Rotation page folding device with variable cutting specification and folding method

A cutting and specification technology, applied in the direction of rotary printing machine, printing, printing machine, etc., to achieve the effect of speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

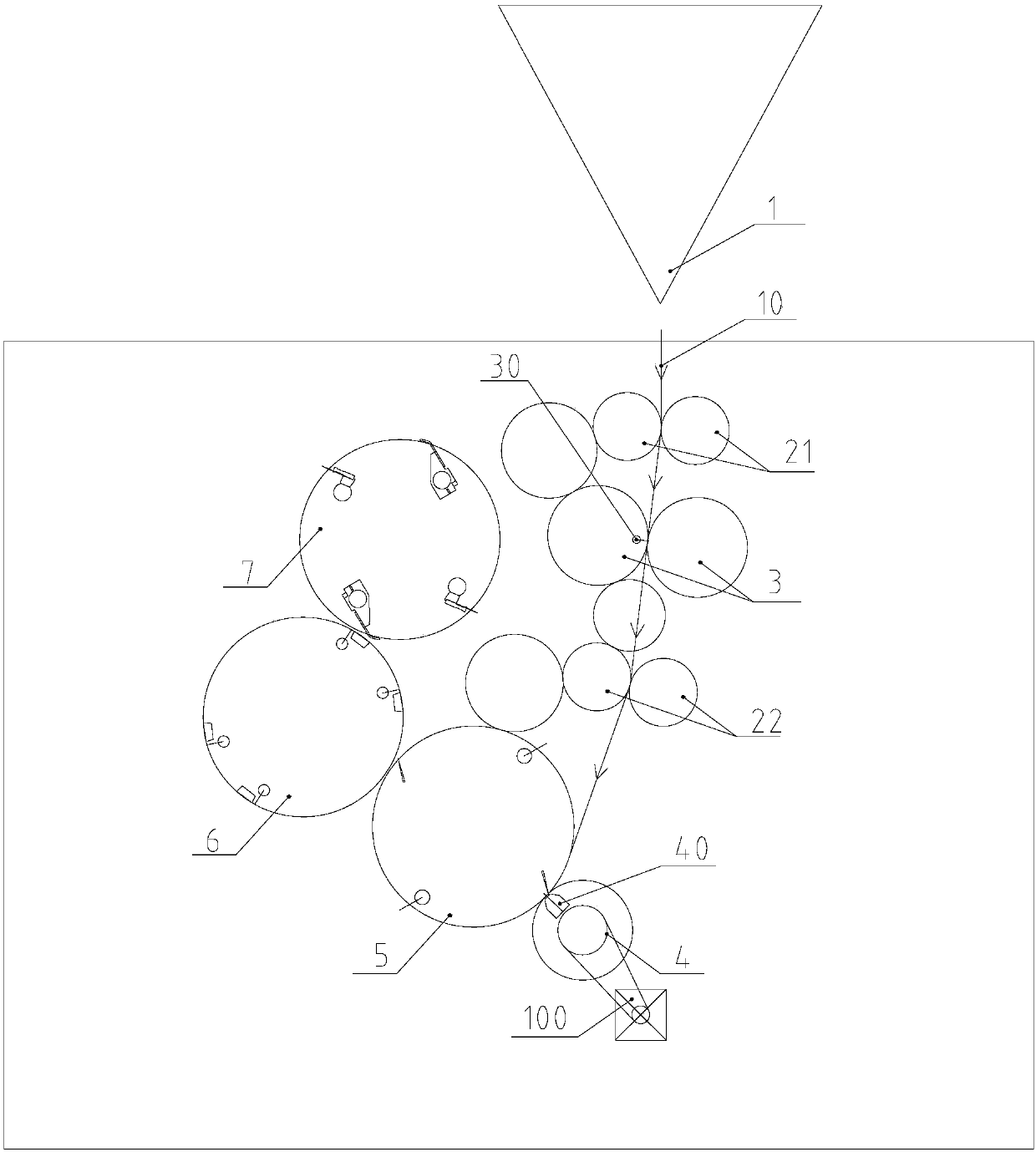

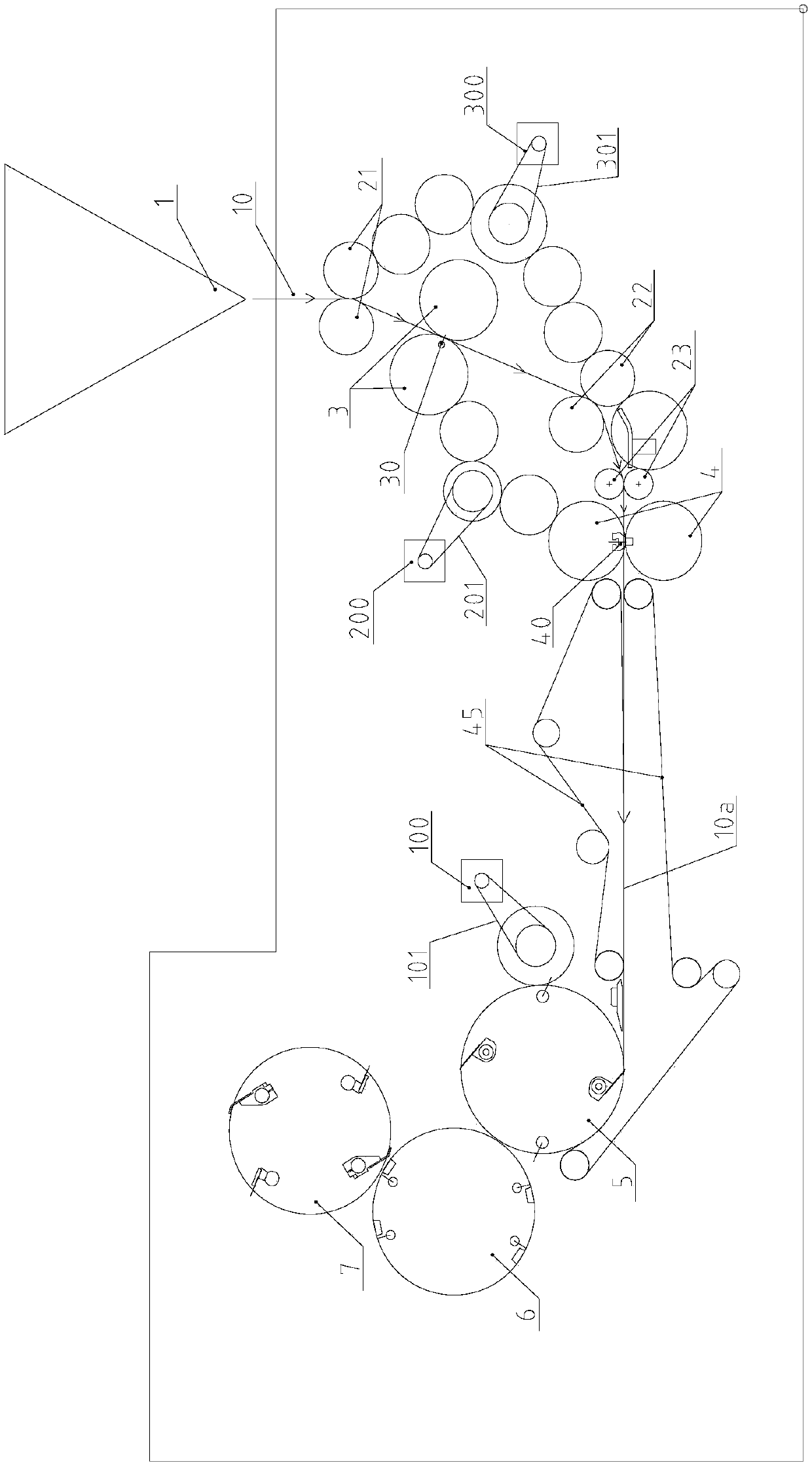

[0024] The present invention will be further described below in conjunction with accompanying drawing.

[0025] see figure 2 , the rotary folding device with variable cutting specifications of the present invention, the triangular plate 1, a pair of first pulling rollers 21, a pair of punching cylinders 3, and a pair of second pulling rollers arranged in sequence according to the path of the paper tape 10 22. A pair of third pulling rollers 23, a pair of cutting cylinders 4, a conveyor belt 45, a pin cylinder 5 and a folding cylinder 6, wherein,

[0026] The first pulling roller 21, the second pulling roller 22 and the third pulling roller 23 are all driven by a pulling roller motor 200; the pulling roller motor 200 passes through the third synchronous belt transmission mechanism 201 and two sets of third gears in turn. The transmission mechanism transmits the driving force to the first paper pulling roller 21 and the second paper pulling roller 22 respectively, and the seco...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap