Staircase assembly and mounting method

A staircase and assembly technology, applied in the direction of stairs, treads and riser units, can solve the problems of reducing construction efficiency, prolonging construction period, and small contact area, so as to save manpower and material resources, improve structural stability, and increase contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The directional terms such as up, down, left, right, front, back, front, back, top, and bottom that are mentioned or may be mentioned in this specification are defined relative to the structures shown in the drawings. The words " "Inside" and "outside" respectively refer to the direction toward or away from the geometric center of a specific component. They are relative concepts, so they may change accordingly according to their different positions and different usage states. Accordingly, these or other directional terms should not be construed as limiting terms.

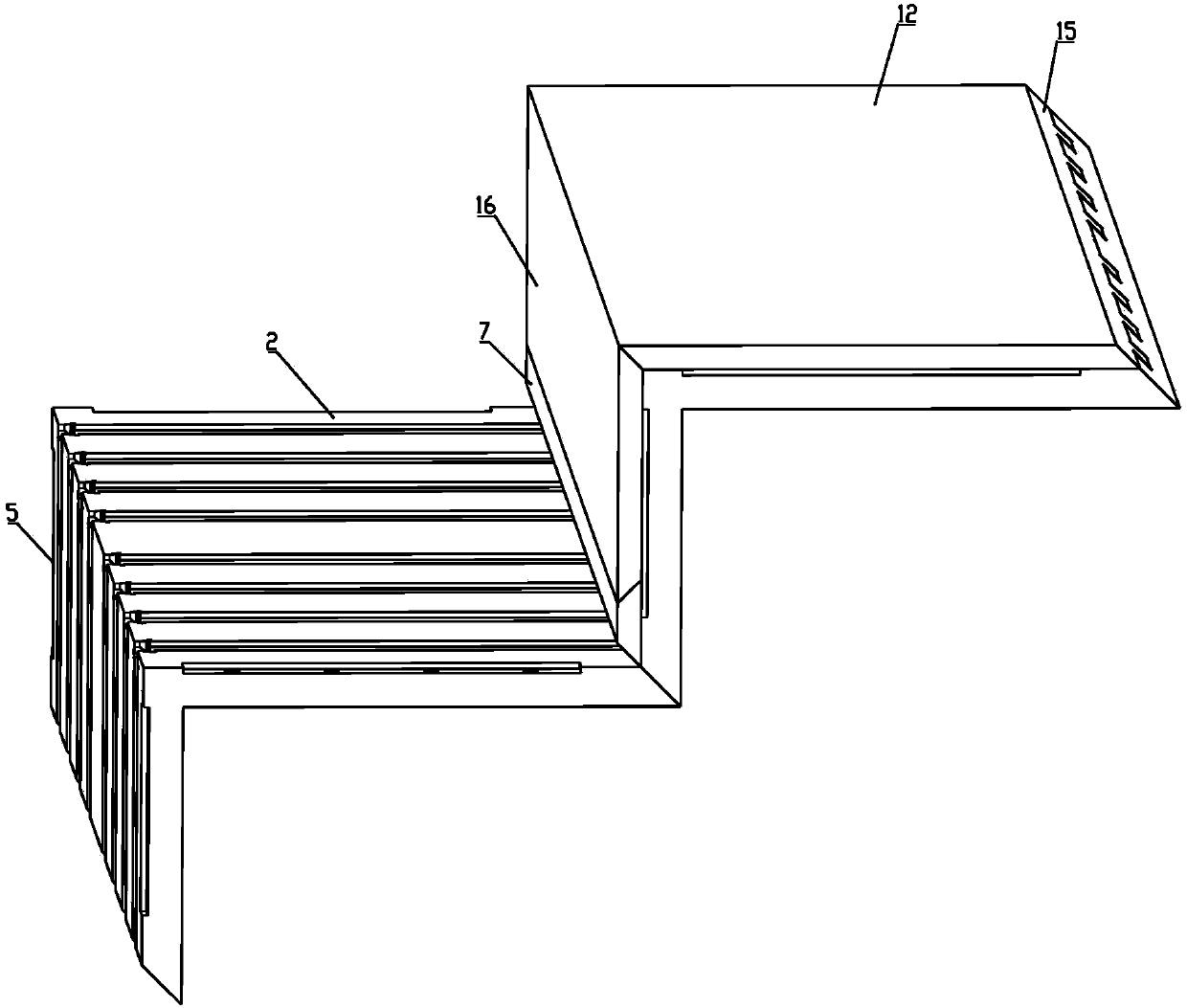

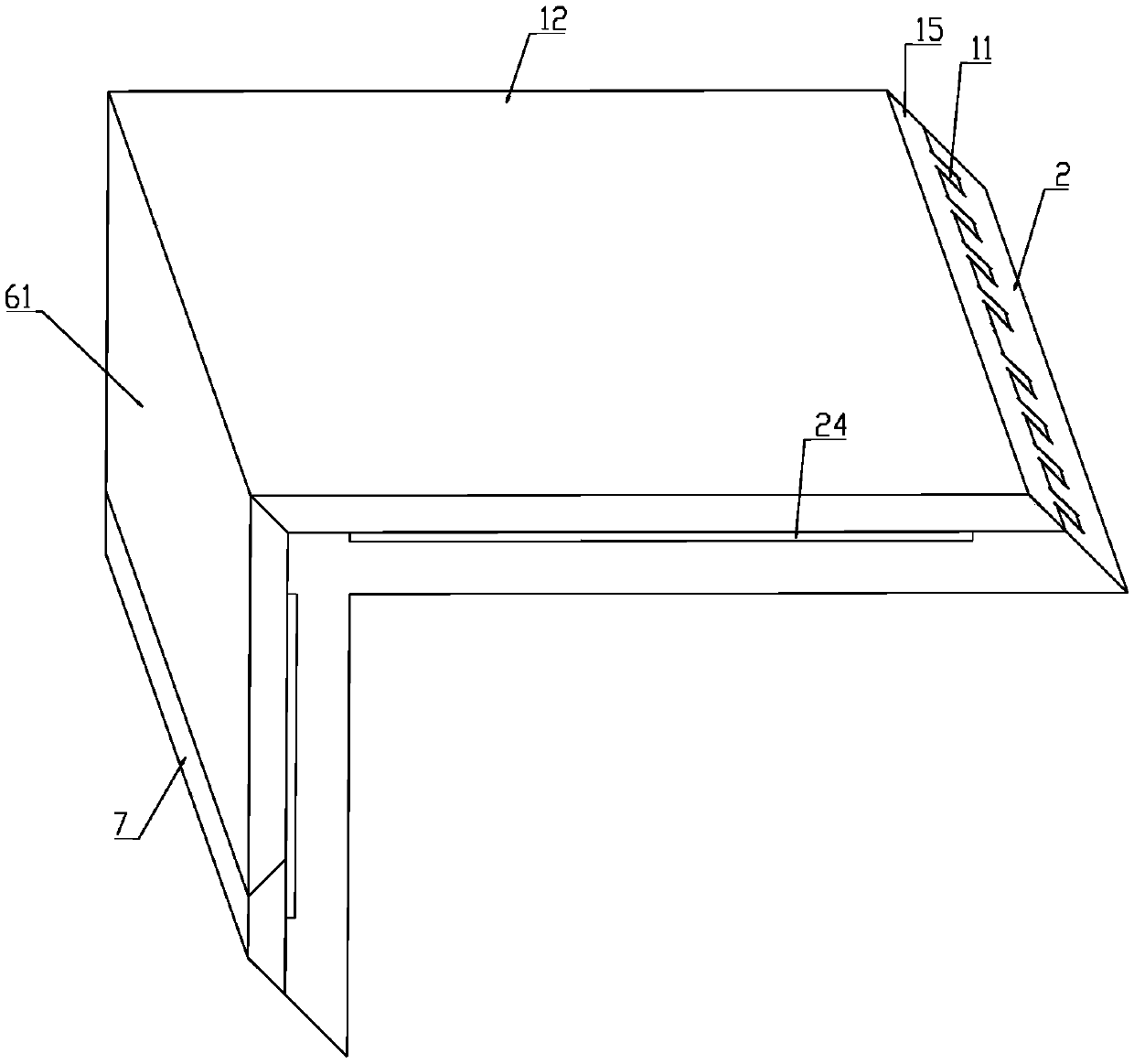

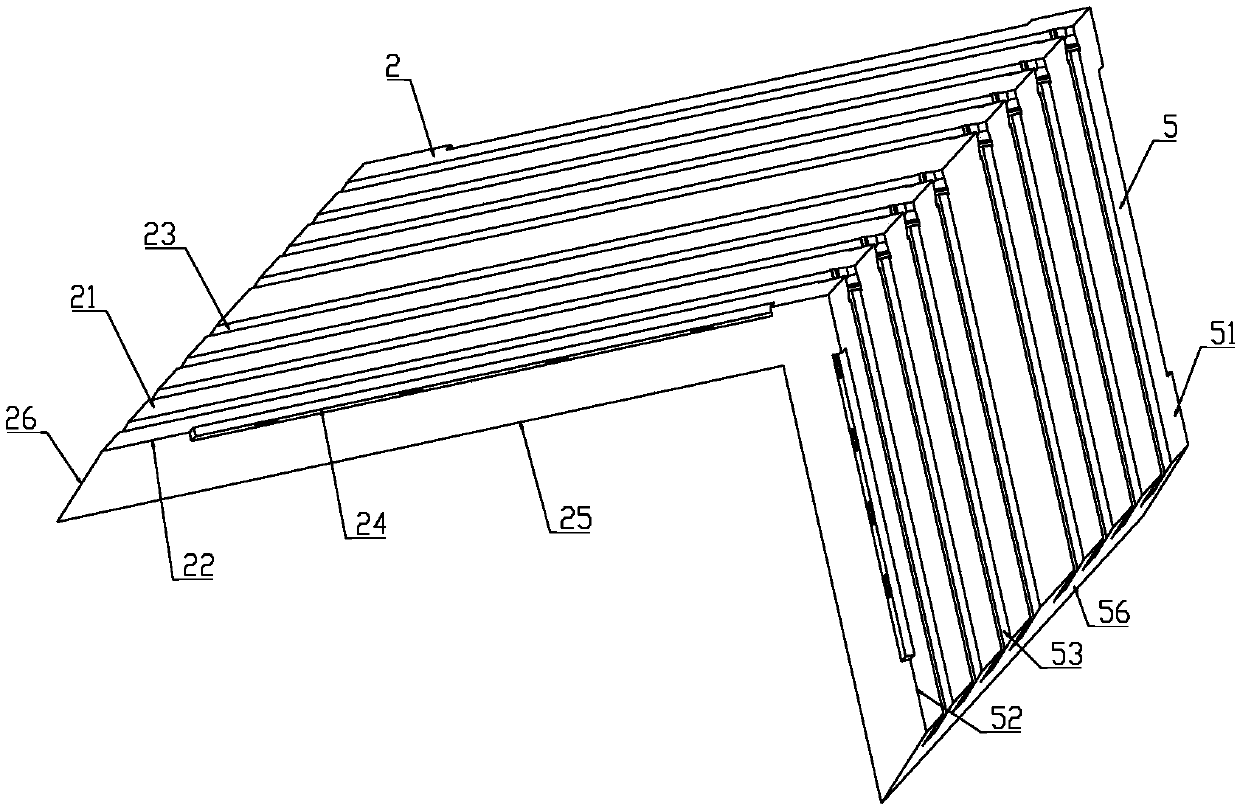

[0027] figure 1 A structural schematic diagram of the stair assembly provided for an optional embodiment of the present invention, figure 2 A schematic structural view of the stair assembly provided in an optional embodiment of the present invention, image 3 A schematic structural diagram of vertically connected first substrates and second substrates provided for an alternative embodiment of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com