Auxiliary picking mechanical arm for pineapples

A mechanical arm and pineapple technology, applied in manipulators, agricultural machinery and implements, harvesters, etc., can solve the problems of easy tearing, damage to pineapple stems and buds, and large manual injuries, so as to save time and effort in operation and solve the problem of bending over. and the effect of easy injury and simplified mechanical operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

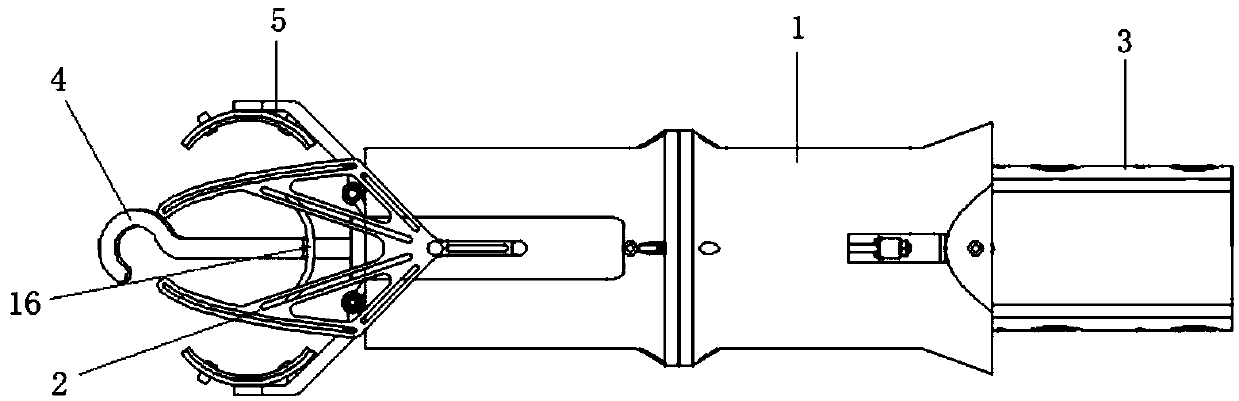

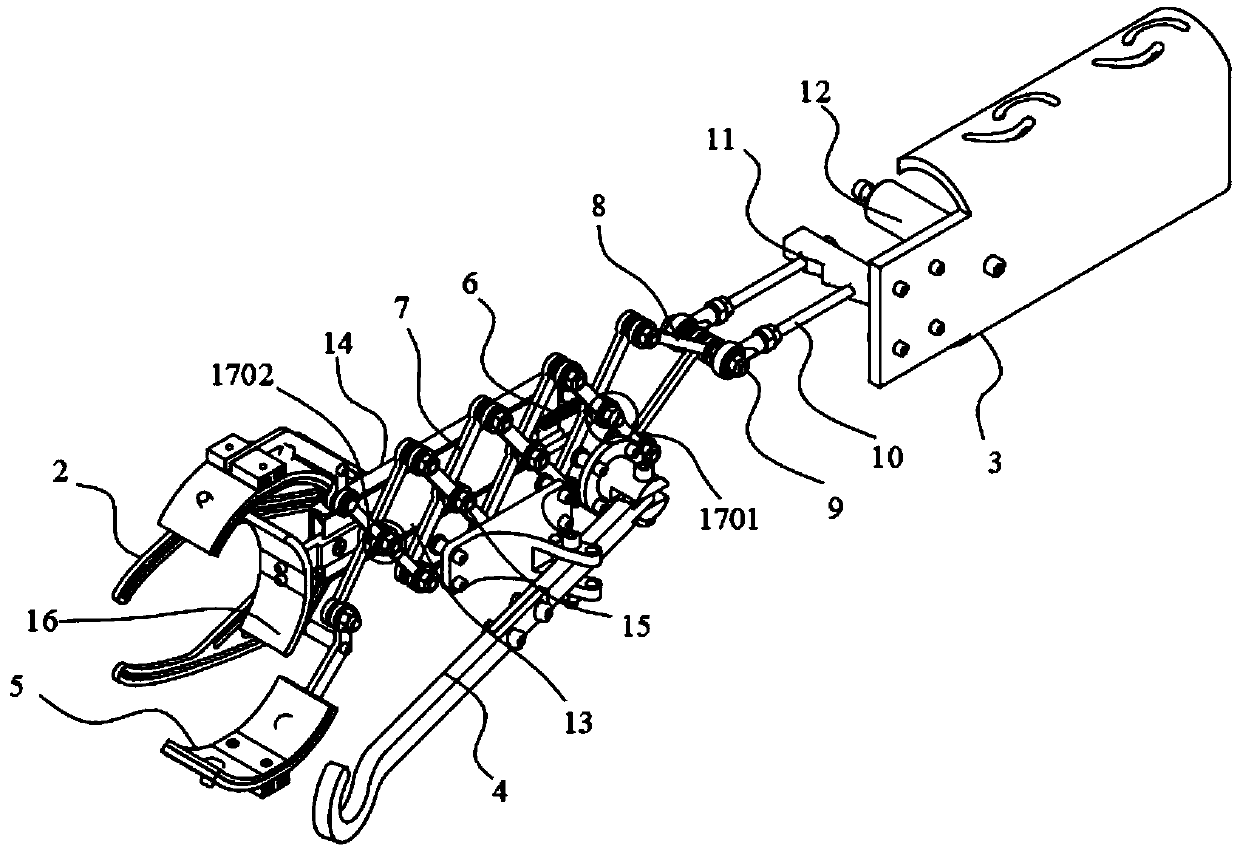

[0027] Such as figure 1 , a pineapple auxiliary picking mechanical arm, comprising a fixed shell 1, a guide groove plate 2, an arm support plate 3, a radial fixed hook 4, a grasping claw head 5, and a push plate 16, the fixed shell 1 and the arm support Board 3 links to each other, and this device can be worn on picker's arm place by described arm support board 3. The radial fixing hook 4 and the guide groove plate 2 are installed on both sides of the outer side of the fixing shell 1 respectively, and the two are oppositely arranged. In addition, the mechanical arm also includes a grasping structure and a power connection structure, which are all arranged inside the fixed shell 1 and the arm support plate 3, wherein the grasping structure includes the grasping structure and the power connection structure. Take the head 5 and the push plate 16.

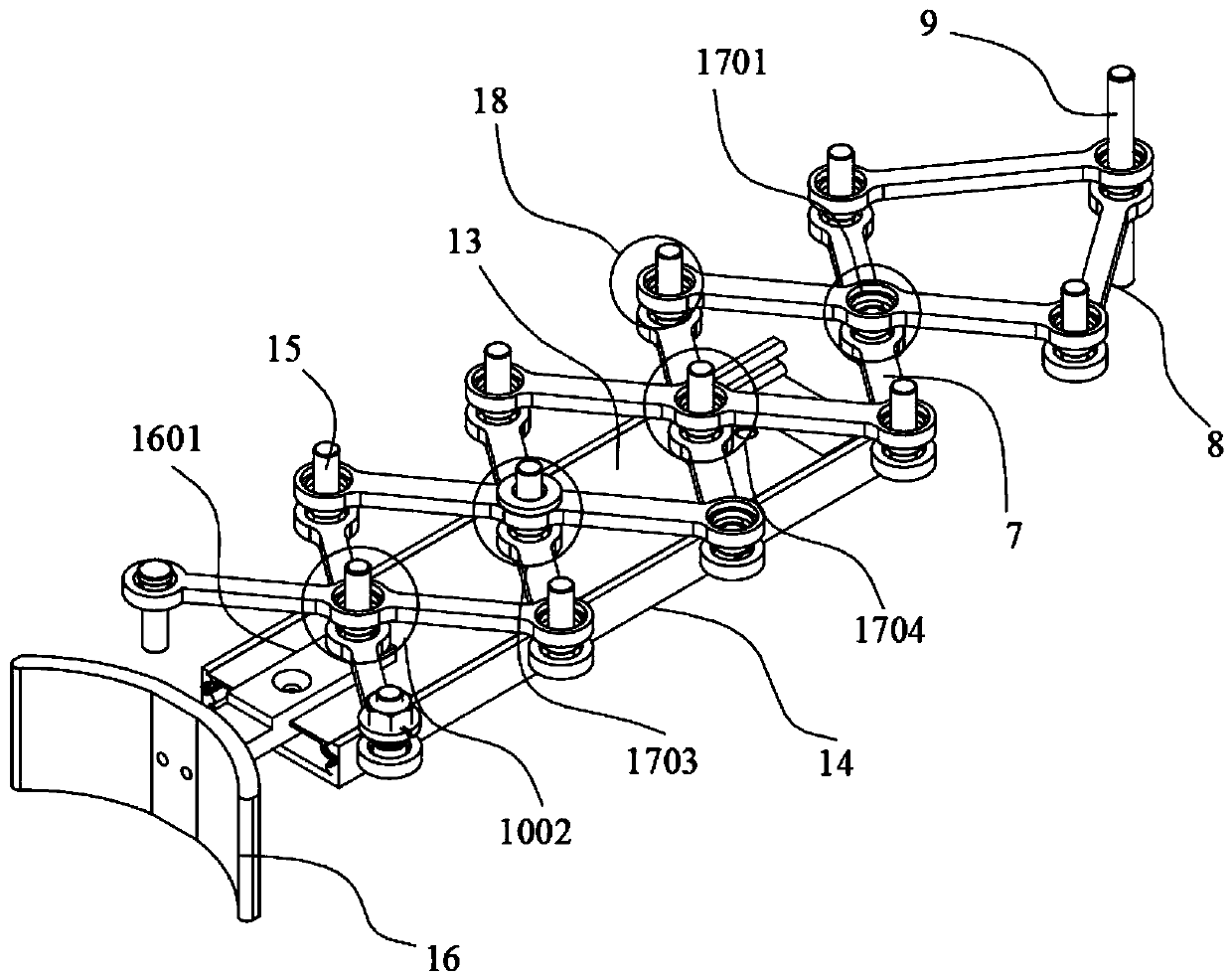

[0028] Such as figure 2 , 3 , the power connection mechanism includes a handle column 12, a handle 11, two power rods 10, two pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com