Sliding frame for construction of fabricated steel structure buildings

A technology of building construction and steel structure, applied in the direction of building, building structure, housing structure support, etc., can solve the problem that construction personnel can only walk on its support platform, achieve reasonable structure design, avoid time waste, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

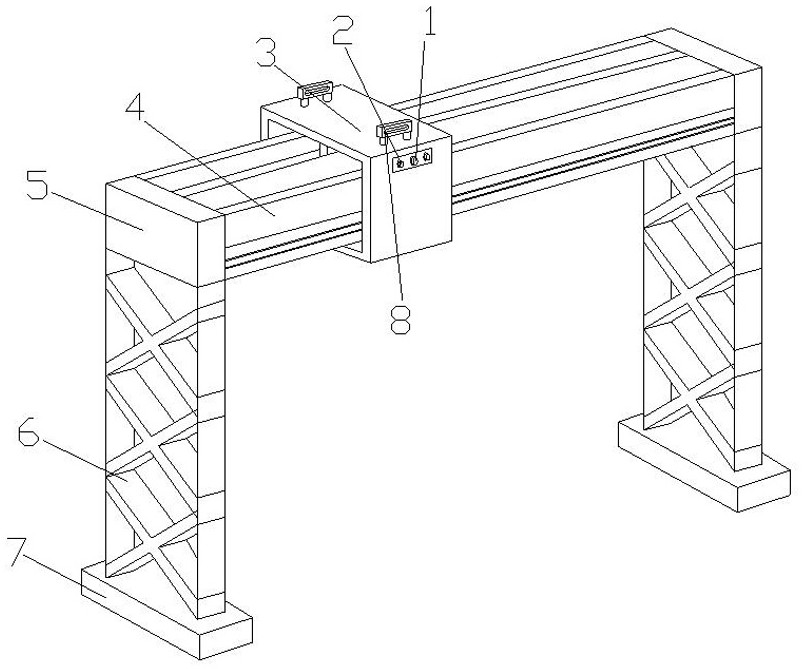

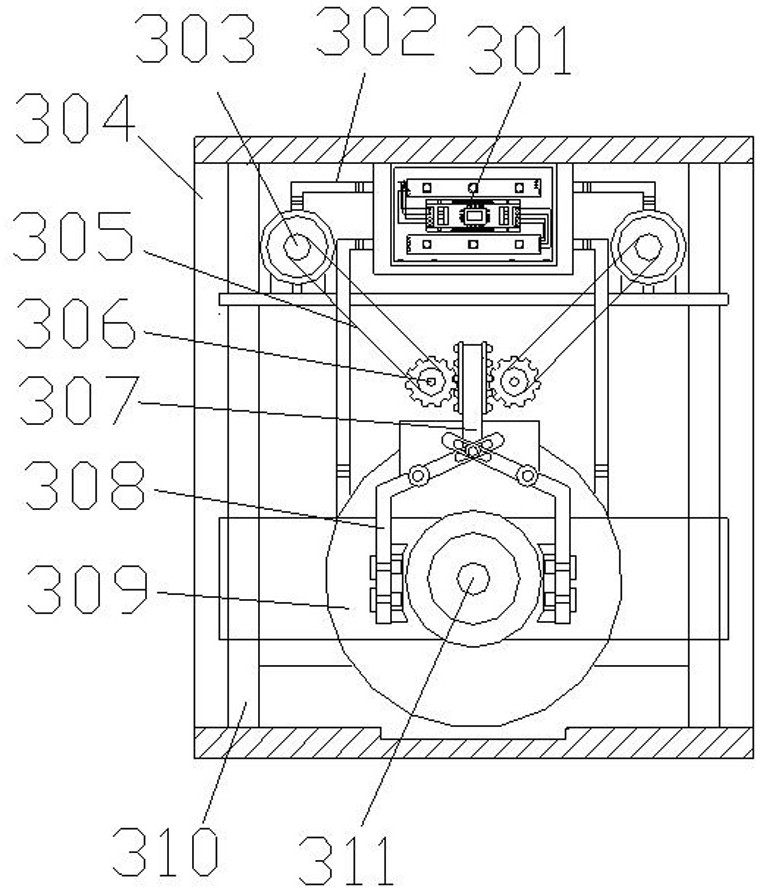

[0010] The sliding frame used for the construction of a prefabricated steel structure building includes two columns 6 and a sliding track 4 horizontally supported on the top of the two columns 6; the sliding track 4 is provided with a sliding device 3, and the sliding device 3 includes a shell 304, the casing 304 is supported with a roller 311 located on the sliding track 4, the roller 311 is driven by a mobile motor 309 fixed in the casing 304, the roller 311 is also equipped with a brake mechanism, and the brake mechanism includes two folding rods 308, One end of the two folding rods 308 is hinged, and the other end is fixed with a brake pad, and the middle part of the flange where the hinged ends of the two folding rods 308 are located is hinged in the casing 304 or on the inner support of the casing 304, so that the two folding rods 308 have brake pads. One end is placed on both sides of the roller 311. The brake mechanism also includes a double-sided rack 307. One end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com