Mixing and paint spraying equipment for mixed paint

A kind of spraying equipment and mixed-type technology, which is applied in the field of mixed-type paint mixing spraying equipment to achieve the effect of reducing the generation of solidification, reducing waste, and avoiding paint residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

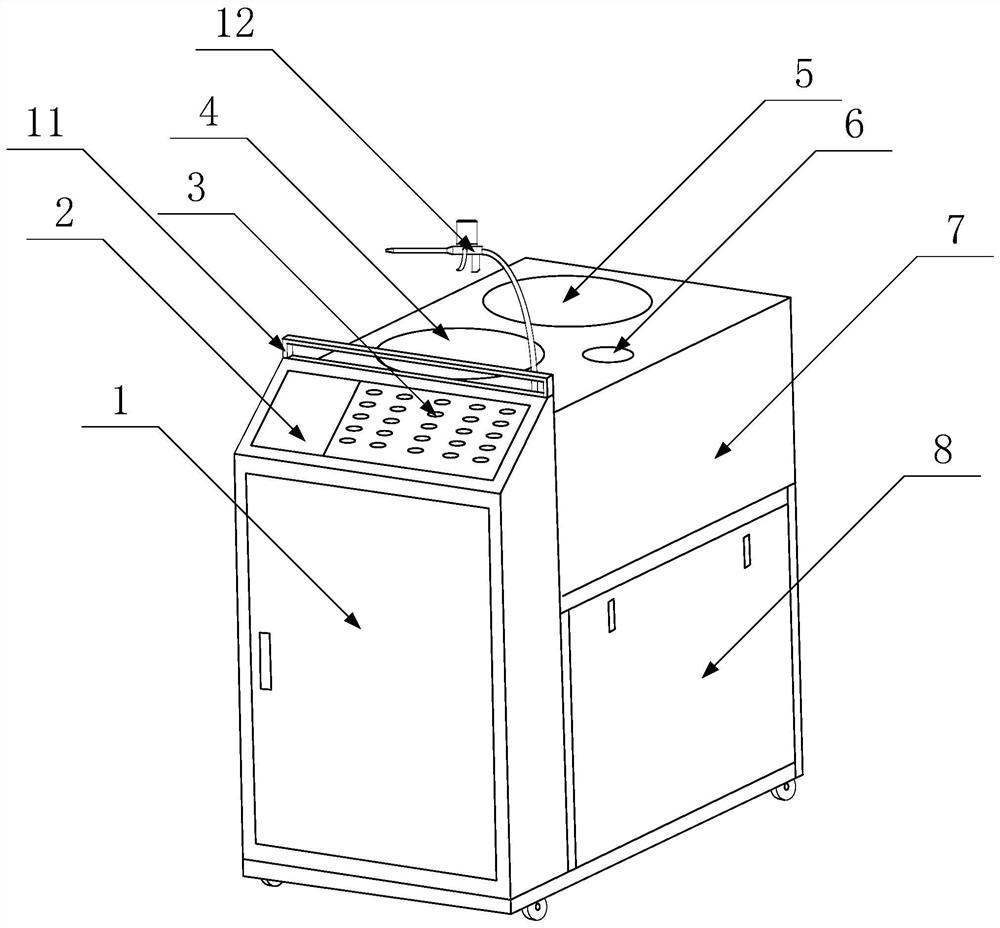

[0027] Such as figure 1 As shown, a mixed paint mixing and spraying equipment includes a control box 1, a display screen 2 arranged on the upper side of the control box 1, an operation panel 3 and an armrest 11, and a lower box body 8 arranged on the back side of the control box 1. The heat insulation box 7 on the back side of the control box 1 and the upper side of the lower box body 8, and the main material bucket 4, the auxiliary material bucket 5, the cleaning tank 6 and the spray gun 12 arranged in the heat insulation box 7.

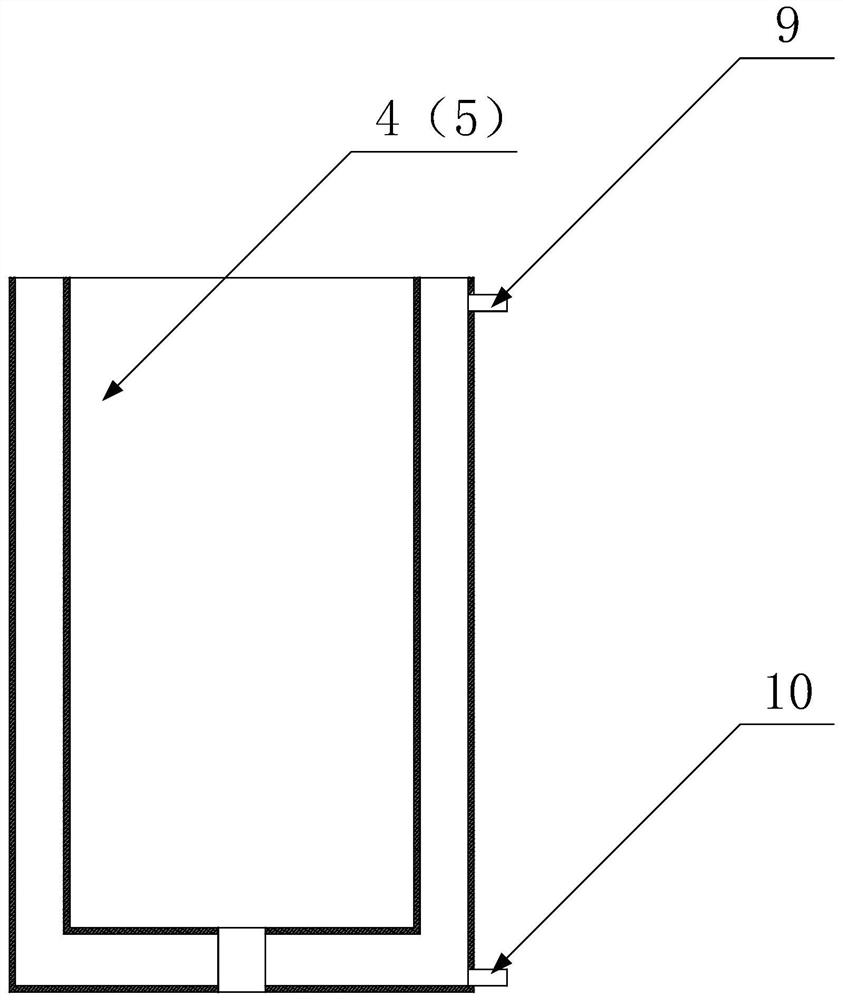

[0028] The tops of the main material barrel 4, the auxiliary material barrel 5 and the cleaning tank 6 all run through the upper side of the heat insulation box 7, and the main material barrel 4 and the auxiliary material barrel 5 are double-layer stainless steel barrels; the main material barrel 4 and the auxiliary material Liquid level gauges are arranged in the barrels 5 .

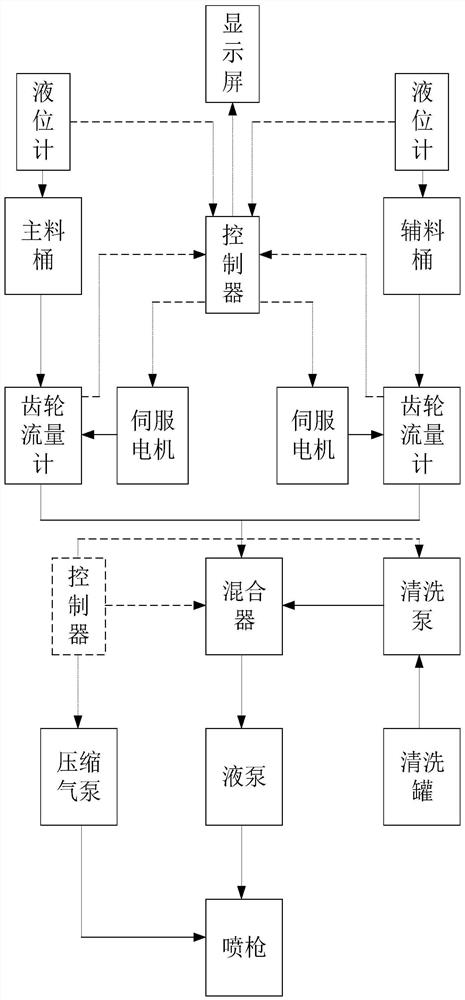

[0029] The control box 1 is provided with a controller, and the control...

Embodiment 2

[0047] The only difference between this embodiment and Embodiment 1 is that the liquid level gauge is a float level gauge.

Embodiment 3

[0049] The product of the present invention can not only be used for mixed type paint, but also can be applied to AB foamed glue. The A glue, the auxiliary material barrel is used to hold the B glue in the AB foam glue.

[0050] Applying the product of this application to the use of AB styrofoam further expands the scope of application of the product and better promotes the promotion and use of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com