A kind of celery stalk cutting machine

A cutting machine and cutting knife technology, applied in metal processing and other directions, can solve the problems of low work efficiency, cutting tool cuts, troubles, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

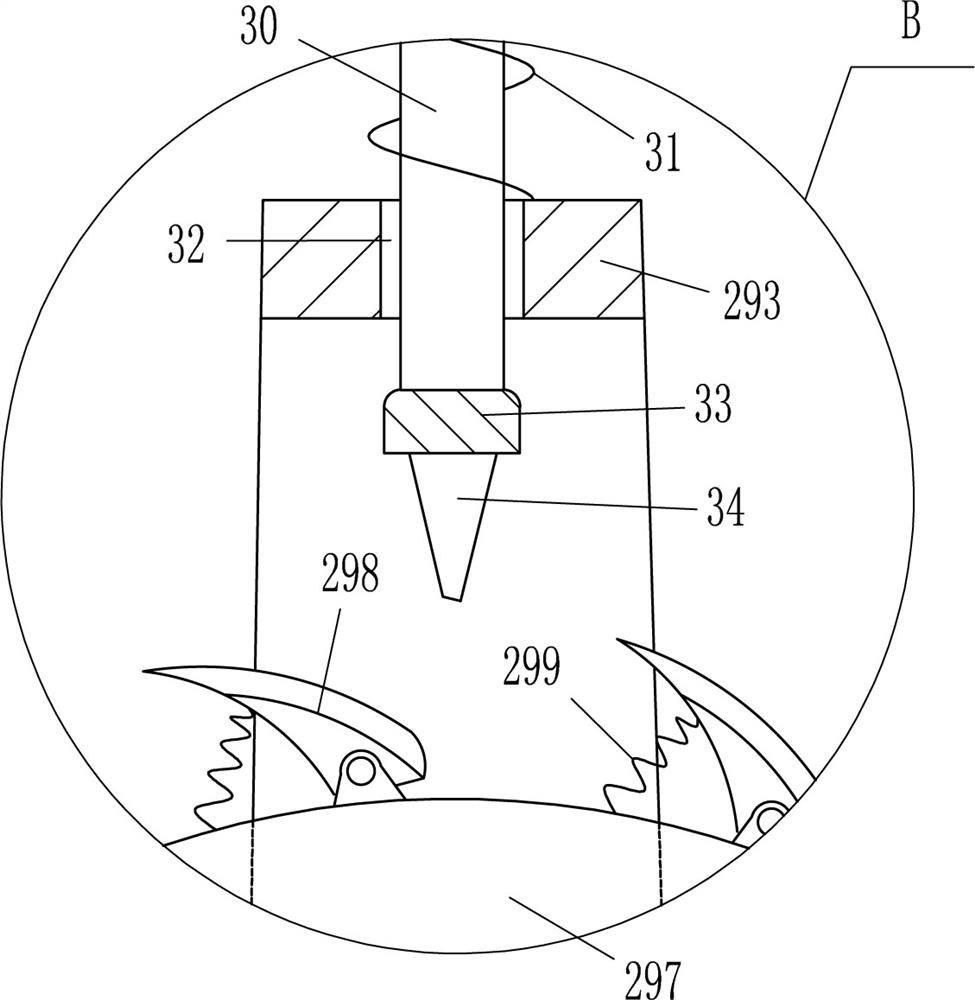

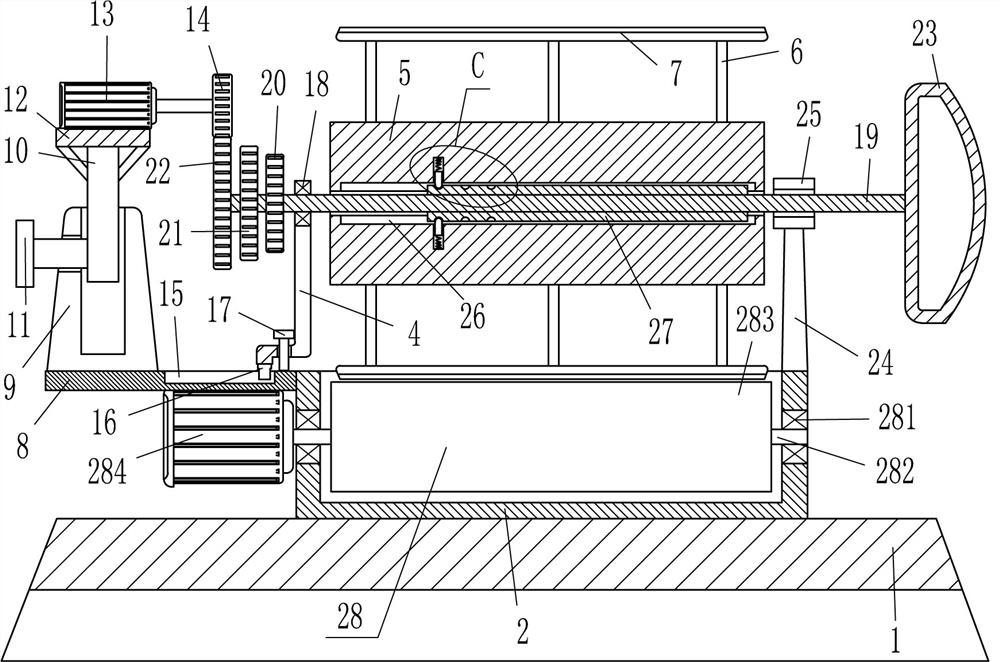

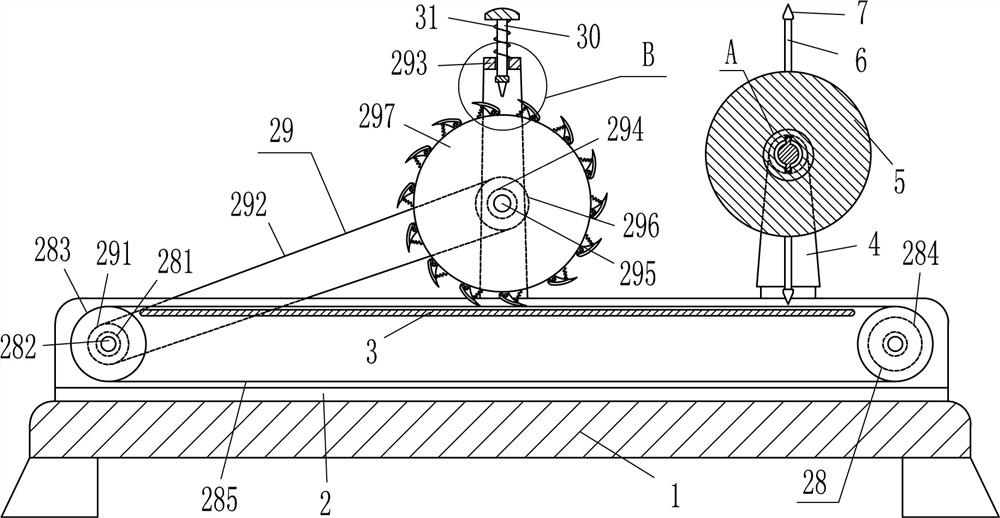

[0023] A celery stalk cutter such as Figure 1-5As shown, it includes a base 1, a u-shaped plate 2, a support plate 3, an L-shaped plate 4, a roller 5, a connecting rod 6, a cutter 7, a horizontal plate 8, a sleeve 9, a movable rod 10, and the first fastening bolt 11. Fixed plate 12, drive motor 13, first gear 14, horizontal slider 16, second fastening bolt 17, first bearing seat 18, first rotating shaft 19, pinion 20, middle gear 21, large gear 22, Handle 23, support plate 24, guide sleeve 25, guide block 27 and conveying device 28, base 1 top is equipped with u-shaped plate 2, is provided with conveying device 28 that can convey celery stem in u-shaped plate 2, support plate 3 Installed between the tops of the front and rear sides of the u-shaped plate 2, the support plate 3 cooperates with the conveying device 28, a support plate 24 is fixedly connected to the top right side of the front side of the u-shaped plate 2, and the guide sleeve 25 is installed on the top of the su...

Embodiment 2

[0025] A celery stalk cutter such as Figure 1-5 As shown, it includes a base 1, a u-shaped plate 2, a support plate 3, an L-shaped plate 4, a roller 5, a connecting rod 6, a cutter 7, a horizontal plate 8, a sleeve 9, a movable rod 10, and the first fastening bolt 11. Fixed plate 12, drive motor 13, first gear 14, horizontal slider 16, second fastening bolt 17, first bearing seat 18, first rotating shaft 19, pinion 20, middle gear 21, large gear 22, Handle 23, support plate 24, guide sleeve 25, guide block 27 and conveying device 28, base 1 top is equipped with u-shaped plate 2, is provided with conveying device 28 that can convey celery stem in u-shaped plate 2, support plate 3 Installed between the tops of the front and rear sides of the u-shaped plate 2, the support plate 3 cooperates with the conveying device 28, a support plate 24 is fixedly connected to the top right side of the front side of the u-shaped plate 2, and the guide sleeve 25 is installed on the top of the s...

Embodiment 3

[0028] A celery stalk cutter such as Figure 1-5 As shown, it includes a base 1, a u-shaped plate 2, a support plate 3, an L-shaped plate 4, a roller 5, a connecting rod 6, a cutter 7, a horizontal plate 8, a sleeve 9, a movable rod 10, and the first fastening bolt 11. Fixed plate 12, drive motor 13, first gear 14, horizontal slider 16, second fastening bolt 17, first bearing seat 18, first rotating shaft 19, pinion 20, middle gear 21, large gear 22, Handle 23, support plate 24, guide sleeve 25, guide block 27 and conveying device 28, base 1 top is equipped with u-shaped plate 2, is provided with conveying device 28 that can convey celery stem in u-shaped plate 2, support plate 3 Installed between the tops of the front and rear sides of the u-shaped plate 2, the support plate 3 cooperates with the conveying device 28, a support plate 24 is fixedly connected to the top right side of the front side of the u-shaped plate 2, and the guide sleeve 25 is installed on the top of the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap