A special drilling tool for car washing jug with pressing function

A technology for drilling tooling and washing pots, which is applied in the direction of boring/drilling, drilling/drilling equipment, manufacturing tools, etc., which can solve the problems of complex tooling and fixtures, low efficiency, and greater impact on the processing efficiency of washing pots. Achieve uniform drilling quality, high drilling efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The embodiments described below are by way of example only, and other obvious modifications will occur to those skilled in the art.

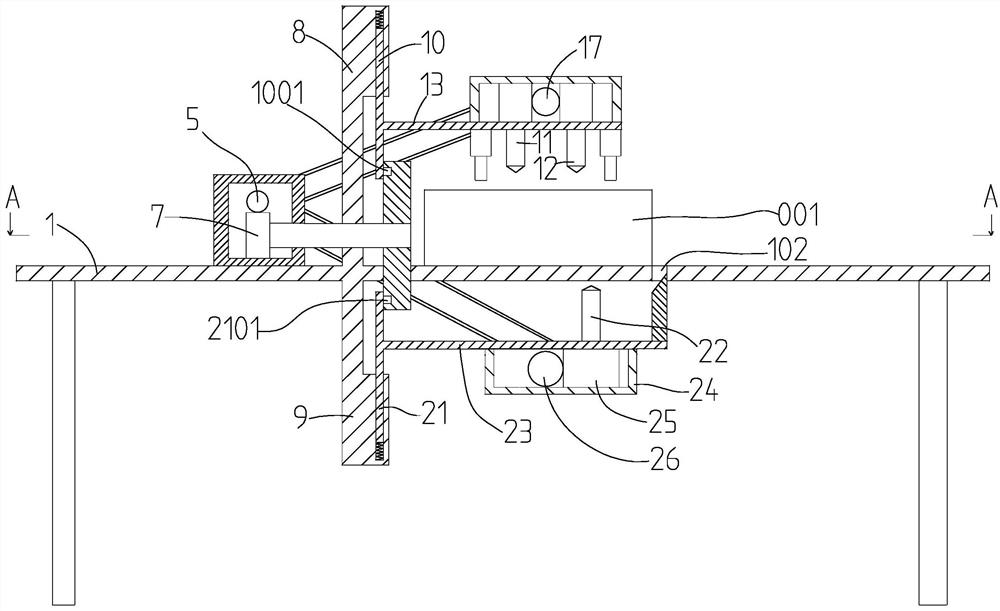

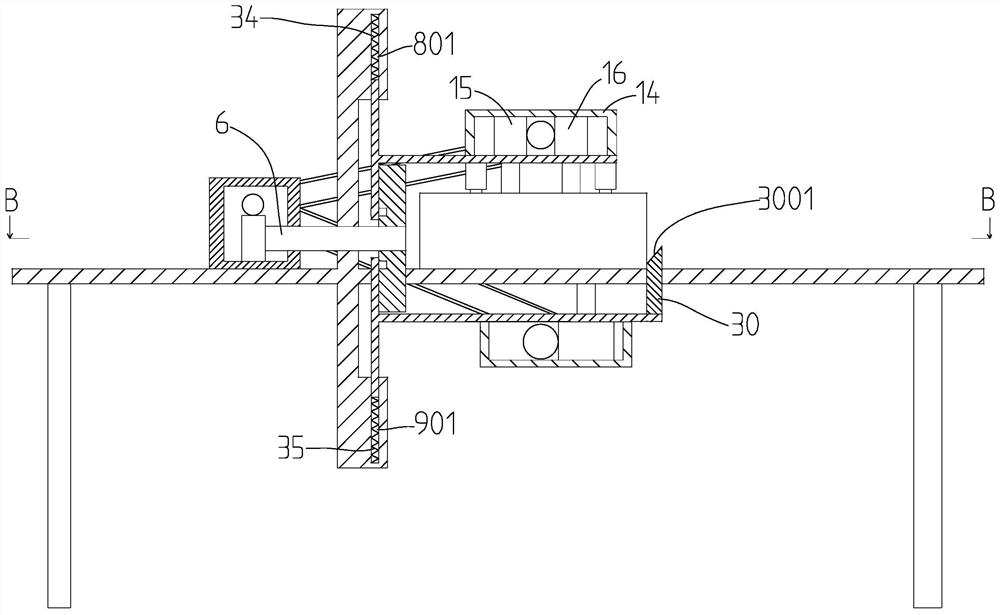

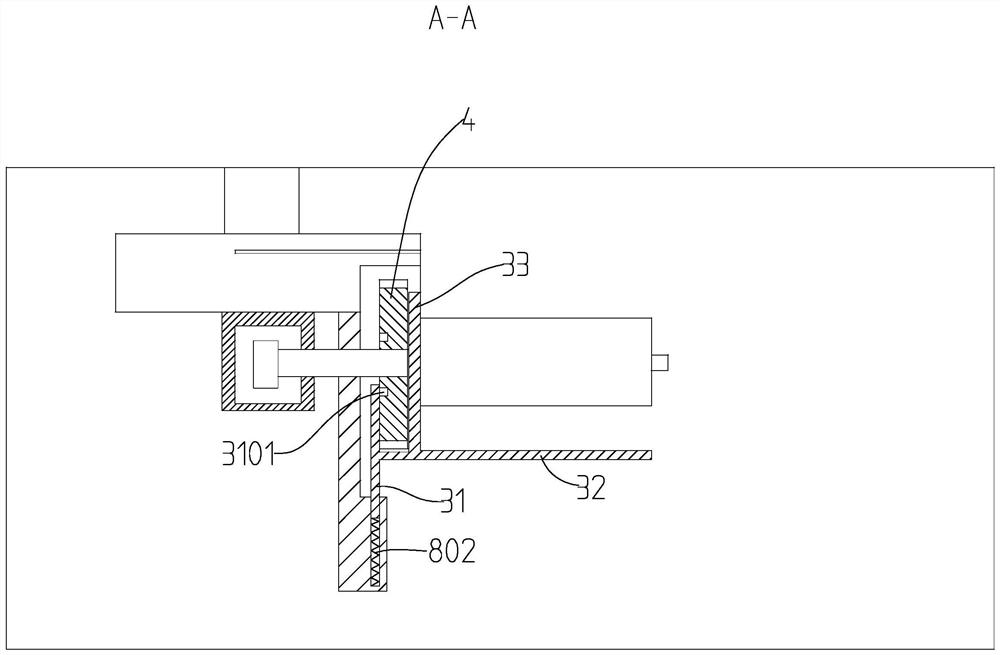

[0026] like Figure 1-8 As shown, a special drilling tool for a car washing pot with a pressing function includes a frame 1, a drive motor 2, a reducer 3, and a runner 4. The drive motor 2 is installed on the frame 1, and the deceleration The device 3 includes a casing mounted on the frame 1 and located at the output shaft end of the drive motor 2. The casing is rotatably connected with a first worm 5 that is coaxially and fixedly connected to the output shaft of the drive motor 2. A first rotating shaft 6 is rotatably connected to the direction perpendicular to the first worm 5, and a first worm wheel 7 engaged with the first worm 5 is installed on the first rotating shaft 6 at one end located in the casing; the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com