Anticollision energy absorption assembly for protecting tank body of hazardous chemicals transport vehicle

A technology for hazardous chemicals and trucks, which is applied to goods transport vehicles, vehicles for freight transport, transport objects, etc., can solve problems such as hidden dangers, explosions, and unsatisfactory buffer energy absorption effects, and achieve good buffer protection. Vehicle safety, ensuring the effect of energy absorption and buffering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

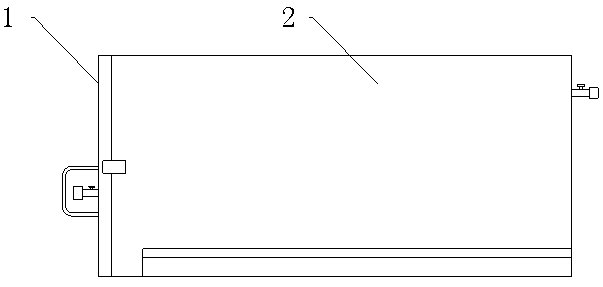

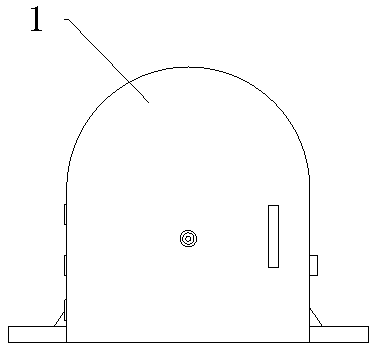

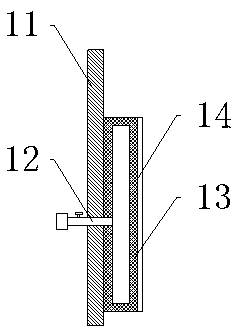

[0025] see Figure 1-Figure 7 , the present invention provides a technical solution: an anti-collision energy-absorbing assembly for protecting the tank body of a hazardous chemical transport vehicle, including a sealing mechanism 1 and an anti-collision mechanism 2, the sealing mechanism 1 is installed at the left end of the anti-collision mechanism 2, and the sealing Mechanism 1 includes a sealed door 11, an inflatable tube 12, a sealed air bag 13 and a sealed film 14, and the anti-collision mechanism 2 includes a shell 21, a rubber pad 22, a protective air bag 23, a honeycomb explosion-proof block 24, a telescopic rod 25, a spring 26 and an inner tank Body 27.

[0026] As an embodiment of the present invention: in the sealing mechanism 1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com