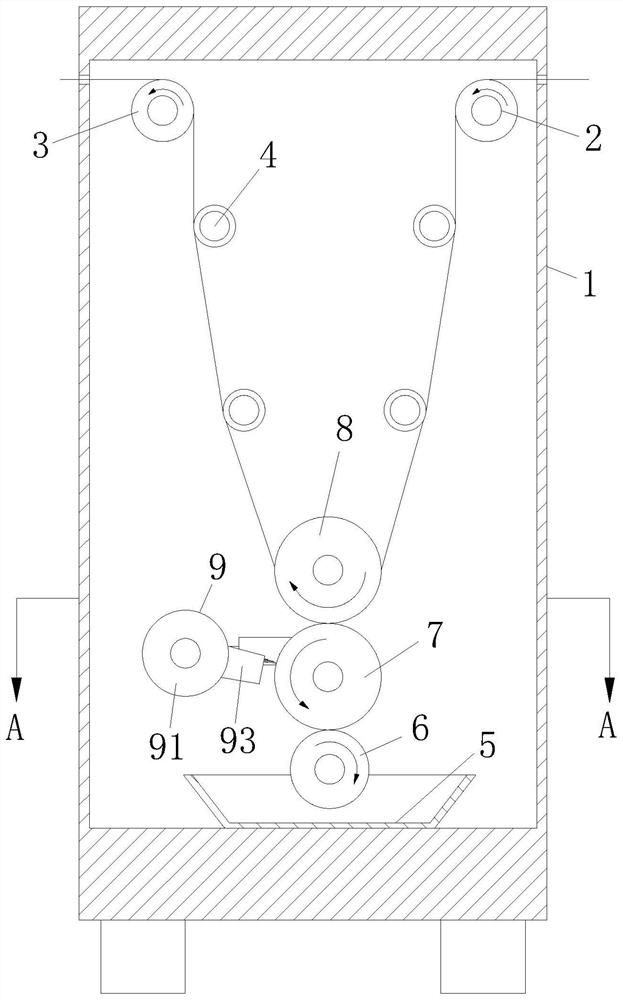

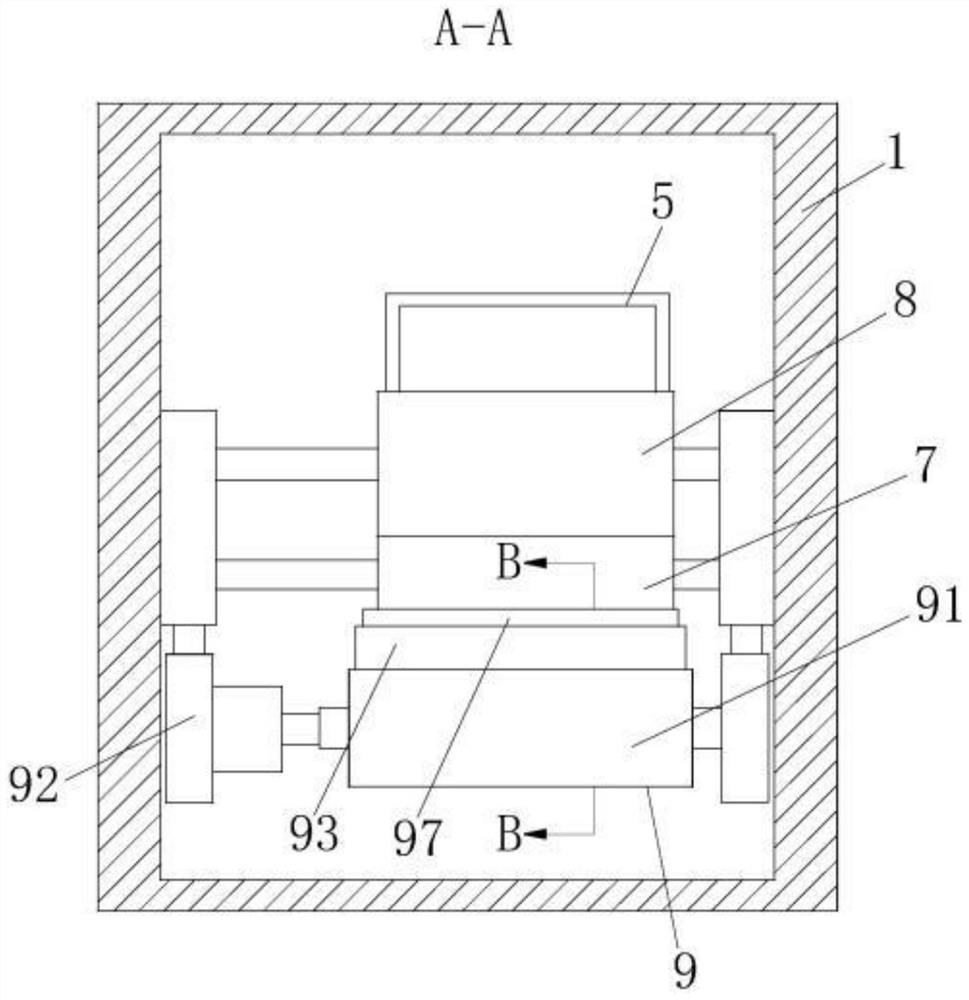

A gravure printing machine

A technology of gravure printing machines and printing machines, which is applied in the direction of gravure rotary printing machines, printing machines, rotary printing machines, etc., which can solve problems such as damage and fracture, metal fatigue of scraping blades, and influence on scraping effect, so as to save costs and avoid Effects of blocked return pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

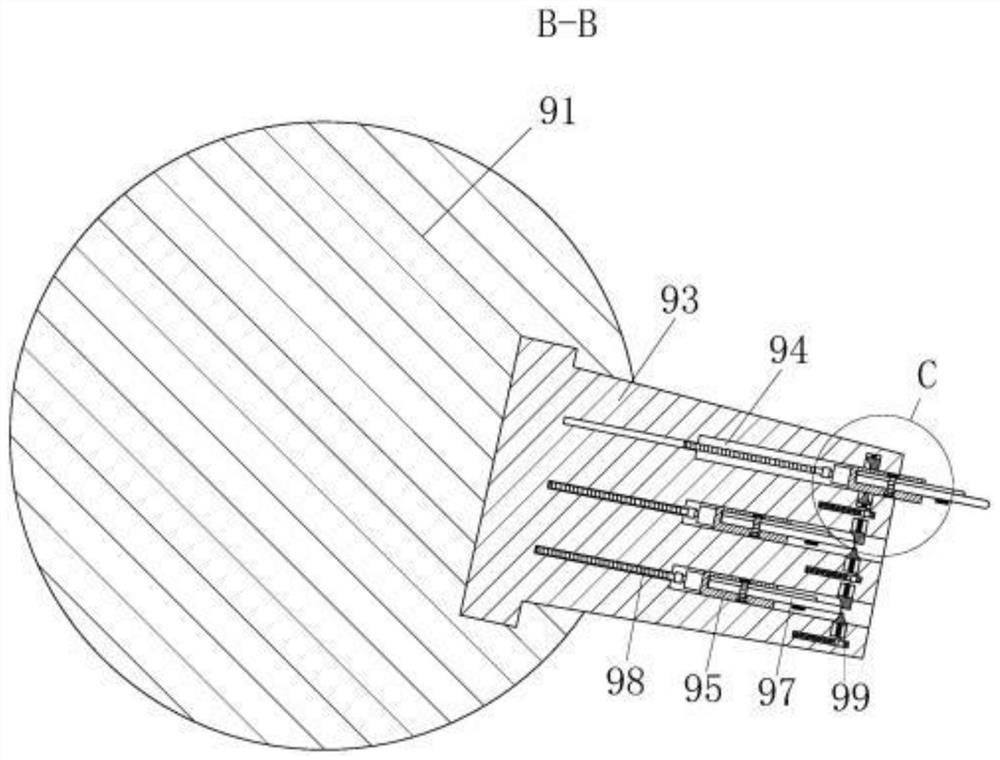

[0025] As an embodiment of the present invention, the grinding unit 99 includes a No. 1 whetstone 991, a No. 2 whetstone 992 and a No. 1 spring; the No. 1 whetstone 991 is slidably arranged in the No. 1 groove opened on the top wall of the installation groove 94 Inside, the No. 1 oil stone 991 is connected in the No. 1 groove through the No. 1 spring; the No. 2 oil stone 992 is slidably connected in the No. 2 groove opened on the bottom wall of the installation groove 94, and the No. 2 oil stone 992 is connected through the No. 2 spring. In the No. 2 groove, the left sides of the No. 2 oil stone 992 and the No. 1 oil stone 991 are arc-shaped, so that the ink scraper 97 can stretch out. When the No. 2 servo motor drives the ink scraper 97 to retract in the installation groove 94, the No. 1 oil stone 991 is pressed on the upper side of the ink scraper 97 under the promotion of the No. 1 spring, and the upper side of the ink scraper 97 is polished. No. 9 oil stone 992 is pressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com