Elevator shaft anti-falling net structure and construction process thereof

A technology of anti-falling nets and elevator shafts, which is applied in the direction of building construction, construction, and building materials processing, can solve problems such as high risk, difficult construction, and difficult installation, so as to improve economic benefits and improve operability Sexuality and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

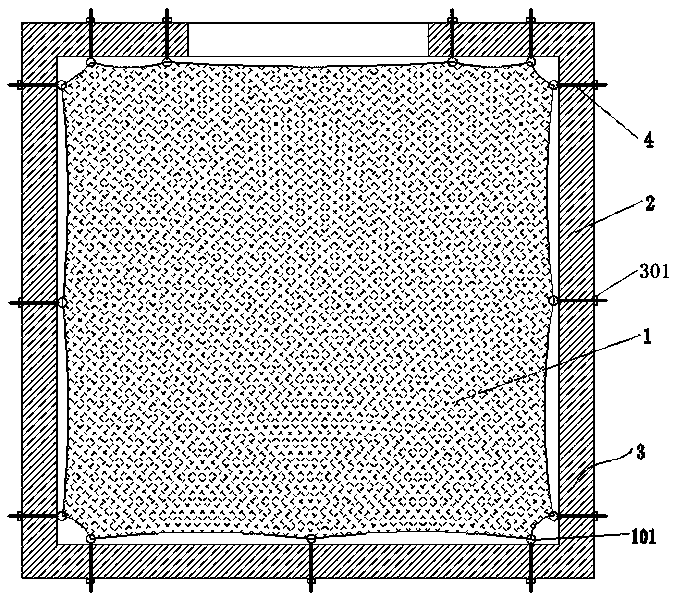

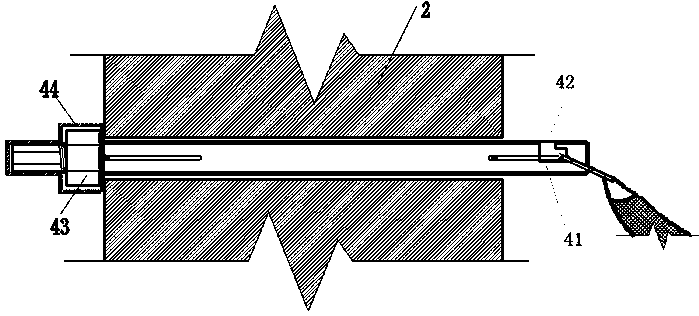

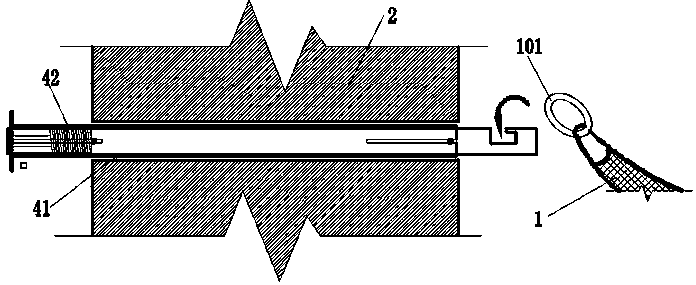

[0029] Such as Figure 1-5 As shown, a kind of elevator shaft anti-falling net structure of the present invention comprises anti-falling net 1 and the connector 4 that anti-falling net 1 is installed on the elevator shaft 3, and the shaft wall 2 of elevator shaft 3 is provided with formwork screw pre-set. Holes 301 are left, and connecting rings 101 are provided at the corresponding positions on the four sides of the anti-falling net 1. The connecting piece 4 includes connecting bolts 41 and sleeves 42. The connecting bolts 41 are movable and tightly fitted in the sleeves 42. There is a connecting ring hanging groove 411, the other end is provided with an external thread and is connected with a nut 43, and the length of the connecting bolt 41 is greater than the length of the sleeve 42, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com