Clamping apparatus for lifting H-shaped steel beam and lifting method thereof

A technology of H-beam and steel beam, which is applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of poor mobility, time-consuming and laborious hoisting of H-beam steel beam, etc., and achieves convenient operation, improved hook adhesion, and convenient production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

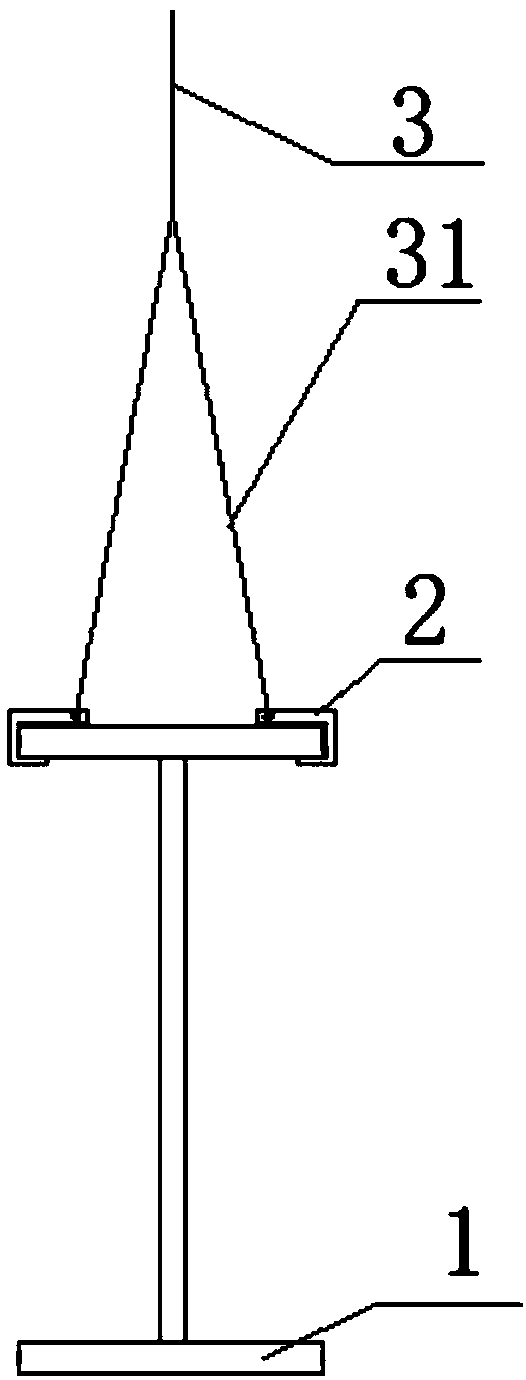

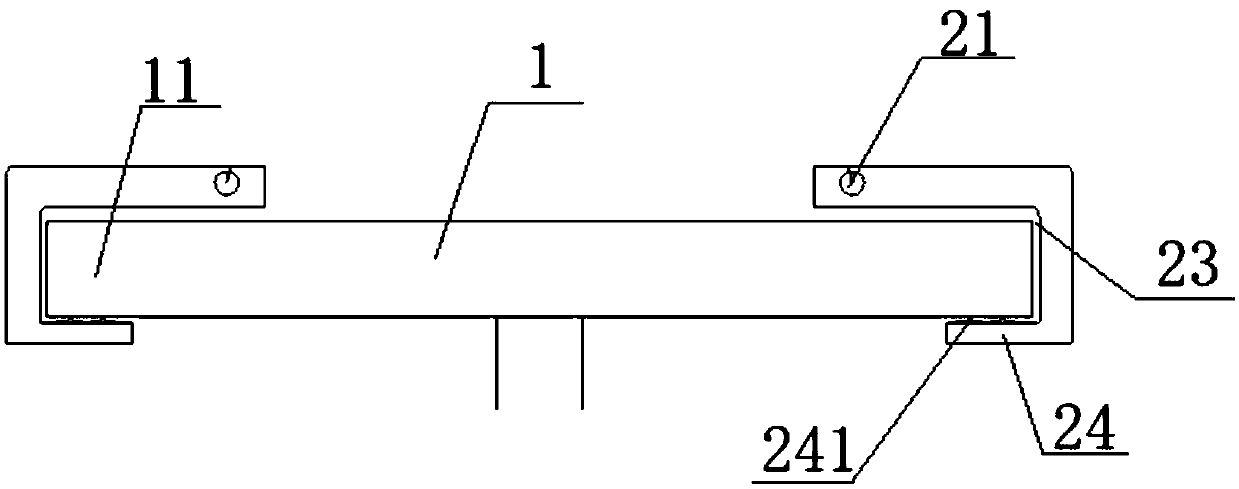

[0046] A kind of jig for hoisting and transporting H-shaped steel beams of the present embodiment, such as figure 1 , 2 As shown, it includes a steel wire rope 3 and lifting clamps 2 symmetrically distributed on the H-shaped steel beam 1; the lifting clamp 2 is in the shape of a rectangular opening hook, including a lifting hole 21 and a card slot 23 connected as one with the hook end. 24; the clamping groove 23 fits the shape and thickness of the far end 11 of the steel beam flange plate on both sides of the H-shaped steel beam 1, is clipped to the far end 11 of the steel beam flange plate, and passes through the hoisting hole 21 and the steel wire rope branch 31 of the steel wire rope 3 The hooking end 24 cooperates with the card slot 23 and fastens to the bottom of the far end 11 of the flange plate of the steel beam.

[0047]A jig for hoisting H-shaped steel girders in this embodiment is applied to hoisting H-shaped steel girders 1. After the H-shaped steel girders 1 are ...

Embodiment 2

[0049] A fixture for hoisting H-shaped steel girders in this embodiment has the same basic structure as in Embodiment 1, and the improvement is that evenly distributed hook grooves 241 are arranged on the upper surface of the hook end 24 to improve the height of the lifting clamp. Tool 2 is hook-holding adhesion to the H-shaped steel girder 1. There are even pairs of hoisting fixtures 2, which can be buckled symmetrically, and can be applied in an adaptive quantity according to the specifications of the H-shaped steel beam 1. For example, if the length is 6m, at least 3 pairs of hoisting fixtures 2 need to be laid out, symmetrically and evenly buckled. The far end 11 of the steel beam flange plate on both sides of the H-shaped steel beam 1; the steel material of Q345C is selected for use by the hoisting clamp 2, which is easy to obtain materials, convenient to manufacture, and can also reuse waste.

[0050] A fixture for hoisting H-shaped steel girders of this embodiment can b...

Embodiment 3

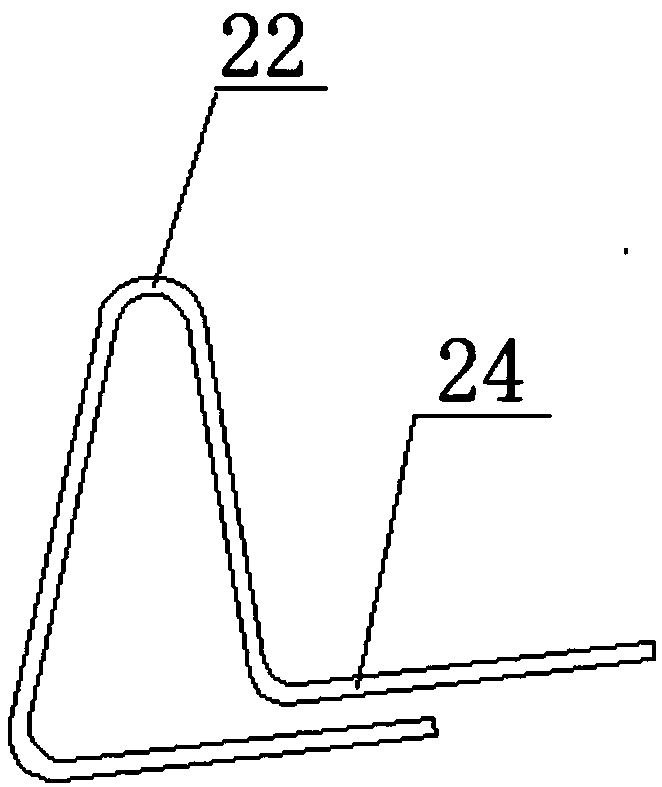

[0057] A kind of double-hook fixture for hoisting and transporting H-shaped steel beams of the present embodiment, such as image 3 , 4 As shown, it includes a steel wire rope 3 and a hoisting fixture 2 hung on both ends of the H-shaped steel beam 1; the hoisting fixture 2 is a double V-shaped hook, and the bottom is two hooking ends 24, and the double V-shaped hook passes through The hoisting connection part 22 is connected as a whole, and the steel wire rope sub-strands 31 of the steel wire rope 3 are connected to the hoisting connection part 22 .

[0058] A double-hook fixture for hoisting H-shaped steel girders in this embodiment is applied to the lifting of H-shaped steel girders 1. For relatively short lengths, such as less than 1 m, and heights of less than 500 mm, such as H400 or 300 or 150 mm, etc., The H-shaped steel girder 1 with a relatively large width is convenient for hooking from both ends. Combined with the structural characteristics of the symmetrical steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com