A device for measuring the amount of backflow in coalbed methane exploitation test

A technology for coalbed methane and mining pipes, which is applied in the field of devices for backflow, can solve the problem of inability to measure backflow, and achieve the effect of accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

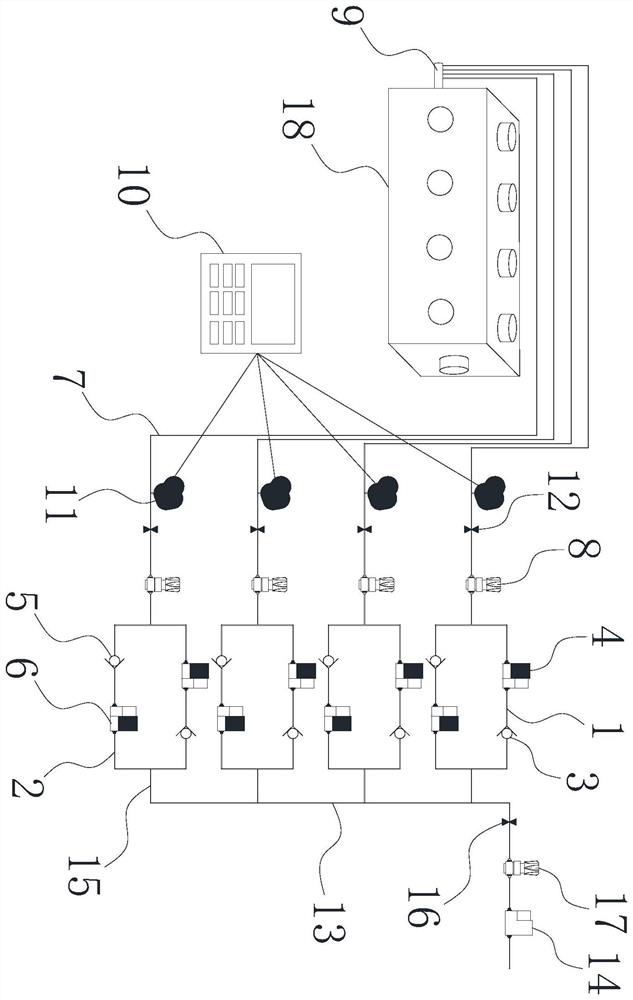

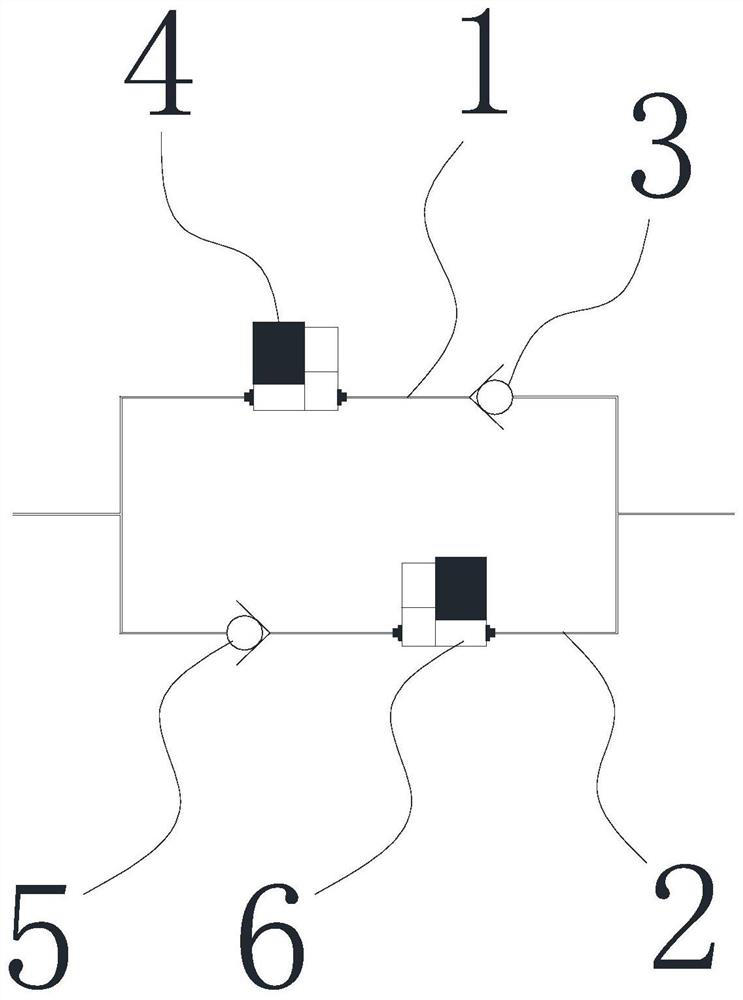

[0042] A device for measuring the amount of backflow during the coalbed methane exploitation test, including several metering mechanisms, the metering mechanism includes a first pipe body 1 and a second pipe body 2 connected in parallel, and the first pipe body 1 is provided with There is a first one-way valve 3 and a first flow meter 4, and the second pipe body 2 is provided with a second one-way valve 5, and the first one-way valve 3 cooperates with the second one-way valve 5 , so that the first pipe body 1 and the second pipe body 2 allow gas to flow in the opposite direction.

[0043] The device for measuring the amount of backflow during the coalbed methane mining test described in the above scheme includes several measuring mechanisms. Before the mining test, one or more measuring mechanisms are selected according to the number of coal seams that need to be simultaneously exploited and tested, so that the number of coal seams Match the number of metering mechanisms, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com