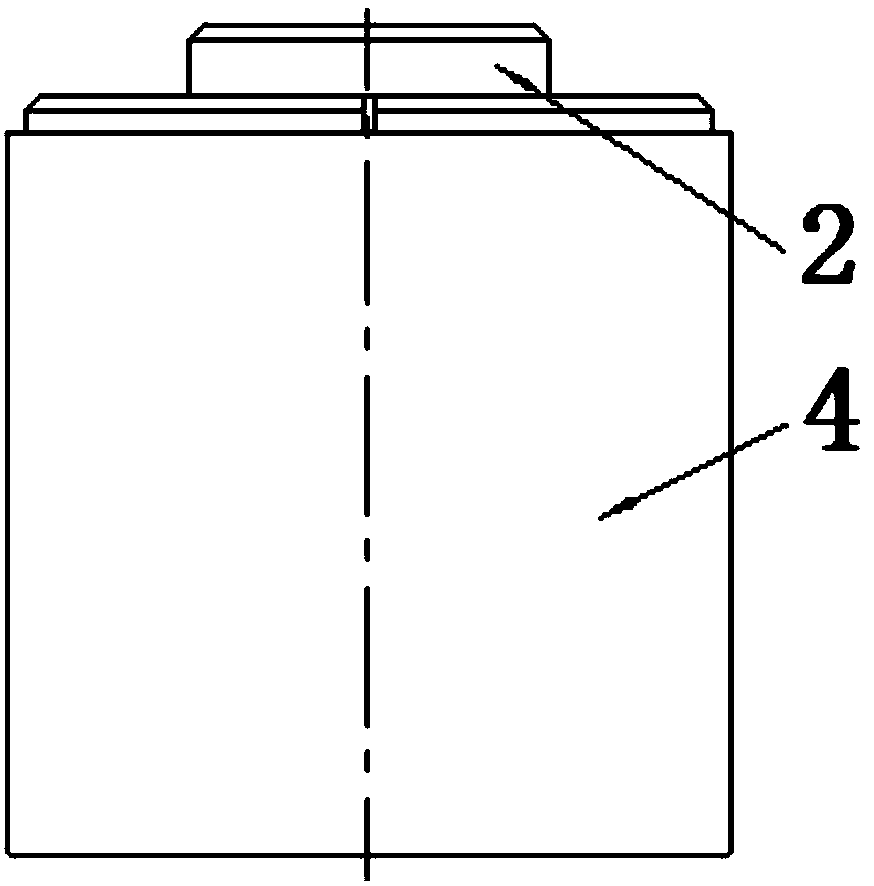

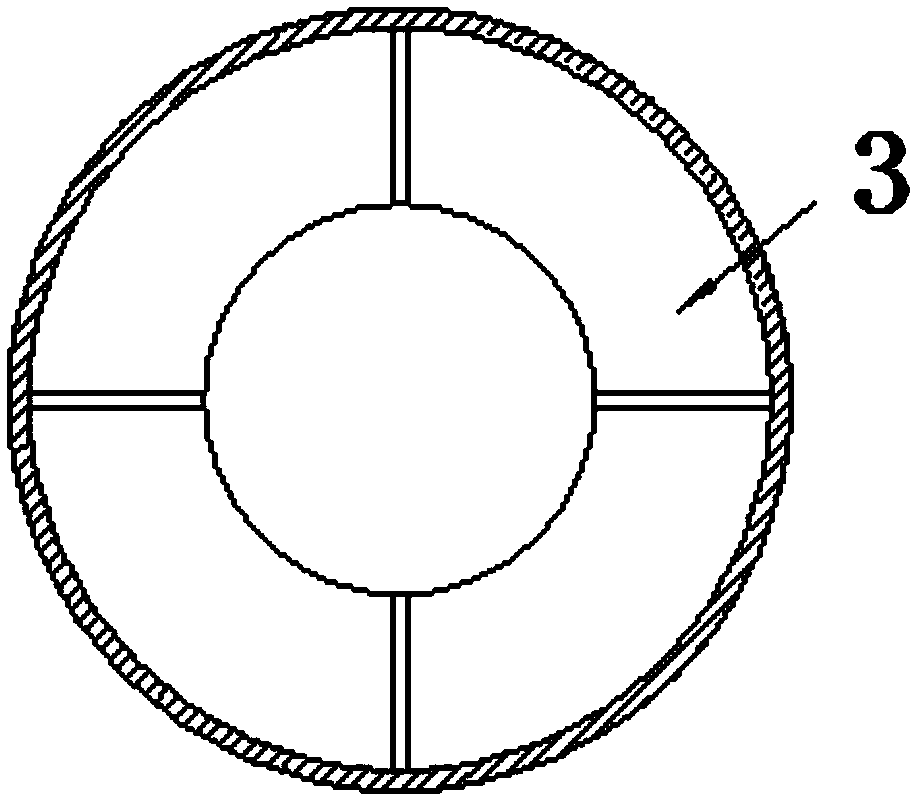

[0016] Such as figure 1 As shown in -3, the quick correction cylinder tool of the present invention includes a piston rod indenter 1, a tapered mandrel 2, a support block 3 and a bottom plate 5. The cone-shaped mandrel 2 is fixed on the piston rod head 1 of the hydraulic press, and the four support blocks 3 are evenly loaded into the cylinder 4 that needs to be rounded. The head 1 goes down, and the tapered mandrel 2 enters the inner tapered hole of the support block 3, so that the support block 3 moves radially from the inner diameter of the cylinder 4 to the outer diameter, so that the cylinder 4 is evenly stressed, and the cylinder 4 is completed. Correction. The support surface of the support block 3 is an arc surface adapted to the inner diameter of the cylinder body 4 . The tapered mandrel 2 is cylindrical with a chamfer at the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com